The Anatomy of Corrugated Sandwich Panels: A Deep Dive into Their Structure and Components

To truly appreciate the imagination behind Corrugated Sandwich Panels, it's essential to understand their intricate structure and the paraphernalia used in their construction. These panels are a phenomenon of engineering, designed to maximize strength while minimizing weight and material operation.

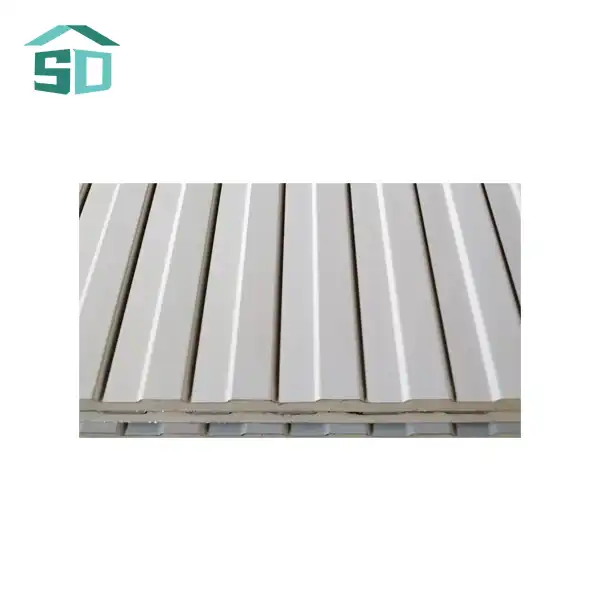

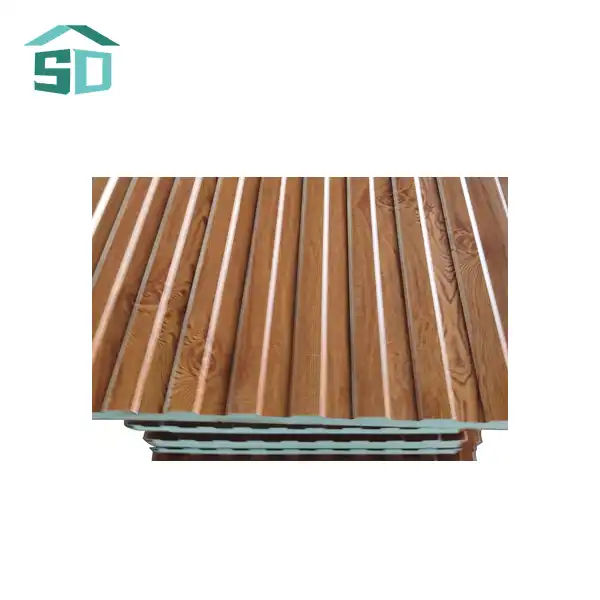

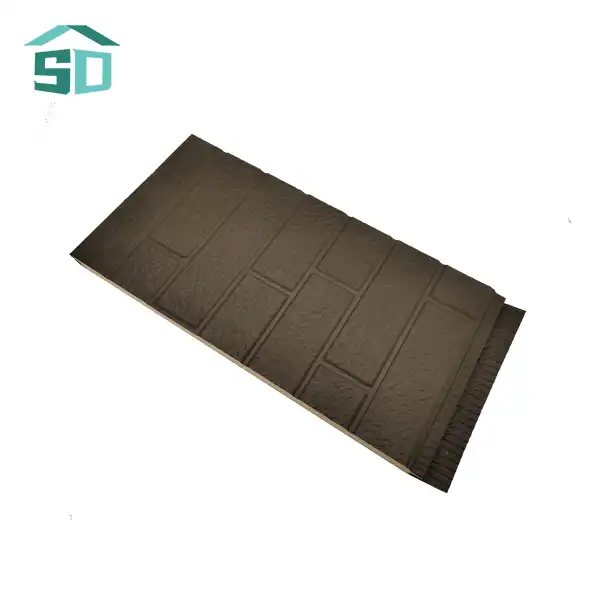

Face Sheets: The Protective Outer Layers

The face sheets of a Corrugated Sandwich Panel serve as the protective outer layers, providing durability and aesthetic appeal. These sheets are typically made from materials such as steel, aluminum, or fiber-reinforced composites. The choice of material depends on the specific application and desired properties of the panel.

