The Pinnacle of Insulation: PU Insulated Sandwich Panels

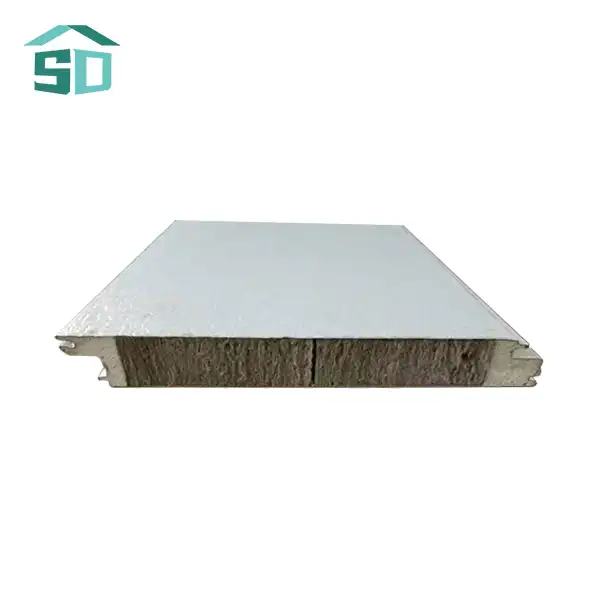

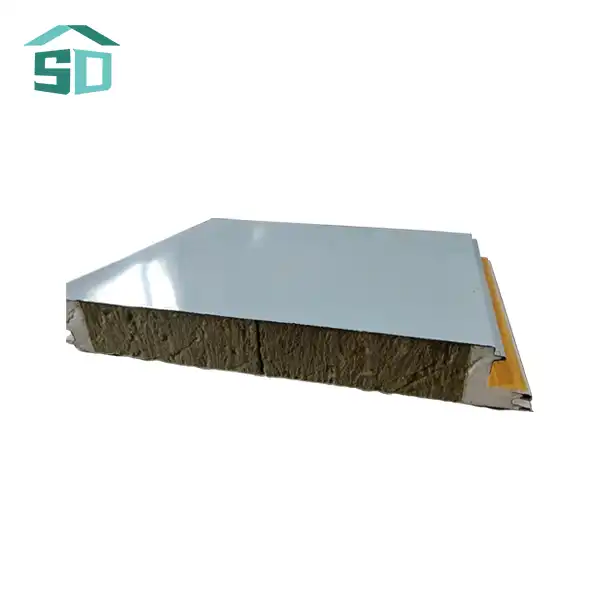

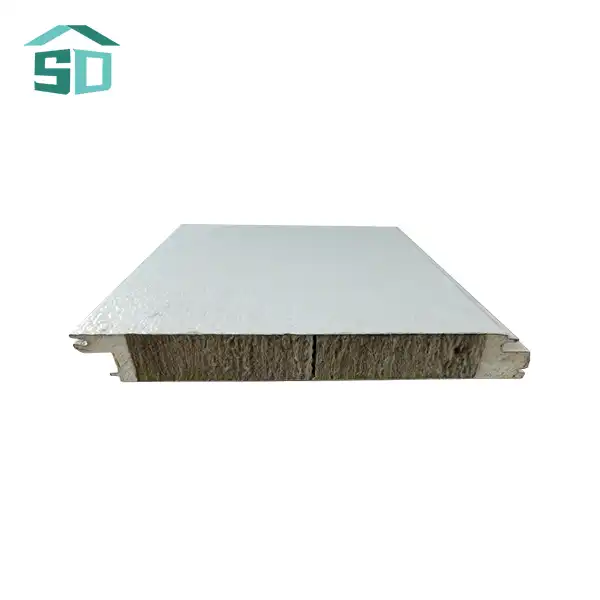

PU Insulated Sandwich Panels represent the cutting edge in building insulation technology. These advanced panels are meticulously engineered to deliver exceptional thermal performance, structural durability, and design flexibility. At their core lies high-density polyurethane foam, securely encased between two outer layers of robust metal or other compatible materials. This layered construction makes them an ideal solution for a wide range of construction applications, offering both energy efficiency and long-term reliability in one product.

Unmatched Thermal Performance

The polyurethane core used in PU Insulated Sandwich Panels features exceptionally low thermal conductivity, enabling it to provide outstanding insulation. This high-performance material helps retain heat during cold weather and reflects heat during warmer months, significantly stabilizing indoor temperatures. The result is a consistent reduction in the need for heating and cooling systems, leading to lower energy consumption, reduced utility bills, and a smaller environmental footprint over the lifespan of the building.

