- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the best thermal insulation panel for walls?

The best thermal insulation panel for walls is a high-performance, multi-functional solution that combines superior thermal insulation, durability, and versatility. These panels, such as those offered by Weifang Sandong Building Materials Co., Ltd., feature advanced materials and designs that significantly reduce heat transfer, enhance energy efficiency, and provide long-lasting protection against the elements. With customizable options, fire-resistant properties, and eco-friendly components, the ideal thermal insulation panel offers a comprehensive solution for both interior and exterior applications, ensuring optimal comfort, safety, and sustainability in various construction projects.

Understanding Thermal Insulation Panels: A Comprehensive Guide

Thermal insulation panels have revolutionized the construction industry, offering a myriad of benefits for both residential and commercial buildings. These innovative solutions provide exceptional thermal performance, contributing to energy conservation and enhanced comfort within structures. Let's delve into the intricacies of thermal insulation panels and explore their significance in modern construction.

What Are Thermal Insulation Panels?

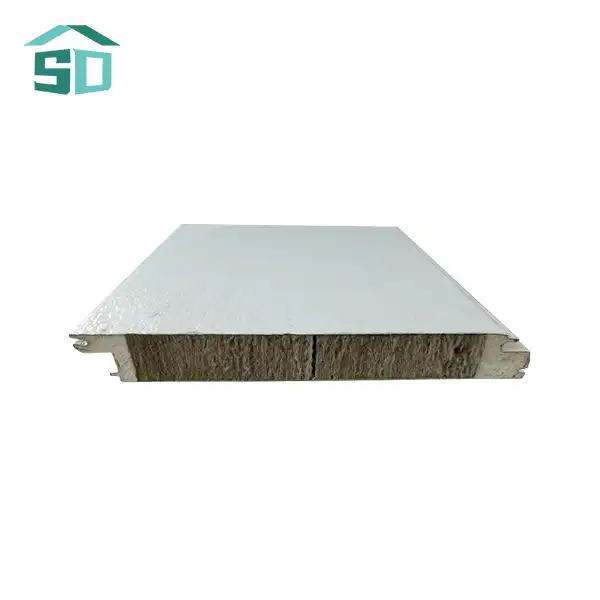

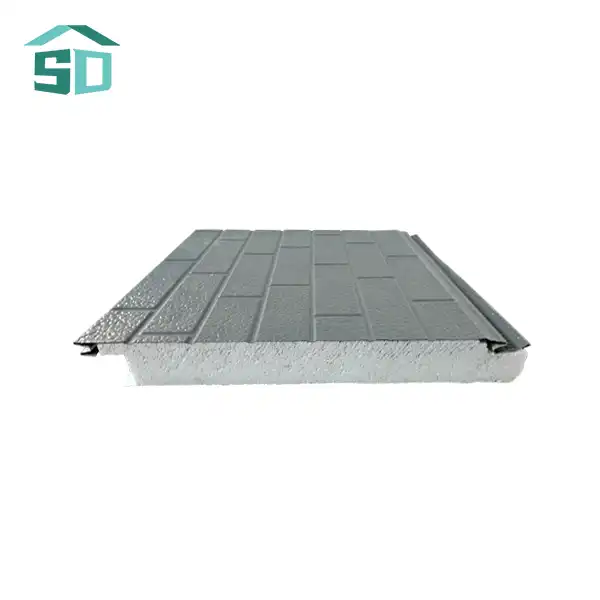

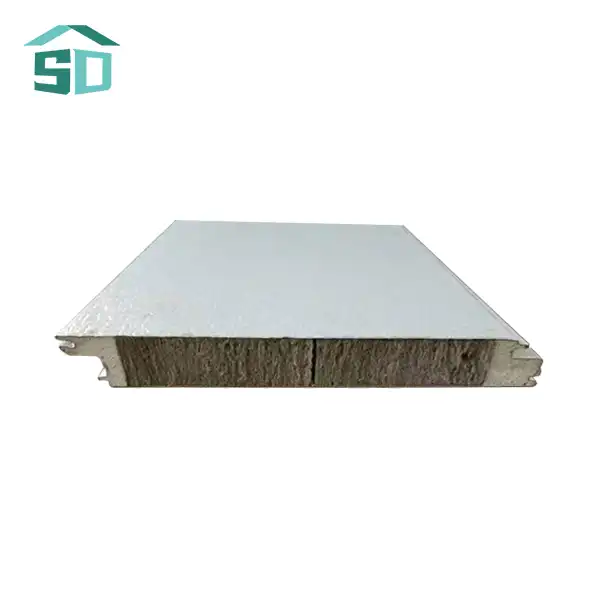

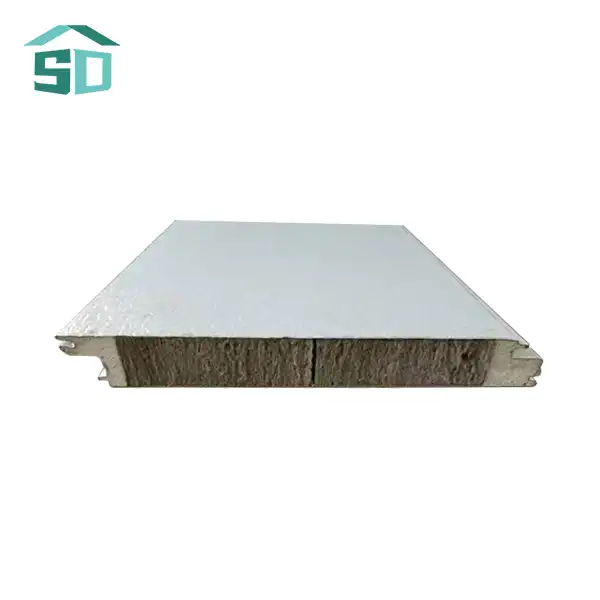

Thermal insulation panels are specialized building materials designed to minimize heat transfer between the interior and exterior of a structure. These panels typically consist of a core insulation material sandwiched between two layers of durable, weather-resistant facing. The core material is often composed of high-performance insulation substances such as polyurethane foam, which boasts impressive thermal conductivity properties.

The viability of warm separator boards is measured by their warm resistance, or R-value. Higher R-values show predominant cover capabilities. For occurrence, the warm separator boards advertised by Weifang Sandong Building Materials Co., Ltd. brag a exceptional warm resistance of 2.09m2k/w, guaranteeing uncommon warm maintenance and vitality productivity.

Key Components of Thermal Insulation Panels

To fully appreciate the functionality of thermal insulation panels, it's crucial to understand their primary components:

- Core Insulation Material: This is the heart of the panel, responsible for its thermal performance. High-quality panels utilize advanced materials with low thermal conductivity, such as the 0.018W/m.k conductivity found in Weifang Sandong's products.

- Facing Materials: The outer layers of the panel provide protection and aesthetic appeal. These can be customized in various colors and patterns to suit architectural preferences.

