- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the difference between PIR and PU sandwich panels?

When it comes to insulation solutions for buildings, PIR (Polyisocyanurate) and PU (Polyurethane) sandwich panels are two popular options that often confuse consumers. The main difference lies in their chemical composition and performance characteristics. PU sandwich panels are made from polyurethane foam, offering excellent insulation properties and flexibility. On the other hand, PIR panels are composed of a modified polyurethane foam with enhanced fire resistance and thermal performance. While both provide effective insulation, PIR panels generally have a slight edge in terms of fire safety and thermal efficiency, whereas PU panels are more versatile and cost-effective for a wider range of applications.

Understanding PU Sandwich Panels: Composition and Benefits

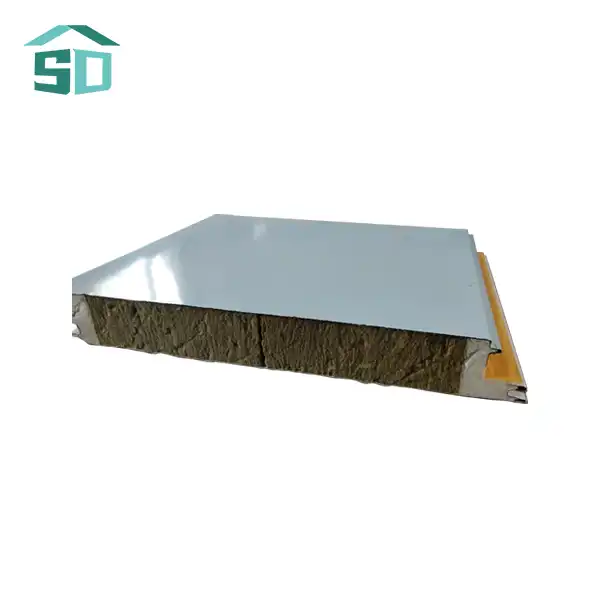

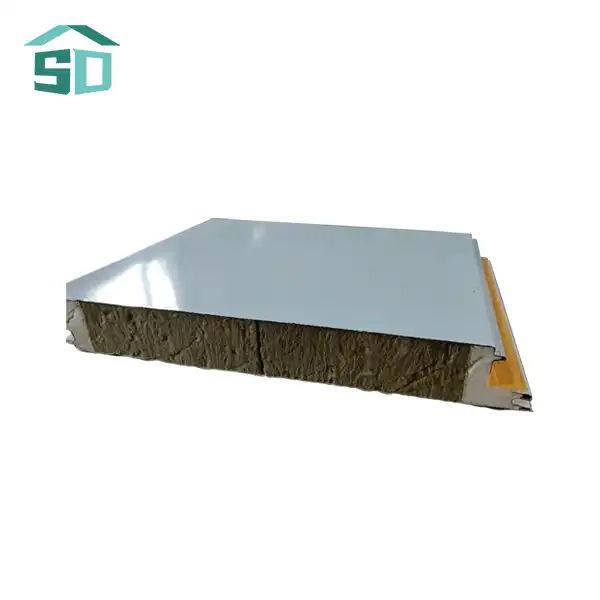

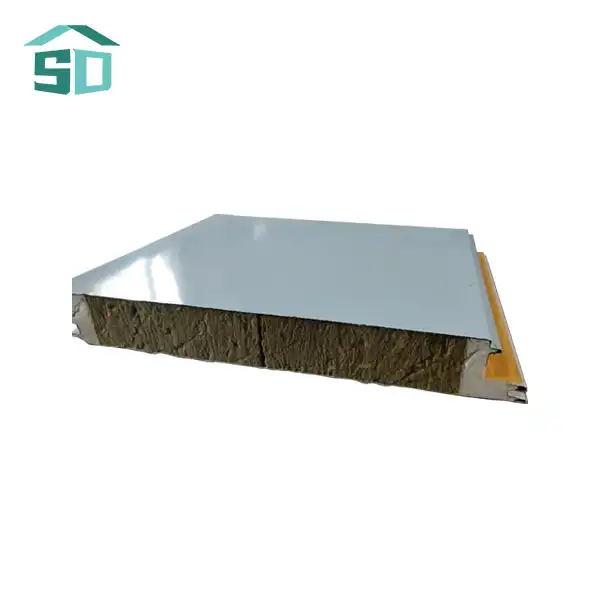

PU sandwich panels have revolutionized the construction industry with their advanced insulation properties and versatile applications. These panels consist of a polyurethane foam core sandwiched between two layers of rigid materials, typically metal sheets. The unique composition of PU sandwich panels contributes to their exceptional performance in various aspects of building construction and maintenance.

Unmatched Durability and Strength

One of the standout features of PU sandwich panels is their remarkable durability. The polyurethane core reinforces the overall structure, providing exceptional strength and longevity to the panel. This enhanced durability makes PU sandwich panels an ideal choice for both interior and exterior wall applications, capable of withstanding harsh environmental conditions and everyday wear and tear.

Superior Thermal Insulation

PU sandwich panels excel in thermal insulation, creating an effective barrier against heat transfer. This property is crucial for maintaining energy-efficient spaces, reducing heating and cooling costs significantly. The exceptional insulation capabilities of PU sandwich panels contribute to creating comfortable indoor environments while minimizing energy consumption.

