- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the lightest weight insulation?

When it comes to lightweight insulation, aerogel stands out as the lightest option available. This remarkable material, often called "frozen smoke," boasts an incredibly low density of just 3 kg/m³. However, for practical applications in construction and wall decor, Lightweight Insulation Board emerges as a more viable solution. Combining durability, efficiency, and ease of installation, these boards offer an optimal balance of weight and performance. They provide excellent thermal insulation while remaining significantly lighter than traditional materials, making them an ideal choice for energy-efficient building projects and stylish wall decorations.

The Evolution of Lightweight Insulation Technology

From Traditional to Modern Insulation Solutions

The insulation industry has undergone a significant transformation over the years. Traditional materials like fiberglass and mineral wool have long been staples in construction, but they come with limitations in terms of weight and versatility. The advent of Lightweight Insulation Board marks a pivotal shift in addressing these challenges.

These innovative boards are engineered to provide superior insulation properties while maintaining a fraction of the weight of conventional materials. This advancement has revolutionized the way architects and builders approach both new construction and renovation projects. The reduced weight not only facilitates easier handling and installation but also allows for greater design flexibility in wall decor and overall building aesthetics.

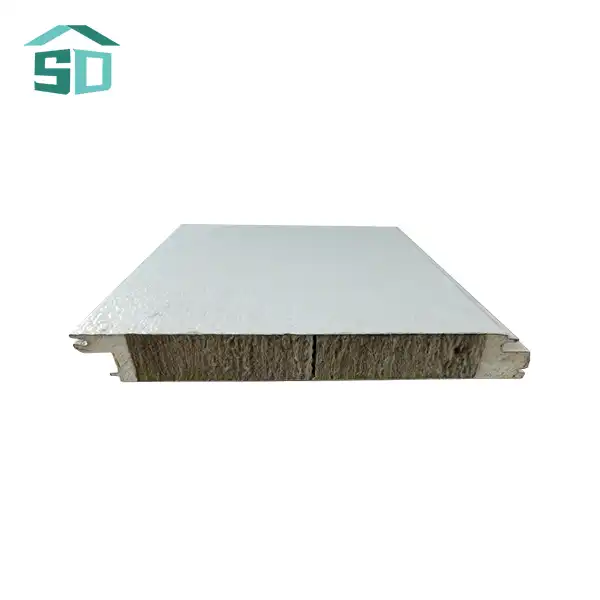

The Science Behind Lightweight Insulation Board

Lightweight Insulation Board owes its exceptional performance to cutting-edge material science. These boards typically consist of a low-density core material, such as expanded polystyrene (EPS) or polyisocyanurate (PIR), sandwiched between protective facings. This composition results in a product that's not only lightweight but also remarkably effective at thermal insulation.

The cellular structure of the core material traps air, creating countless tiny pockets that slow down heat transfer. This design principle mimics nature's most efficient insulators, like animal fur or bird feathers. By harnessing this natural phenomenon, Lightweight Insulation Board achieves excellent R-values (a measure of thermal resistance) while maintaining minimal thickness and weight.

Unparalleled Benefits of Lightweight Insulation Board

Energy Efficiency and Cost Savings

One of the primary advantages of Lightweight Insulation Board is its superior energy efficiency. By effectively reducing heat transfer between the interior and exterior of a building, these boards significantly lower heating and cooling costs. This energy-saving potential not only benefits homeowners and businesses financially but also contribute to reduced carbon emissions, aligning with global sustainability goals.

The cost-effectiveness of Lightweight Insulation Board extends beyond energy savings. Its ease of installation translates to reduced labor costs, while its durability ensures long-term performance with minimal maintenance. This combination of factors makes it an economically sound choice for both new construction and retrofit projects.