Structural Integrity and Longevity

Beyond their insulation capabilities, PU panels offer remarkable structural strength. The bonding between the core and the outer layers creates a robust composite material that can withstand various environmental stresses. This durability ensures that buildings constructed with these panels maintain their integrity and insulation properties for extended periods, reducing maintenance needs and replacement costs.

Versatility in Application

PU Insulated Sandwich Panels are incredibly versatile, suitable for walls, roofs, and even flooring in some applications. Their lightweight nature makes them easy to handle and install, reducing construction time and labor costs. Moreover, these panels can be customized in terms of thickness, facing materials, and finishes to meet specific project requirements and aesthetic preferences.

Flame-Retardant Properties and Safety Considerations

Safety is a critical concern in all construction projects, and PU Insulated Sandwich Panels are designed with this priority in mind. Thanks to modern manufacturing advancements, the flame-retardant capabilities of these panels have been greatly improved. These enhancements address earlier concerns about polyurethane's fire behavior, making the panels a much safer option for various building types.

Advanced Fire Resistance Technology

Today’s PU Insulated Sandwich Panels are equipped with advanced fire-resistant technologies, including specialized additives and innovative structural designs. These features effectively slow down flame spread and minimize smoke production during a fire. Additionally, the outer metal layers act as a physical barrier, offering extra protection for the insulation core and improving the overall fire performance of the panel system.

Compliance with Safety Standards

Leading manufacturers ensure that PU Insulated Sandwich Panels conform to or exceed established international fire safety regulations. Compliance with these standards is critical for construction approvals and safety certifications. This adherence gives confidence to stakeholders—architects, engineers, builders, and property owners—that the materials used promote a safer built environment and meet rigorous performance expectations.

Enhanced Occupant Safety

Improved fire resistance in PU Insulated Sandwich Panels significantly enhances the safety of building occupants. In the unfortunate event of a fire, the panels help contain the spread of flames, providing valuable time for evacuation. This additional time can be vital in preventing injuries and saving lives, making these panels a reliable component in fire-conscious building design.

Environmental Impact and Sustainability

As the construction industry moves towards more sustainable practices, the environmental impact of building materials is under increasing scrutiny. PU Insulated Sandwich Panels offer several advantages in this regard, aligning with green building initiatives and environmental conservation efforts.

Energy Efficiency and Carbon Footprint Reduction

The superior insulation properties of PU panels significantly reduce the energy required for heating and cooling buildings. This energy efficiency translates to lower greenhouse gas emissions over the lifespan of the structure, contributing to overall carbon footprint reduction.

Recyclability and Waste Reduction

Advancements in manufacturing and recycling technologies have improved the end-of-life options for PU panels. Many components can be recycled or repurposed, reducing waste and supporting circular economy principles. Additionally, the long lifespan of these panels means less frequent replacement, further minimizing waste generation.

Sustainable Manufacturing Practices

Leading manufacturers of PU Insulated Sandwich Panels are increasingly adopting sustainable production methods. This includes using recycled materials where possible, implementing energy-efficient manufacturing processes, and reducing harmful emissions during production.

Conclusion

PU Insulated Sandwich Panels represent a pinnacle in building insulation technology, offering a unique combination of thermal efficiency, structural integrity, and sustainability. Their versatility, coupled with advanced safety features and environmental benefits, makes them an excellent choice for a wide range of construction projects. As the industry continues to evolve, these panels are likely to play an increasingly important role in creating energy-efficient, safe, and sustainable buildings.

For more information about exterior cladding and facade solutions, including PU Insulated Sandwich Panels, please contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is committed to providing high-quality products and unparalleled service to enhance your construction projects.

References

1. Ashrae. (2017). ASHRAE Handbook—Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

2. Mohd, N. L., Sapian, A., & Mohd, S. (2018). Performance Evaluation of Polyurethane Sandwich Panels in Building Construction. Journal of Building Engineering, 19, 252–259.

3. Kim, H. J., & Lee, J. Y. (2020). Fire Resistance of Sandwich Panels with Polyurethane and Mineral Wool Cores. Construction and Building Materials, 239, 117837.

4. Papadopoulos, A. M. (2005). State of the Art in Thermal Insulation Materials and Aims for Future Developments. Energy and Buildings, 37(1), 77–86.

5. Zhou, X., & Zhao, Y. (2021). Environmental Impact and Recycling Potential of Rigid Polyurethane Foams in Construction Applications. Journal of Cleaner Production, 279, 123645.

6. Dombayci, O. A. (2007). Environmental Impact of Thermal Insulation Thickness in Buildings. Building and Environment, 42(10), 3855–3859.