The Composition and Benefits of Polyurethane Foam Sandwich Panels

Structure and Materials

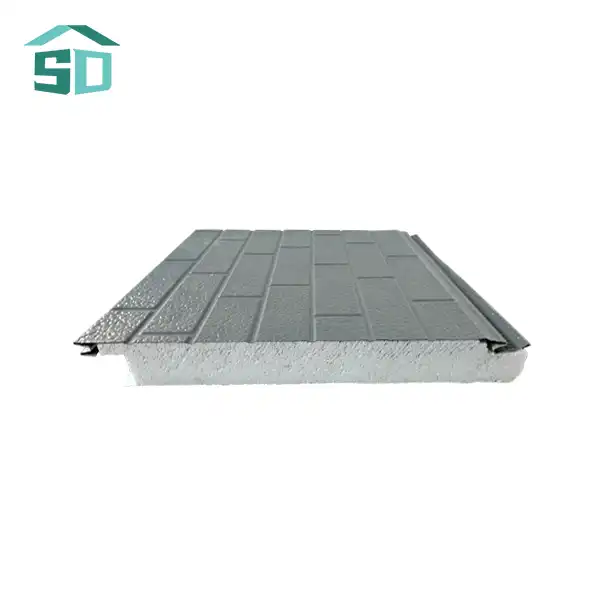

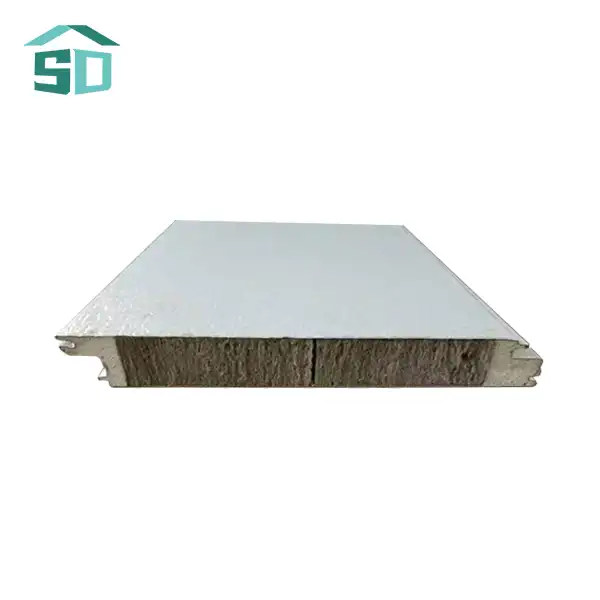

Polyurethane froth sandwich boards are designed composite materials comprising of three primary components: two external confronting sheets and a center of polyurethane froth. The confronting sheets are regularly made of metal, such as steel or aluminum, in spite of the fact that other materials like fiberglass or wood can moreover be utilized depending on the particular application. The center is composed of unbending polyurethane froth, which is known for its great cover properties and basic astuteness.

The manufacturing process involves injecting the liquid polyurethane between the two facing sheets, where it expands and cures to form a solid, uniform core. This results in a strong, lightweight panel that offers a combination of thermal insulation, structural support, and aesthetic appeal.

Key Advantages

Polyurethane froth sandwich boards offer various benefits that make them a prevalent choice in the development industry:

- Exceptional Thermal Insulation: The polyurethane core provides superior heat control, significantly reducing energy consumption in buildings.

- Fire Resistance: Many polyurethane foam formulations incorporate fire-resistant additives, enhancing safety in construction projects.

- Customizable Aesthetics: These panels can be produced in a variety of colors and patterns, allowing for personalized design options.

- Corrosion Resistance: The outer facing sheets can be treated to resist corrosion, ensuring longevity and durability.

- Energy Efficiency: The high insulation value of PU foam panels contributes to substantial energy savings over time.

- Versatility: Suitable for both interior and exterior applications, these panels offer flexibility in design and construction.

Applications and Uses of Polyurethane Foam Sandwich Panels

Building and Construction

In the construction industry, polyurethane foam sandwich panels have become increasingly popular due to their versatility and performance. They are commonly used in:

- Wall Systems: As exterior cladding or interior wall partitions, providing both insulation and structural support.