- Adhesive Layers: These ensure the structural integrity of the panel by bonding the core to the facing materials.

Applications of Thermal Insulation Panels

Thermal insulation panels find diverse applications in the construction sector:

- Exterior Wall Cladding: Panels with a thickness of 16mm or 20mm are ideal for exterior applications, providing both insulation and aesthetic appeal.

- Interior Wall Insulation: Thinner panels, typically 10mm thick, are perfect for enhancing the thermal efficiency of interior spaces without sacrificing room dimensions.

- Roof Insulation: Specialized panels can be used to insulate roofs, further improving a building's overall energy performance.

- Cold Storage Facilities: The superior insulation properties make these panels excellent for maintaining consistent temperatures in refrigerated environments.

Advantages of High-Quality Thermal Insulation Panels

Contributing in premium warm separator boards yields a large number of benefits that amplify distant past simple temperature control. These progressed building materials offer a comprehensive arrangement to different development challenges, making them a crucial component in present day engineering and plan.

Energy Efficiency and Cost Savings

One of the primary advantages of high-quality thermal insulation panels is their ability to significantly reduce energy consumption. By effectively minimizing heat transfer, these panels help maintain consistent indoor temperatures, reducing the load on heating and cooling systems. This translates to substantial energy savings and lower utility bills for building owners and occupants.

The thermal conductivity of 0.018W/m.k, as seen in Weifang Sandong's panels, ensures minimal heat loss or gain through walls. This exceptional insulation performance can lead to energy savings of up to 30% compared to traditional building materials, making thermal insulation panels a cost-effective long-term investment.

Enhanced Durability and Weather Resistance

High-quality warm cover boards are built to withstand cruel natural conditions, guaranteeing life span and steady execution. The strong development of these boards, including corrosion-resistant materials and UV-resistant coatings, gives amazing security against the components.

For instance, panels with a wind resistance of 8.0 Kpa can withstand strong winds and storms, making them suitable for use in diverse climatic conditions. Additionally, the waterproof rate of 0.0008 ensures that moisture penetration is virtually non-existent, preventing issues such as mold growth and structural damage.

Fire Safety and Building Code Compliance

Safety is paramount in construction, and high-quality thermal insulation panels address this concern with advanced fire-resistant properties. Panels rated B1 or B2 for fire protection meet stringent safety standards, providing peace of mind to builders and occupants alike.

