The Science Behind UV-Resistant Foam Exterior Wall Cladding

Understanding UV Degradation and Its Effects on Building Materials

Ultraviolet (UV) radiation from the sun is a formidable adversary to many building materials. Over time, UV exposure can lead to color fading, material breakdown, and reduced structural integrity. Traditional cladding options often succumb to these effects, resulting in frequent replacements and increased maintenance costs. The development of UV-resistant foam exterior wall cladding addresses this challenge head-on, utilizing advanced polymer science to create a material that maintains its properties even under prolonged sun exposure.

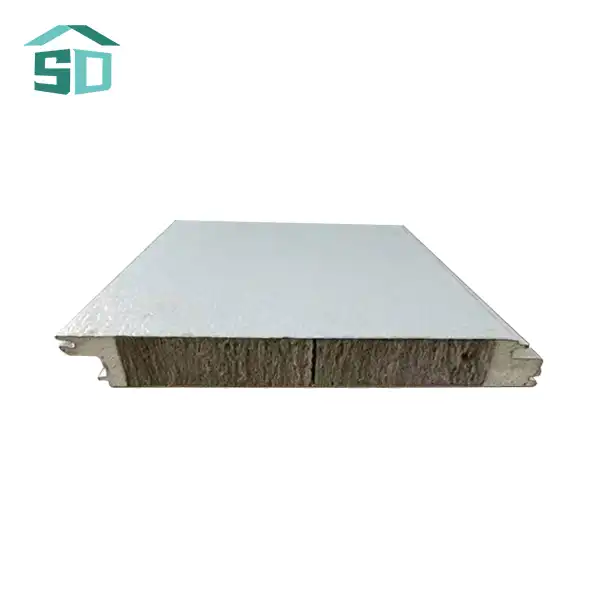

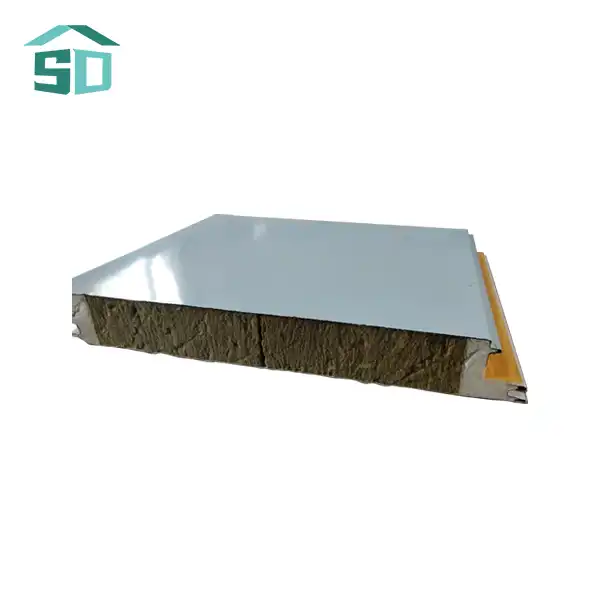

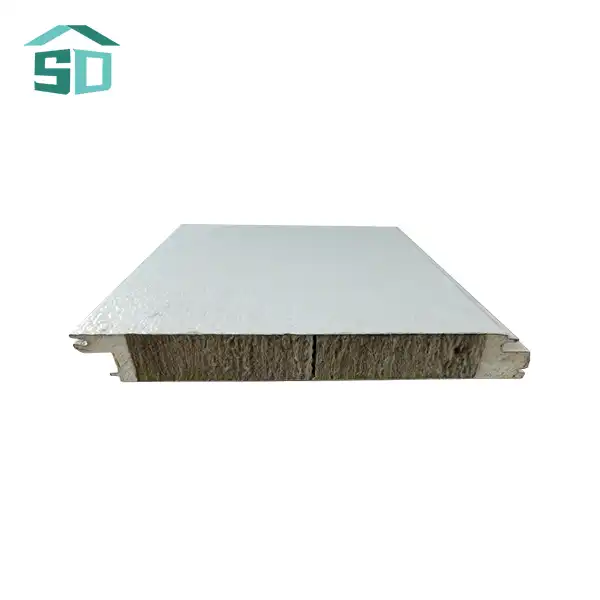

Composition of UV-Resistant Foam Panels

The core of UV-resistant foam panels is typically made from high-density polyurethane or similar foam materials. This core is then encapsulated with a UV-resistant outer layer, often composed of specially formulated resins or coatings. These protective layers incorporate UV stabilizers and absorbers that effectively shield the foam core from harmful radiation. The result is a cladding material that combines the insulative properties of foam with the durability of UV-resistant compounds.