Steel face sheets offer exceptional strength and corrosion resistance, making them ideal for exterior cladding in harsh environments. Aluminum sheets, on the other hand, provide a lightweight alternative without compromising on durability. For applications requiring even lighter weight or specific performance characteristics, fiber-reinforced composites can be utilized.

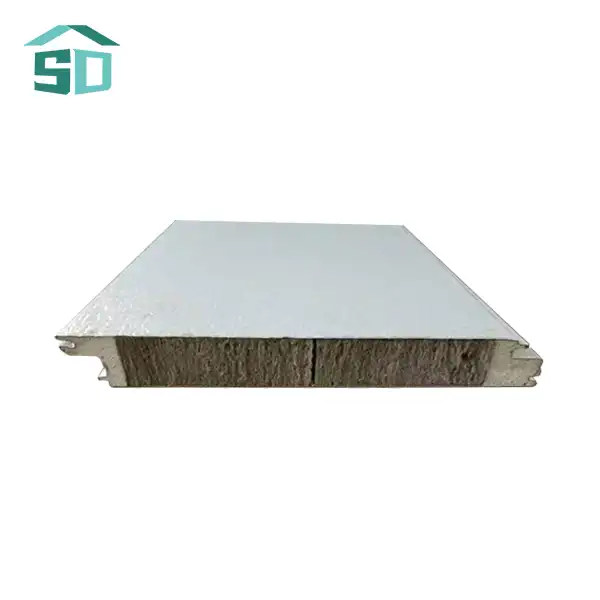

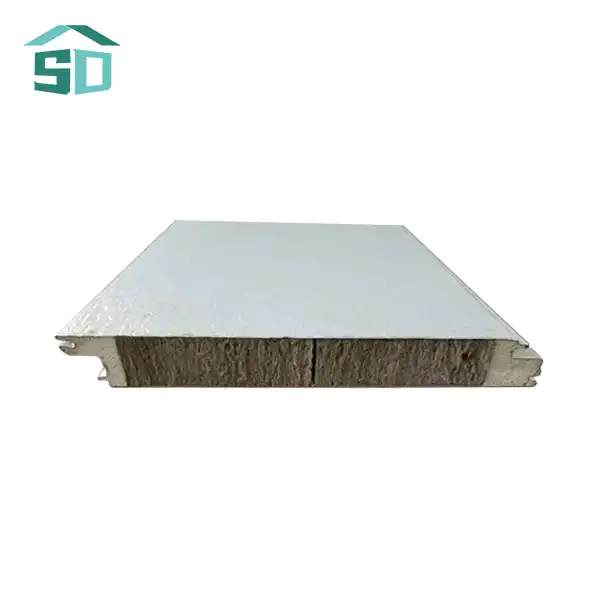

Corrugated Core: The Heart of the Panel

The corrugated core is the defining feature of these panels, giving them their unique properties. This core is typically made from the same material as the face sheets, creating a homogeneous structure that ensures consistent thermal expansion and contraction.

The corrugated design of the core serves multiple purposes:

- Structural Integrity: The wave-like pattern of the core provides exceptional compressive and shear strength, allowing the panel to withstand significant loads.

- Weight Reduction: The open spaces within the corrugated structure significantly reduce the overall weight of the panel without compromising its strength.

- Thermal Insulation: The air pockets created by the corrugated design act as natural insulators, enhancing the panel's thermal performance.

- Acoustic Performance: The corrugated structure also helps in dampening sound waves, improving the panel's acoustic insulation properties.

Bonding Agents: The Invisible Strength

The face sheets and corrugated core are held together by high-performance adhesives or welding techniques. These bonding methods ensure that the components work together as a single unit, distributing loads evenly across the panel. The choice of bonding agent depends on the materials used and the specific requirements of the application.

Applications and Advantages: Harnessing the Power of Corrugated Sandwich Panels

The unique properties of Corrugated Sandwich Panels make them suitable for a wide range of applications across various industries. Their versatility and performance characteristics have led to their increasing adoption in modern construction and engineering projects.

Construction Industry: Revolutionizing Building Envelopes

In the construction sector, Corrugated Sandwich Panels have become a game-changer for building envelopes. Their superior insulation properties contribute significantly to energy efficiency, helping to reduce heating and cooling costs. The panels' fire-retardant properties also enhance building safety, making them an excellent choice for both residential and commercial structures.

The customizable nature of these panels allows engineers and contrivers to produce unique facades with a variety of colors and patterns. This flexibility in design, coupled with the panels' durability and low maintenance requirements, makes them an attractive option for modern architectural projects.

