The Composition and Manufacturing of Polyurethane Sandwich PUF Panels

Polyurethane sandwich PUF panels are meticulously crafted using cutting-edge technology and high-quality materials. The manufacturing process involves several key steps to ensure the panels meet rigorous standards for performance and durability.

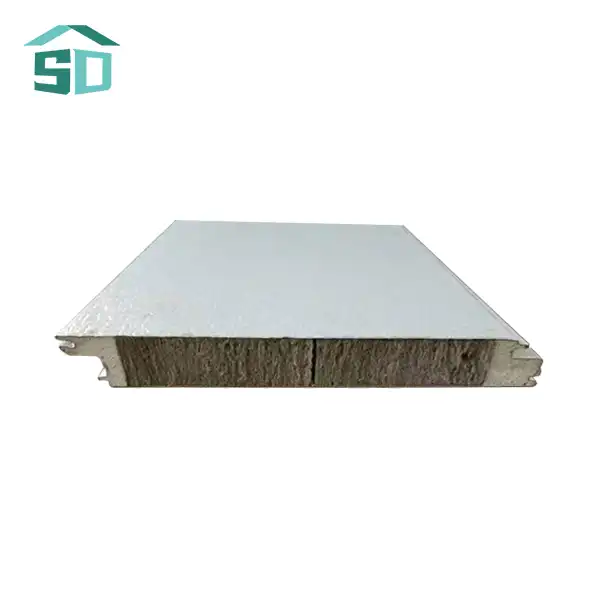

Core Materials and Structure

The heart of a polyurethane sandwich PUF panel is its insulating core. This center is composed of polyurethane froth, a flexible fabric known for its extraordinary warm properties. The froth is made through a chemical response between polyol and isocyanate, which grows to fill the space between the external layers.

The thickness and composition of the froth can be balanced to meet particular prerequisites for warm conductivity, fire resistance, and auxiliary quality. Ordinarily, the froth center has a warm conductivity as moo as 0.018W/m.k, making it an great separators against warm exchange.

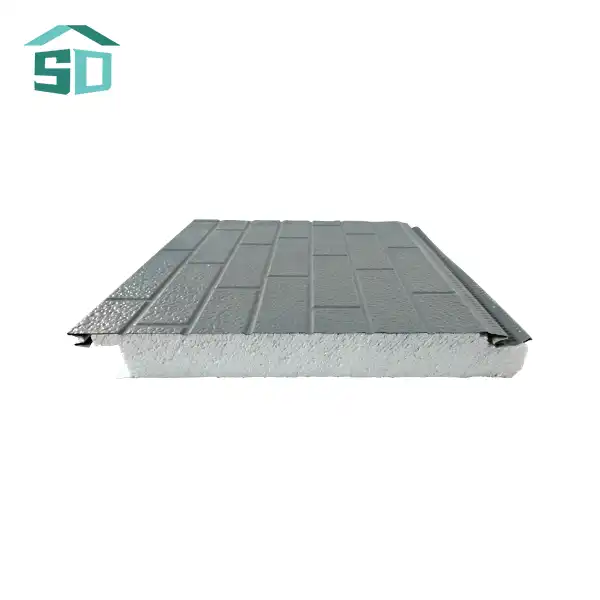

Outer Layers and Finishes

The exterior faces of polyurethane sandwich PUF panels are typically made of metal, such as steel or aluminum. These metal sheets are often pre-coated or treated to enhance their resistance to corrosion and UV radiation. The thickness of these outer layers can vary, with common options ranging from 0.23mm to 0.27mm.

One of the focal points of polyurethane sandwich PUF boards is their plan adaptability. Producers offer a wide extend of colors, surfaces, and wraps up to coordinate different engineering styles and venture prerequisites. This flexibility permits designers and builders to accomplish both utilitarian and tasteful objectives without compromising on execution.

Production Process and Quality Control

The production of polyurethane sandwich PUF panels involves sophisticated machinery and strict quality control measures. Advanced production lines ensure consistent panel thickness and uniform foam distribution. Quality control systems meticulously test various aspects of the panels, including thickness, paint film integrity, mechanical strength, flame retardancy, and overall appearance.

This rigorous manufacturing process results in panels that are not only high-performing but also reliable and long-lasting. The attention to detail in production contributes to the panels' ability to withstand harsh weather conditions and maintain their insulative properties over time.