Fire-Resistant Properties

Safety is paramount in construction, and PU sandwich panels address this concern with their fire-resistant properties. The panels are engineered with flame retardancy in mind, helping to safeguard structures against fire hazards. This feature is particularly valuable in commercial and industrial settings where fire safety regulations are stringent.

Advantages of PU Sandwich Panels in Construction

The benefits of using PU sandwich panels extend beyond their basic composition, offering a range of advantages that make them a preferred choice in modern construction projects. These panels provide excellent thermal insulation due to the polyurethane core, helping to regulate temperatures and reduce energy consumption in buildings. Additionally, their lightweight nature allows for easier handling and installation, saving both time and labor costs. The panels also offer superior soundproofing qualities, making them ideal for buildings where noise reduction is important. Furthermore, PU sandwich panels are highly durable, resistant to moisture, and offer long-lasting performance even in harsh weather conditions. These properties make them not only cost-effective but also a sustainable option for a variety of construction needs.

Corrosion-Free Design

PU sandwich panels boast a corrosion-free design, making them resistant to deterioration even in harsh environments. This quality ensures that the panels maintain their structural integrity and appearance over time, reducing maintenance costs and extending the lifespan of the building envelope. Additionally, their resistance to corrosion helps prevent issues like rust, which can weaken the structure and compromise safety, making them a reliable and low-maintenance option for both residential and commercial projects. The longevity and durability of PU sandwich panels also contribute to the overall sustainability of the building, minimizing the need for frequent replacements or repairs.

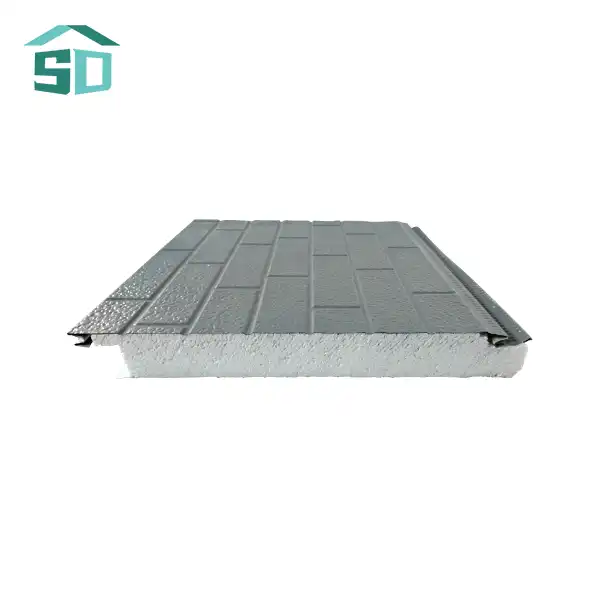

Customizable Aesthetics

Architects and designers appreciate the flexibility that PU sandwich panels offer in terms of aesthetics. These panels can be customized with a wide range of colors and patterns, allowing for unique and personalized decor solutions. This versatility makes PU sandwich panels suitable for various architectural styles and design preferences.

Eco-Friendly Option

In an era of increasing environmental awareness, PU sandwich panels stand out as an eco-friendly option. Many manufacturers now produce these panels using sustainable materials and processes, contributing to greener building practices. The energy efficiency provided by PU sandwich panels also aligns with sustainability goals by reducing overall energy consumption in buildings.

Applications and Performance of PU Sandwich Panels

The versatility of PU sandwich panels makes them suitable for a wide range of applications in the construction industry. Their performance characteristics have made them a popular choice for various types of buildings and structures.

Universal Appeal in Construction

PU sandwich panels find applications in both interior and exterior wall systems. Their adaptability makes them suitable for residential complexes, offices, villas, gardens, and even historic building renovations. The panels' ease of installation and maintenance adds to their appeal across different construction projects.

High-Performance Insulation at Competitive Prices

One of the most compelling aspects of PU sandwich panels is their value proposition. They offer high-performance insulation at competitive prices, making them an attractive option for budget-conscious projects without compromising on quality. This combination of performance and affordability has contributed to the growing popularity of PU sandwich panels in the construction market.

Quality Control and Manufacturing Excellence

Leading manufacturers of PU sandwich panels, such as Wei fang Shandong Building Materials Co., Ltd., are equipped with advanced production lines and rigorous quality control systems. These companies conduct strict testing of raw materials, including steel coils, aluminum foil, and polyurethane. Comprehensive inspections cover product thickness, paint film thickness, mechanical strength, flame retardancy, and overall appearance, ensuring that each panel meets the highest standards of quality and performance.

Conclusion

PU sandwich panels offer a compelling combination of durability, insulation, fire safety, corrosion resistance, customization options, and versatility. These qualities make them an excellent choice for transforming wall decorations and enhancing the overall performance of buildings. As the construction industry continues to evolve, PU sandwich panels are likely to play an increasingly important role in creating efficient, safe, and aesthetically pleasing structures.

For more information about exterior cladding and facade solutions, including PU sandwich panels, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your construction needs.

References

1. Polyurethane Insulation Manufacturers Association. "Polyurethane and PIR Insulation." PIMA, 2021.

2. Building Science Corporation. "Thermal Performance of Insulated Wall Assemblies." BSC, 2020.

3. National Fire Protection Association. "Fire Safety in Building Construction." NFPA, 2022.

4. U.S. Green Building Council. "LEED v4 for Building Design and Construction." USGBC, 2021.

5. American Society for Testing and Materials. "Standard Test Methods for Fire Tests of Building Construction and Materials." ASTM E119-20, 2020.