- Roofing: Offering excellent insulation and weather resistance for various types of roofs.

- Flooring: Particularly in raised floor systems where insulation and lightweight properties are crucial.

- Modular Construction: Ideal for prefabricated buildings due to their ease of installation and thermal efficiency.

These panels are particularly beneficial in green building projects, where energy efficiency and sustainable materials are paramount. Their ability to reduce heating and cooling costs aligns well with eco-friendly construction practices.

Industrial and Commercial Applications

Beyond traditional construction, polyurethane foam sandwich panels find extensive use in various industrial and commercial settings:

- Cold Storage Facilities: The exceptional insulation properties make these panels ideal for maintaining consistent low temperatures in warehouses and distribution centers.

- Refrigerated Transport: Used in the construction of truck bodies and shipping containers for temperature-sensitive goods.

- Agricultural Buildings: Providing insulation and durability for livestock housing, grain storage, and other agricultural structures.

- Clean Rooms: The smooth, easy-to-clean surfaces of these panels make them suitable for pharmaceutical and electronic manufacturing facilities.

Specialized Uses

The versatility of polyurethane foam sandwich panels extends to more specialized applications:

- Marine Industry: Used in boat hulls and yacht interiors for their lightweight and insulative properties.

- Aerospace: Employed in aircraft interiors and cargo holds due to their fire-resistant and lightweight characteristics.

- Soundproofing: The dense foam core provides excellent sound insulation, making these panels useful in recording studios and noise-sensitive environments.

Installation, Maintenance, and Future Trends

Effortless Installation Process

One of the key advantages of polyurethane foam sandwich panels is their ease of installation. The lightweight nature of these boards, combined with their interlocking plan, permits for speedy and productive gathering. This not only reduces construction time but also minimizes labor costs. The installation process typically involves:

- Preparing the structural framework

- Aligning and securing the panels using specialized fasteners

- Sealing joints and connections to ensure airtightness and weather resistance

Many manufacturers provide detailed installation guides and offer technical support to ensure proper installation, maximizing the panels' performance and longevity.

Maintenance and Longevity

Polyurethane foam sandwich panels are renowned for their low maintenance requirements and durability. To ensure optimal performance and extend the lifespan of these panels:

- Regularly inspect for any signs of damage or wear

- Clean the surface using mild detergents and soft brushes to prevent accumulation of dirt and debris

- Promptly address any issues with seals or joints to maintain the panel's insulative properties

- Repaint or recoat exterior panels as needed to protect against UV degradation and maintain aesthetic appeal

With proper care, polyurethane foam sandwich panels can maintain their performance and appearance for decades, offering excellent return on investment for building owners.

Emerging Trends and Innovations

The field of polyurethane foam sandwich panels continues to evolve, with several exciting trends emerging:

- Enhanced Fire Resistance: Ongoing research is focused on developing even more fire-resistant formulations without compromising insulation properties.

- Eco-Friendly Formulations: Manufacturers are exploring bio-based polyurethanes and recycled materials to reduce environmental impact.

- Smart Panels: Integration of sensors and smart technologies into panels for real-time monitoring of building performance.

- Improved Thermal Performance: Development of new foam compositions to further enhance insulation capabilities.

- Aesthetic Innovations: Advanced printing and texturing techniques to expand design possibilities.

These advancements are poised to further cement the position of polyurethane foam sandwich panels as a cornerstone of modern, efficient construction.

Conclusion

Polyurethane foam sandwich panels represent a significant advancement in building materials, offering a unique combination of thermal efficiency, structural integrity, and design flexibility. Their widespread adoption across various industries underscores their versatility and effectiveness. As construction trends continue to prioritize energy efficiency and sustainable practices, these panels are likely to play an increasingly important role in shaping the built environment of the future.

For those interested in learning more about polyurethane foam sandwich panels and their applications in exterior cladding and facade solutions, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To explore how these innovative materials can benefit your next project, please contact us at info@sdqsc.com.