Key Features and Benefits of Polyurethane Sandwich PUF Panels

Polyurethane sandwich PUF panels offer a myriad of advantages that make them an attractive choice for modern construction projects. Their unique combination of properties addresses many of the challenges faced in building design and energy efficiency.

Thermal Insulation Excellence

One of the most significant benefits of polyurethane sandwich PUF panels is their superior thermal insulation capabilities. With a thermal conductivity of just 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels are exceptionally effective at maintaining ideal indoor temperatures year-round. This high-performance insulation translates to substantial energy savings, reducing both heating and cooling costs for building owners.

Lightweight Yet Durable Construction

Despite their robust insulation properties, polyurethane sandwich PUF panels are remarkably lightweight. This characteristic makes them easy to handle, transport, and install, potentially reducing construction time and labor costs. However, their light weight does not compromise their strength. With a compressive strength of 52.7kpa, these panels can withstand significant loads and pressures.

Fire and Moisture Resistance

Safety is a paramount concern in building materials, and polyurethane sandwich PUF panels address this with their impressive fire-resistant properties. Meeting B1/B2 fire safety standards, these panels provide an additional layer of protection against fire spread. Moreover, their exceptional waterproof rate of 0.0008 ensures that moisture penetration is minimized, protecting the building's interior from water damage and mold growth.

Wind Resistance and Structural Integrity

In areas prone to high winds or severe weather, the stability of building materials is crucial. Polyurethane sandwich PUF panels excel in this aspect, capable of withstanding wind pressures up to 8.0 Kpa. This resilience ensures that structures remain secure even in challenging environmental conditions, providing peace of mind to building owners and occupants alike.

Customization and Versatility

The versatility of polyurethane sandwich PUF boards is one of their most appealing highlights. Accessible in a run of sizes, thicknesses, and wraps up, these boards can be custom fitted to meet the particular needs of any venture. Ordinary measurements incorporate insides thicknesses of 10mm and outside thicknesses of 16mm or 20mm, with widths shifting from 383mm for outside applications to 450mm for insides utilize. This adaptability permits for consistent integration into assorted building plans and development prerequisites.

Applications and Industry Impact of Polyurethane Sandwich PUF Panels

The versatility and performance of polyurethane sandwich PUF panels have led to their widespread adoption across various sectors of the construction industry. Their impact is felt in both new construction and renovation projects, offering solutions that combine functionality with aesthetic appeal.

Residential and Commercial Buildings

In residential construction, polyurethane sandwich PUF panels are increasingly used for exterior walls, roofing, and interior partitions. Their excellent insulation properties contribute to more energy-efficient homes, while their customizable finishes allow for diverse architectural expressions. Similarly, in commercial buildings, these panels are prized for their ability to create large, open spaces with minimal structural support, all while maintaining optimal thermal conditions.

Industrial and Agricultural Structures

The strength and cover properties of polyurethane sandwich PUF boards make them perfect for mechanical and agrarian applications. Stockrooms, production lines, and cold capacity offices advantage from the panels' capacity to keep up steady inside temperatures, pivotal for stock administration and operational proficiency. In agricultural settings, these panels are used in the construction of barns, greenhouses, and storage facilities, providing a controlled environment for livestock and crops.

Modular and Prefabricated Construction

The lightweight nature and ease of installation of polyurethane sandwich PUF panels have made them a favorite in the growing field of modular and prefabricated construction. These panels allow for rapid assembly of building components off-site, reducing construction time and on-site labor costs. This efficiency is particularly valuable in projects with tight deadlines or in remote locations where traditional construction methods may be challenging.

Renovation and Retrofit Projects

Polyurethane sandwich PUF panels are not limited to new construction. They are increasingly used in renovation and retrofit projects, offering a way to significantly improve the energy efficiency and appearance of existing buildings. Their lightweight nature means they can often be installed over existing structures without the need for extensive modifications to the building's framework.

Conclusion

Polyurethane sandwich PUF panels represent a significant advancement in building materials technology. Their combination of thermal efficiency, structural strength, and design flexibility makes them an invaluable asset in modern construction. As the industry continues to prioritize energy efficiency and sustainable building practices, these panels are likely to play an increasingly important role in shaping the built environment of the future.

For more information about our polyurethane sandwich PUF panels and other exterior cladding and facade solutions, please don't hesitate to contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect solution for your construction needs.