Unparalleled Insulation and Energy Efficiency

Thermal Insulation Excellence

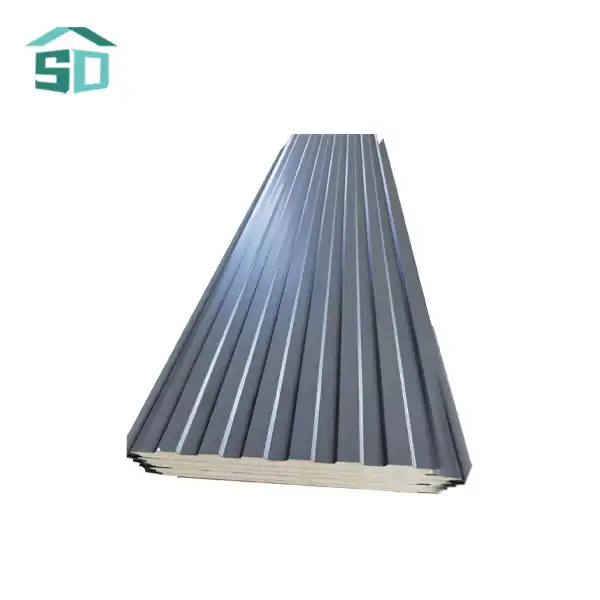

PU insulated sandwich panels are renowned for their exceptional thermal insulation properties. The polyurethane foam core acts as a formidable barrier against heat transfer, significantly reducing energy consumption for heating and cooling. This thermal efficiency translates to substantial cost savings for building owners and occupants. The panels' ability to maintain consistent indoor temperatures contributes to a more comfortable living or working environment, regardless of external weather conditions.

Acoustic Performance

Beyond thermal insulation, PU insulated sandwich panels also offer impressive acoustic insulation. The dense foam core effectively absorbs and dampens sound waves, reducing noise transmission between interior spaces and from the outside environment. This acoustic performance is particularly valuable in commercial and industrial settings where noise reduction is crucial for productivity and worker comfort. In residential applications, it ensures a quieter, more peaceful living space, shielding occupants from external disturbances.

Energy-Efficient Building Envelope

The combination of thermal and acoustic insulation properties makes PU insulated sandwich panels an integral component of energy-efficient building envelopes. By minimizing heat loss in winter and heat gain in summer, these panels contribute to reduced HVAC loads and lower energy bills. This energy efficiency aligns with modern sustainable building practices and can help projects achieve green building certifications. The long-term energy savings often offset the initial investment in PU insulated sandwich panels, making them a cost-effective choice for forward-thinking builders and property owners.

Durability and Structural Integrity

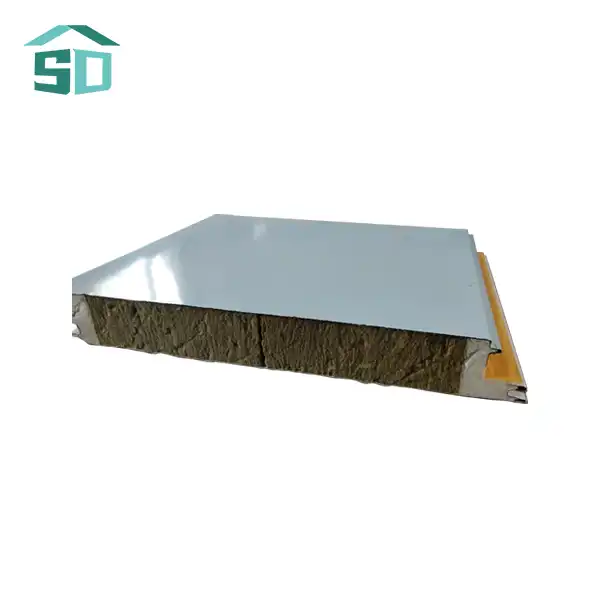

Weather Resistance

PU insulated sandwich panels are engineered to withstand a wide range of environmental challenges. The outer layers, typically made of steel or aluminum, provide robust protection against UV radiation, rain, snow, and wind. This weather resistance ensures the panels maintain their appearance and performance over time, even in harsh climates. The durability of these panels translates to reduced maintenance costs and longer building lifespans, making them an attractive option for both new construction and renovation projects.