Industrial Applications: Enhancing Efficiency and Safety

In industrial settings, Corrugated Sandwich Panels find applications in the construction of warehouse walls, roofs, and partitions. Their excellent thermal insulation properties help maintain stable temperatures in storage facilities, protecting sensitive goods and reducing energy costs.

The panels' erosion- resistant parcels make them particularly suitable for use in harsh surroundings, similar as chemical shops or littoral areas. Their capability to repel extreme rainfall conditions ensures long- term continuity and reduces conservation costs.

Transportation and Aerospace: Lightweight Solutions for Mobile Applications

The transportation and aerospace industries benefit from the lightweight yet strong nature of Corrugated Sandwich Panels. In the automotive sector, these panels are used to create lightweight body panels and interior components, contributing to improved fuel efficiency.

In aerospace applications, Corrugated Sandwich Panels are used in aircraft interiors, cargo containers, and even structural components.Their high strength- to- weight rate makes them ideal for operations where weight reduction is pivotal without compromising on structural integrity.

Manufacturing Process and Quality Control: Ensuring Excellence in Every Panel

The production of high-quality Corrugated Sandwich Panels requires advanced manufacturing techniques and rigorous quality control measures. At Weifang Sandong Building Materials Co., Ltd., we have invested in state-of-the-art production lines and implemented comprehensive quality assurance protocols to ensure that every panel meets the highest standards of performance and durability.

Advanced Production Techniques

Our manufacturing process begins with the careful selection of raw materials. We source high-quality steel coils, aluminum foil, and polyurethane from trusted suppliers to ensure the integrity of our panels from the ground up. The production line is equipped with precision machinery that forms the corrugated core and bonds it to the face sheets with exact tolerances.

The corrugation process is carefully controlled to achieve the optimal wave pattern that balances strength, weight, and insulation properties. Advanced bonding techniques, including high-performance adhesives and precision welding, are used to create a seamless union between the core and face sheets.

Rigorous Quality Control

Quality control is at the heart of our manufacturing process. Each stage of product is covered and tested to insure compliance with transnational norms and our own strict quality criteria. Our comprehensive examination process includes:

- Material Testing: Raw accoutrements are tested for composition, strength, and chastity before entering the product line.

- Dimensional Accuracy: Panel thickness, corrugation depth, and overall dimensions are precisely measured to ensure consistency.

- Coating Integrity: For panels with protective coatings, we conduct thorough tests on paint film thickness and adhesion.

- Mechanical Strength: Panels undergo rigorous testing to verify their load-bearing capacity, flexural strength, and impact resistance.

- Flame Retardancy: Fire resistance tests are conducted to ensure compliance with safety standards.

- Visual Inspection: Each panel is carefully examined for surface defects, color consistency, and overall appearance.

This meticulous approach to quality control ensures that every Corrugated Sandwich Panel that leaves our facility meets the highest standards of performance, durability, and aesthetic appeal.

Customization and Innovation

Our commitment to excellence extends beyond standard production. We offer customized solutions to meet the unique requirements of each project. Our team of engineers and designers works closely with clients to develop tailor-made panels that address specific performance needs, aesthetic preferences, or installation challenges.

Continuous innovation is a cornerstone of our approach. We invest in research and development to explore new materials, manufacturing techniques, and panel designs that push the boundaries of what's possible with Corrugated Sandwich Panels.

Conclusion

Corrugated Sandwich Panels represent a significant advancement in building materials, offering a unique combination of strength, lightweight properties, and versatility. Their innovative structure, combining rigid face sheets with a corrugated core, provides exceptional performance across a wide range of applications, from construction to aerospace.

At Weifang Sandong Building Materials Co., Ltd., we are committed to delivering the highest quality Corrugated Sandwich Panels to meet the evolving needs of the construction industry.Our advanced manufacturing processes, rigorous quality control measures, and fidelity to customization insure that each panel we produce meets the loftiest norms of performance and continuity.

As the demand for energy-effective, durable, and aesthetically pleasing structure accoutrements continues to grow, Corrugated Sandwich Panels are poised to play an decreasingly important part in shaping the future of construction and engineering. Their ability to combine form and function, coupled with their eco-friendly properties, makes them an ideal choice for forward-thinking architects, builders, and engineers. For more information about our Corrugated Sandwich Panels and how they can benefit your next project, please don't hesitate to contact us at info@sdqsc.com.