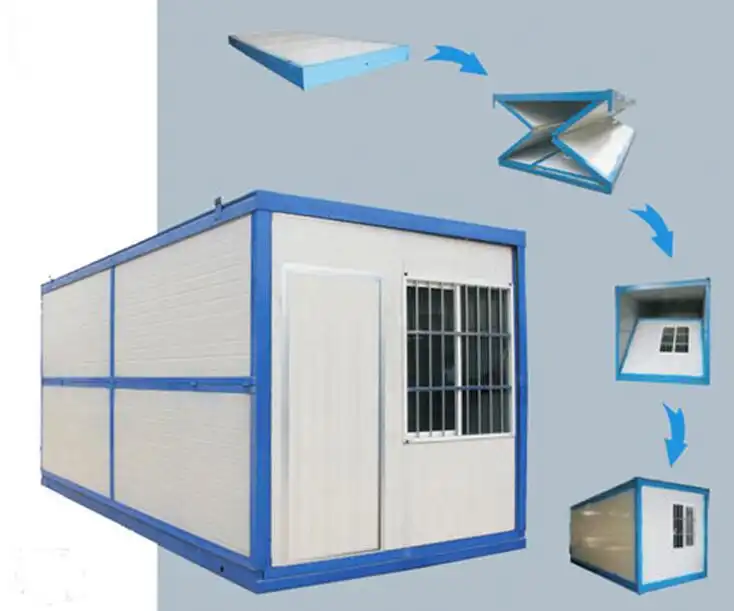

Versatility in Application and Design

Lightweight Insulation Board's adaptability is one of its standout features. These boards can be easily cut, shaped, and customized to fit various architectural designs and wall configurations. This flexibility allows for seamless integration into diverse projects, from residential complexes and office buildings to historic renovations and modern villas.

Moreover, the boards offer extensive options for personalization. They can be manufactured in a wide range of colors and patterns, enabling architects and designers to achieve their desired aesthetic without compromising on insulation performance. This versatility makes Lightweight Insulation Board an excellent choice for both functional insulation and decorative wall treatments.

Advanced Features for Enhanced Performance

Fire Safety and Durability

Safety is paramount in construction, and Lightweight Insulation Board addresses this concern head-on. Many variants of these boards are engineered with flame-resistant properties, significantly enhancing the fire safety of structures. This feature is particularly crucial in high-rise buildings and commercial spaces where fire hazards pose serious risks.

The durability of Lightweight Insulation Board is another key attribute. These boards are designed to withstand harsh environmental conditions, including temperature fluctuations, moisture, and even corrosive elements. This resilience ensures long-lasting performance, reducing the need for frequent replacements and contributing to the overall sustainability of buildings.

Eco-Friendly Manufacturing and Materials

As environmental concerns continue to shape the construction industry, Lightweight Insulation Board steps up to the plate. Many manufacturers are now prioritizing sustainable production methods and materials. Some boards incorporate recycled content or utilize renewable resources in their core materials, reducing the environmental impact of insulation production.

Furthermore, the energy-saving properties of these boards contribute to a building's overall environmental footprint. By reducing the energy required for heating and cooling, Lightweight Insulation Board plays a role in decreasing greenhouse gas emissions associated with building operations. This aligns with green building certifications and helps projects meet stringent environmental standards.

Conclusion

Lightweight Insulation Board represents a significant leap forward in building insulation technology. Its combination of minimal weight, maximum efficiency, and versatile application makes it an invaluable asset in modern construction and renovation projects. From energy savings and aesthetic flexibility to enhanced safety and environmental considerations, these boards offer a comprehensive solution to many challenges faced by architects, builders, and property owners.

As the demand for sustainable, energy-efficient buildings continues to grow, Lightweight Insulation Board is poised to play an increasingly important role in shaping the future of construction. Its ability to seamlessly blend functionality with design opens up new possibilities for creating comfortable, efficient, and visually appealing spaces.

For those interested in exploring the potential of Lightweight Insulation Board for their projects, or to learn more about cutting-edge exterior cladding and facade solutions, don't hesitate to reach out to experts in the field. Contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com for personalized advice and information on how these innovative materials can benefit your next construction or renovation endeavor.

References

1. Baetens, R., Jelle, B. P., & Gustavsen, A. (2011). Aerogel insulation for building applications: A state-of-the-art review. Energy and Buildings, 43(4), 761-769.

2. Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77-86.

3. Jelle, B. P. (2011). Traditional, state-of-the-art and future thermal building insulation materials and solutions – Properties, requirements and possibilities. Energy and Buildings, 43(10), 2549-2563.

4. Schiavoni, S., D'Alessandro, F., Bianchi, F., & Asdrubali, F. (2016). Insulation materials for the building sector: A review and comparative analysis. Renewable and Sustainable Energy Reviews, 62, 988-1011.

5. Berardi, U., & Naldi, M. (2017). The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy and Buildings, 144, 262-275.