The Anatomy and Benefits of Thermal Insulation Panels

Structure and Composition

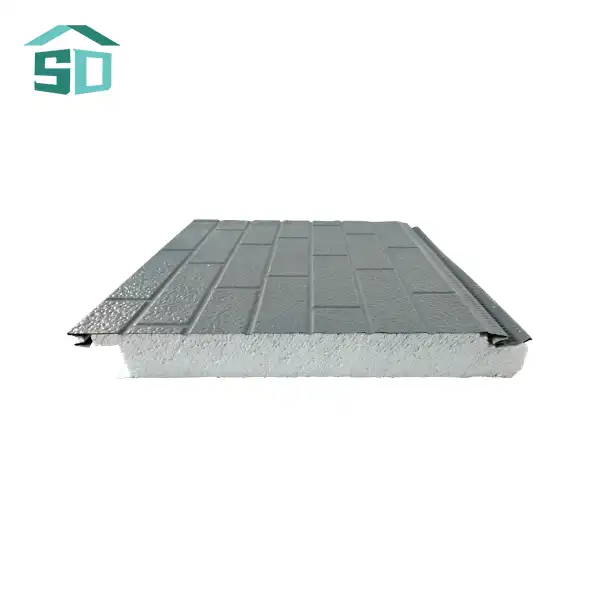

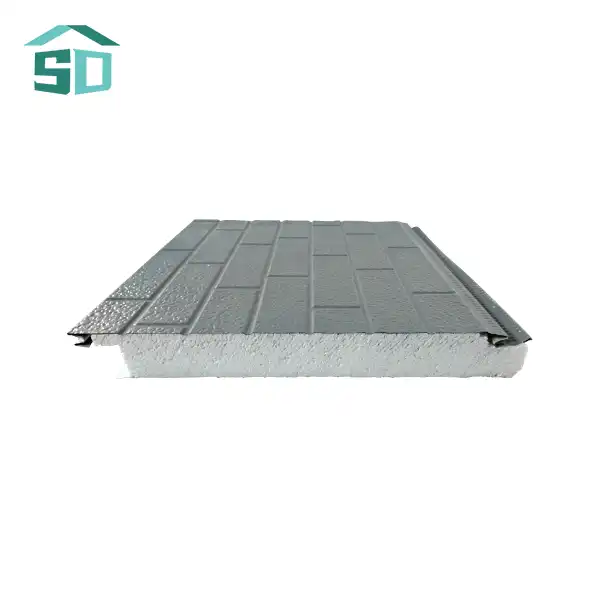

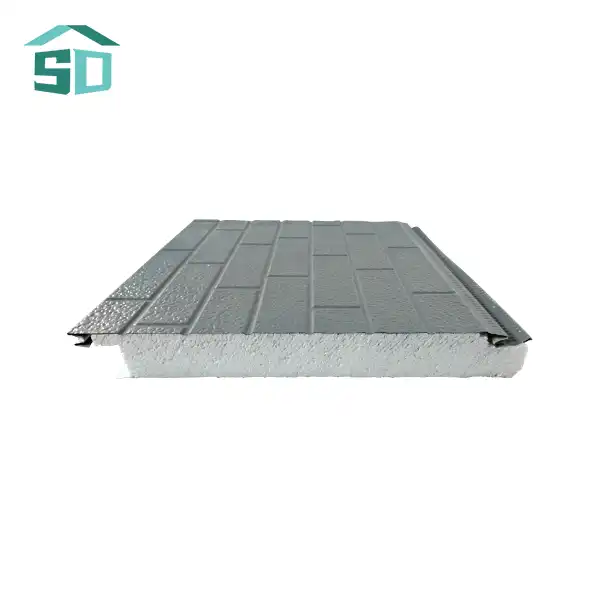

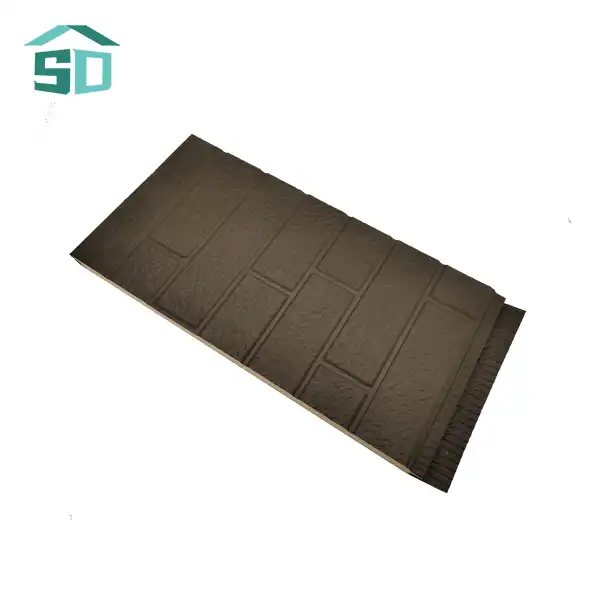

Warm separator boards are designed with a multi-layered structure that maximizes their protection capabilities. At the center of these boards lies a high-performance separator fabric, regularly polyurethane froth, which gloats uncommon warm conductivity properties. This center is encased between two layers of defensive confronting materials, which can change depending on the particular application and tasteful prerequisites.

The confronting materials play a vital part in the in general execution of the boards. They not as it were give auxiliary judgment but moreover contribute to the panels' solidness, fire resistance, and climate security. Common confronting materials incorporate steel, aluminum, and different polymer composites. The thickness of these surface materials can run from 0.23mm to 0.27mm, striking a adjust between quality and weight.