These fire-resistant qualities not as it were improve the by and large security of a structure but too guarantee compliance with building codes and controls. This compliance can streamline the endorsement handle for development ventures and possibly diminish protections costs.

Versatility in Design and Application

Modern thermal insulation panels offer unprecedented flexibility in terms of design and application. With customizable colors, patterns, and surface treatments, these panels can be tailored to suit virtually any architectural vision. This versatility allows architects and designers to create visually striking facades without compromising on insulation performance.

The availability of panels in various sizes and thicknesses (such as 383mm width for exterior use and 450mm for interior applications) enables seamless integration into diverse construction projects. From sleek modern office buildings to traditional residential homes, thermal insulation panels can adapt to any design aesthetic.

Installation and Maintenance: Maximizing the Benefits of Thermal Insulation Panels

To fully harness the advantages of thermal insulation panels, proper installation and maintenance are crucial. These aspects not only ensure optimal performance but also extend the lifespan of the panels, maximizing the return on investment for building owners.

Efficient Installation Processes

One of the key benefits of modern thermal insulation panels is their ease of installation. The lightweight design of these panels, coupled with their precise manufacturing, allows for quick and efficient installation processes. This not only reduces labor costs but also minimizes construction timelines, leading to faster project completion.

Professional installation typically involves the following steps:

1. Surface Preparation: Ensuring the substrate is clean, dry, and level.

2. Panel Alignment: Precise positioning of panels to ensure seamless integration and optimal insulation.

3. Secure Fastening: Utilizing appropriate fasteners and adhesives to ensure long-term stability.

4. Joint Sealing: Applying weatherproof sealants to prevent air and moisture infiltration.

5. Final Inspection: Thorough quality checks to ensure proper installation and performance.

The compressive strength of 52.7kpa in high-quality panels ensures that they can withstand the pressures of installation without compromising their structural integrity or insulation properties.

Long-Term Maintenance and Care

While thermal insulation panels are designed for durability and low maintenance, proper care can further extend their lifespan and maintain their effectiveness. Regular maintenance practices include:

- Periodic Inspections: Checking for any signs of damage, such as cracks or separation at joints.

- Cleaning: Gentle cleaning of exterior surfaces to remove dirt and debris that could potentially compromise the panel's performance.

- Resealing: Periodically reapplying sealants at joints and penetrations to ensure continued weatherproofing.

- Prompt Repairs: Addressing any damage or wear promptly to prevent more significant issues.

The corrosion-proof nature of high-quality thermal insulation panels significantly reduces the need for extensive maintenance, making them a cost-effective solution in the long run.

Environmental Considerations and Sustainability

In an era of increasing environmental consciousness, the sustainability aspects of thermal insulation panels cannot be overlooked. Many modern panels are designed with eco-friendly materials and manufacturing processes, aligning with green building standards.

Key environmental benefits include:

- Energy Conservation: By reducing heating and cooling needs, these panels contribute to lower carbon emissions over the building's lifetime.

- Recyclability: Many components of thermal insulation panels can be recycled at the end of their life cycle, reducing waste.

- Longevity: The durability of these panels means less frequent replacement, reducing overall resource consumption.

- Indoor Air Quality: High-quality panels with low VOC emissions contribute to healthier indoor environments.

By choosing sustainable thermal insulation panels, building owners and designers can contribute to environmentally responsible construction practices while enjoying the performance benefits of advanced insulation technology.

Conclusion

Thermal insulation panels represent a significant advancement in building technology, offering a comprehensive solution for energy efficiency, durability, and aesthetic appeal. By providing superior thermal performance, enhanced safety features, and versatile design options, these panels have become an indispensable component in modern construction.

Whether you're embarking on a new construction project or retrofitting an existing structure, investing in high-quality thermal insulation panels can yield substantial benefits in terms of energy savings, comfort, and long-term value. As the construction industry continues to evolve towards more sustainable and efficient practices, thermal insulation panels stand at the forefront of this transformation, paving the way for smarter, more comfortable, and environmentally responsible buildings.

For those seeking to explore the cutting-edge of thermal insulation technology and its applications in exterior cladding and facade solutions, Weifang Sandong Building Materials Co., Ltd. offers a wealth of expertise and innovative products. To learn more about how thermal insulation panels can benefit your next project, don't hesitate to reach out to their team of experts at info@sdqsc.com.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). (2021). ASHRAE Handbook - Fundamentals.

2. International Code Council. (2021). International Energy Conservation Code (IECC).

3. U.S. Department of Energy. (2022). Energy Saver: Insulation.

4. Building Science Corporation. (2020). Guide to Insulating Sheathing.

5. National Institute of Building Sciences. (2021). Whole Building Design Guide: Building Envelope Design Guide.