Advancements in Thermal Efficiency and Durability

Cutting-Edge Thermal Performance

The latest generation of PU insulation panels has significantly advanced thermal efficiency, pushing the boundaries of building insulation technology. With an impressively low thermal conductivity of just 0.018 W/m·K, these panels deliver unparalleled insulation performance. This outstanding capability results in a high thermal resistance value of approximately 2.09 m²K/W, offering exceptional insulation performance that ensures superior temperature regulation in both hot and cold climates.

With such a high R-value, buildings are able to retain heat efficiently during the winter months and maintain cooler indoor temperatures in the summer. This enhanced thermal control directly contributes to significant reductions in energy consumption and utility bills, while also greatly improving overall occupant comfort throughout the entire year.

Enhanced Durability and Weather Resistance

Later innovative headways have altogether improved the solidness of PU separator boards. The most recent models presently include a wind resistance rating of 8.0 KPa, making them profoundly appropriate for establishment in ranges inclined to solid winds and serious climate conditions. Furthermore, these boards have a strikingly moo waterproof rate of 0.0008, giving great assurance against dampness penetration.

This makes a difference anticipate common issues such as shape development and basic harm. Progressed resistance to weathering, erosion, and UV radiation guarantees that present day PU boards keep up their execution, strength, and appearance for numerous a long time, indeed in unforgiving and challenging situations.

Innovations in Fire Safety and Customization

Advanced Fire-Resistant Properties

One of the most critical headways in PU separator board innovation is the stamped advancement in fire security execution, which upgrades building security by diminishing fire dangers and assembly progressively strict security directions and measures. The most recent boards accomplish fire-protection appraisals of B1 and B2, which give upgraded resistance to start and fire spread.

This imperative advancement addresses one of the essential concerns related with conventional separator materials, making PU boards a more secure and more solid choice. Thus, they have ended up progressively appealing for a wide run of applications, particularly in high-rise buildings, commercial spaces, and other situations where exacting fire security benchmarks are foremost to secure both tenants and property.

Customization and Versatility

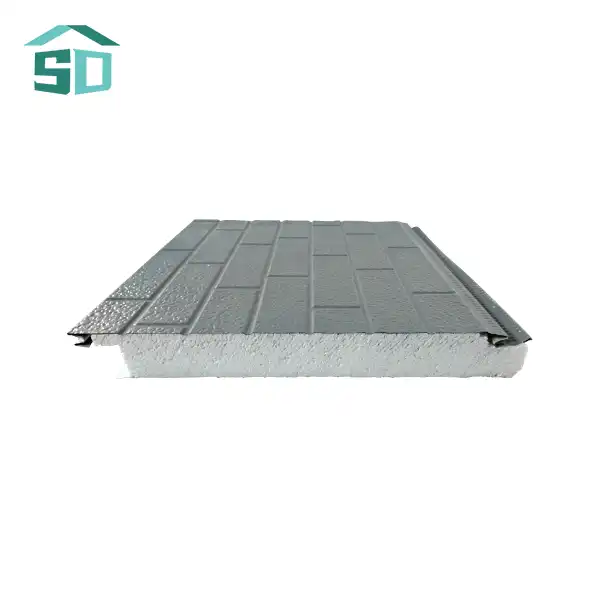

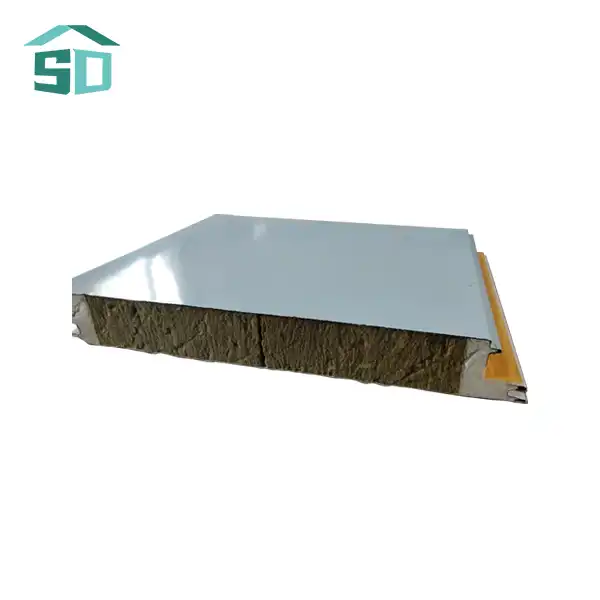

Modern PU insulation panels offer unprecedented levels of customization to meet the diverse needs of various construction projects. Manufacturers now supply panels in a variety of thicknesses tailored to specific applications, ranging from thinner 10mm panels ideal for interior use, up to thicker 16mm or 20mm options designed for exterior insulation.

Width options have also expanded, with exterior panels typically available at 383mm and interior panels at 450mm. Additionally, the surface material thickness can be selected from several options, including 0.23mm, 0.25mm, and 0.27mm. This versatility empowers architects and builders to design unique structures without compromising insulation efficiency.

Environmental Sustainability and Installation Innovations

Eco-Friendly Formulations

In response to growing environmental concerns, the latest PU insulation panel technology incorporates eco-friendly materials and manufacturing processes designed to minimize environmental impact. These advancements significantly reduce the carbon footprint associated with panel production and support green building initiatives worldwide.

By utilizing sustainable raw materials, such as bio-based polyols and recycled components, alongside energy-efficient manufacturing techniques, PU panels have become a more environmentally responsible choice for modern construction projects. This shift not only addresses regulatory demands but also meets the increasing market preference for sustainable building solutions without compromising on insulation performance or durability.

Streamlined Installation Processes

Recognizing the critical importance of efficient and cost-effective installation, manufacturers have developed innovative features that simplify the handling and fitting of PU insulation panels. New interlocking systems ensure precise alignment and secure connections between panels, while lightweight designs reduce physical strain during installation.

These improvements contribute to faster project completion and lower labor costs. Furthermore, advanced adhesives and fastening systems have been introduced to guarantee long-lasting panel attachment and enhanced resistance to environmental stressors. Together, these innovations improve overall system performance and longevity, offering contractors and building owners greater confidence in the durability of their insulation solutions.

Smart Integration Capabilities

The latest generation of PU insulation panels is designed with the demands of smart building technologies in mind, incorporating sensors and connectivity features directly into the panels. These smart panels enable real-time monitoring of critical parameters such as temperature, humidity, and overall energy performance within the building envelope.

This data allows building managers and automated systems to optimize heating, cooling, and ventilation, improving occupant comfort and reducing energy waste. The integration of such technologies marks a significant advancement toward smarter, more efficient buildings by providing actionable insights that support sustainability goals, reduce operational costs, and enhance indoor environmental quality.

Conclusion

The rapid advancements in PU insulation panel technology have transformed these products into high-performance, versatile, and sustainable building materials. From enhanced thermal efficiency and fire resistance to improved customization options and eco-friendly formulations, modern PU panels offer solutions to many of the challenges faced by the construction industry. As technology continues to evolve, we can expect further innovations that will solidify the position of PU insulation panels as a cornerstone of energy-efficient and sustainable building design. For more information on cutting-edge PU insulation panel solutions and how they can benefit your next project, please contact us at info@sdqsc.com.