Unparalleled Insulation Performance

The hallmark of thermal insulation panels is their superior insulating capacity. With a thermal conductivity as low as 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels create an effective barrier against heat transfer. This exceptional performance translates to significant energy savings for both heating and cooling, making them an ideal choice for energy-conscious builders and homeowners.

Versatility in Design and Application

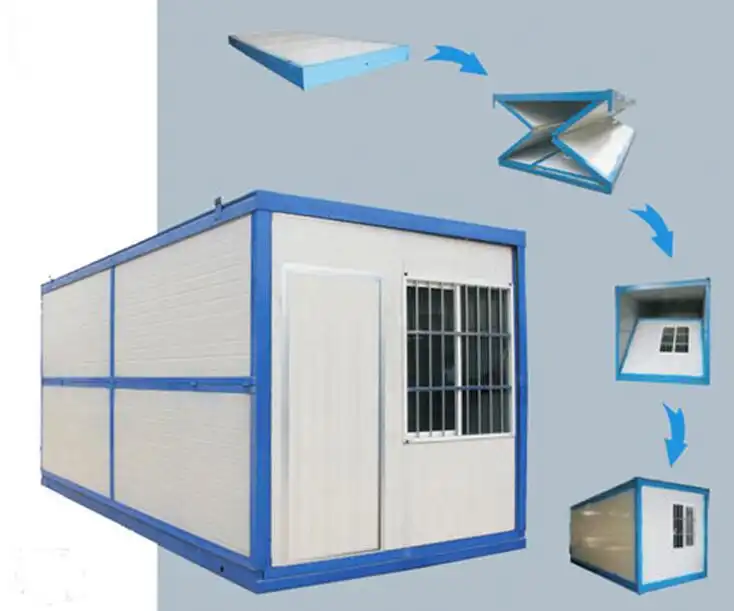

Warm cover boards offer exceptional flexibility in both measurements and applications, making them appropriate for a wide extend of development needs. These boards can be custom-made to meet particular venture determinations, guaranteeing ideal fit and execution. Ordinarily, outside boards are accessible in widths of 383mm, whereas insides boards come in 450mm widths. The thickness of insides boards is for the most part 10mm, while outside board thickness ranges from 16mm to 20mm. This adaptability permits for consistent integration over private, commercial, and mechanical building ventures.

This adaptability makes thermal insulation panels ideal for a diverse range of construction projects, including residential complexes, office buildings, private villas, landscaped garden structures, and municipal facilities. They are also widely used in the renovation of historic buildings and the construction of security kiosks. Architects and builders value these panels not only for their thermal efficiency and durability but also for their ability to complement creative, visually appealing designs.

Safety and Durability Features of Thermal Insulation Panels

Fire Resistance and Safety

Security is a vital concern in building materials, and warm cover boards address this with noteworthy fire-resistant properties. These boards regularly carry a fire-protection rating of B1 or B2, demonstrating their capacity to stand up to fire spread and contribute to the generally fire security of a structure. This non-flammable characteristic gives peace of intellect to building inhabitants and property proprietors alike.

Weather Resistance and Durability

Warm separator boards are fastidiously designed to persevere a wide extend of natural challenges, guaranteeing long-term execution and toughness. With an amazingly moo waterproof rate of 0.0008, they viably piece dampness penetration, shielding insides spaces from water harm, erosion, and shape development. Moreover, their solid wind resistance rating of 8.0 Kpa gives basic soundness, indeed in zones habitually uncovered to solid winds or extraordinary climate.

Corrosion Resistance and Longevity

The corrosion-free design of thermal insulation panels contributes significantly to their longevity. By resisting environmental degradation, these panels maintain their structural integrity and insulating properties over extended periods. This resilience not only ensures consistent performance but also reduces the need for frequent replacements or repairs, contributing to long-term cost savings.

Installation and Environmental Considerations

Streamlined Installation Process

One of the key advantages of thermal insulation panels is their simplified installation process. While professional consultation is recommended for optimal results, the general installation procedure is straightforward:

1. Preparation: Ensure the installation surface is clean, dry, and free of debris.

2. Layout Planning: Develop a layout plan according to the specific design requirements.

3. Cutting: Use appropriate tools to trim panels to the required dimensions.

4. Attachment: Secure panels using mechanical fasteners or adhesives as per project specifications.

5. Sealing: Apply sealant around edges to prevent moisture ingress and ensure a tight fit.

This efficient installation process contributes to faster construction timelines and reduced labor costs.

Eco-Friendly Aspects

In an era of increasing environmental awareness, thermal insulation panels are an ideal fit for green building initiatives. By drastically reducing the energy required for heating and cooling, they help lower carbon emissions throughout a building's life cycle. Additionally, many modern manufacturers prioritize eco-conscious materials and cleaner production methods, reinforcing the sustainable credentials of these high-performance insulation solutions.

Cost-Effectiveness and Long-Term Value

While the initial investment in thermal insulation panels may be higher compared to traditional insulation methods, their long-term value proposition is compelling. The superior insulation performance leads to substantial energy savings over time, offsetting the initial costs. Additionally, the durability and low maintenance requirements of these panels contribute to reduced lifecycle costs, making them a cost-effective solution for energy-efficient construction.

Conclusion

Thermal insulation panels represent a cutting-edge solution in building technology, offering a unique combination of energy efficiency, durability, safety, and design flexibility. As the construction industry continues to evolve towards more sustainable and high-performance buildings, these panels are poised to play an increasingly important role. For those interested in exploring the benefits of thermal insulation panels for their next construction project, we invite you to reach out to our team of experts at info@sdqsc.com for personalized guidance and solutions.