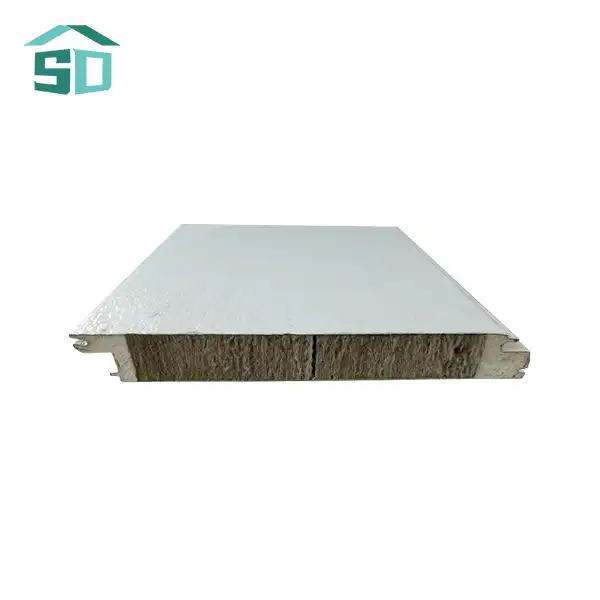

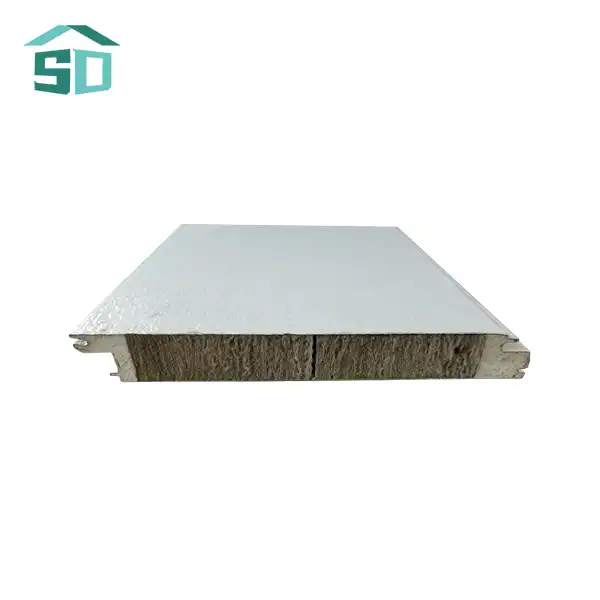

Structural Strength

Despite their lightweight nature, PU insulated sandwich panels offer impressive structural strength. The bond between the foam core and the outer layers creates a rigid, self-supporting panel that can span significant distances without additional support. This structural integrity allows for faster construction times and reduced framing requirements, potentially lowering overall project costs. The panels' strength-to-weight ratio makes them particularly suitable for large-scale industrial and commercial buildings where minimizing structural load is crucial.

Fire Resistance

Safety is paramount in building design, and PU insulated sandwich panels address this concern with inherent fire-resistant properties. Many modern PU foam formulations incorporate fire-retardant additives, significantly enhancing the panels' ability to resist flame spread and smoke development. This fire resistance contributes to overall building safety, potentially extending evacuation times in the event of a fire. It's important to note that specific fire ratings can vary depending on the panel composition and manufacturer, so builders should always verify compliance with local building codes and safety standards.

Versatility and Design Flexibility

Customization Options

PU insulated sandwich panels offer a wide range of customization options to meet diverse architectural and aesthetic requirements. These panels are available in various thicknesses, allowing designers to balance insulation needs with structural considerations. The outer layers can be finished in a multitude of colors, textures, and patterns, enabling seamless integration with different architectural styles. This design flexibility allows architects and builders to create visually appealing facades while maintaining the panels' functional benefits.

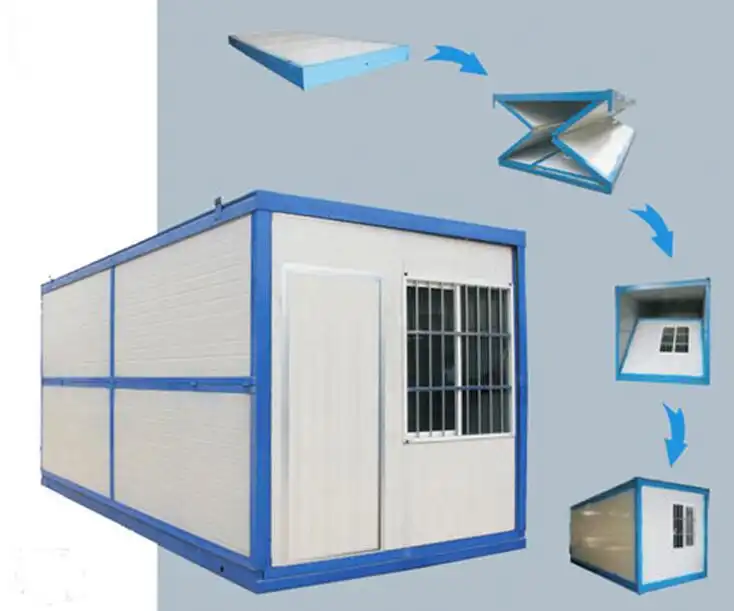

Easy Installation and Maintenance

One of the key advantages of PU insulated sandwich panels is their ease of installation. Manufactured in standardized sizes, these panels often feature interlocking systems that make assembly quick and straightforward. This streamlined installation process not only reduces on-site labor requirements but also helps to speed up project timelines significantly. Furthermore, the panels' smooth, durable surfaces are easy to clean and maintain, leading to lower long-term operational and maintenance costs, making them an ideal choice for cost-efficient construction.

Adaptability to Various Applications

The versatility of PU insulated sandwich panels extends to their wide range of applications. These panels are suitable for exterior walls, roofing systems, and interior partitions in various building types. From cold storage facilities and industrial warehouses to office buildings and residential complexes, PU insulated sandwich panels adapt to diverse architectural needs. Their ability to provide both structural and insulative functions in a single product makes them an efficient choice for many construction projects.

Conclusion

PU insulated sandwich panels offer a unique combination of properties that make them an invaluable asset in modern construction. Their exceptional insulation capabilities, durability, and design flexibility address many of the challenges faced by today's builders and architects. As the construction industry continues to prioritize energy efficiency and sustainable practices, the demand for high-performance materials like PU insulated sandwich panels is likely to grow.

For those interested in learning more about these innovative building solutions or exploring their potential for specific projects, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to provide detailed information and assist you in finding the ideal PU insulated sandwich panel solution for your construction needs.