Mechanisms of UV Protection in Foam Cladding

UV-resistant foam panels employ several mechanisms to combat sun damage. UV absorbers within the outer layer capture and dissipate harmful UV rays before they can penetrate the foam core. Additionally, antioxidants are incorporated to neutralize free radicals generated by UV exposure, preventing chain reactions that lead to material degradation. Some advanced formulations also include reflective particles that scatter UV radiation, further enhancing the panel's protective capabilities.

Benefits and Applications of UV-Resistant Foam Exterior Wall Cladding

Enhanced Durability and Longevity

One of the primary advantages of UV-resistant foam exterior wall cladding is its exceptional durability. These panels are engineered to withstand years of sun exposure without significant degradation in appearance or performance. This longevity translates to reduced maintenance requirements and lower long-term costs for building owners. The UV-resistant properties ensure that the cladding retains its color and structural integrity, maintaining the building's aesthetic appeal for extended periods.

Energy Efficiency and Insulation

Foam exterior wall cladding is renowned for its superior insulative properties, and UV-resistant variants are no exception. The foam core provides excellent thermal insulation, helping to maintain comfortable indoor temperatures while reducing heating and cooling costs. The UV-resistant outer layer adds an extra dimension to this efficiency by preventing heat absorption from solar radiation. This dual-action approach to energy management makes UV-resistant foam panels an ideal choice for environmentally conscious construction projects.

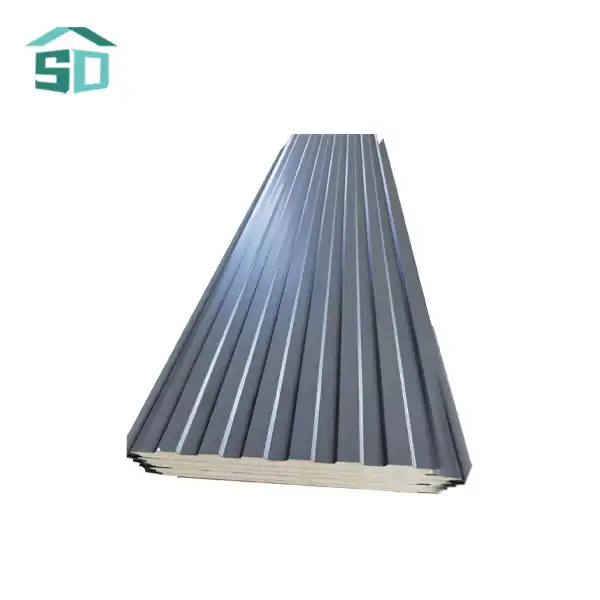

Versatility in Design and Application

UV-resistant foam panels offer architects and designers a wide range of creative possibilities. These panels can be manufactured in various colors, textures, and finishes, allowing for customization to suit diverse architectural styles. From sleek modern designs to more traditional aesthetics, foam exterior wall cladding can be adapted to complement any building facade. The lightweight nature of the panels also facilitates easier installation and opens up possibilities for unique architectural features that might be challenging with heavier cladding materials.

Installation and Maintenance of UV-Resistant Foam Panels

Best Practices for Installation

Proper installation is crucial for maximizing the benefits of UV-resistant foam exterior wall cladding. The process typically begins with ensuring a clean, dry substrate. Specialized adhesives and mechanical fasteners are used to secure the panels, with particular attention paid to creating proper seals at joints and edges. It's essential to follow manufacturer guidelines for spacing and expansion allowances, as foam panels can experience slight dimensional changes with temperature fluctuations. Professional installation is recommended to ensure optimal performance and longevity of the cladding system.

Maintenance Requirements and Recommendations

One of the significant advantages of UV-resistant foam panels is their low maintenance requirements. Regular cleaning with mild soap and water is usually sufficient to maintain their appearance. However, it's important to conduct periodic inspections to check for any damage or wear, particularly around seams and fastening points. Any identified issues should be addressed promptly to prevent moisture ingress or further damage. With proper care, UV-resistant foam exterior wall cladding can maintain its performance and aesthetic appeal for many years, making it a cost-effective choice for long-term building protection.

Long-Term Performance Expectations

When properly installed and maintained, UV-resistant foam panels can be expected to perform effectively for several decades. Many manufacturers offer warranties ranging from 20 to 50 years, depending on the specific product and application. Over time, some gradual color fading may occur, but this is typically minimal compared to non-UV-resistant alternatives. The insulative properties of the foam core remain stable over the long term, ensuring continued energy efficiency benefits throughout the lifespan of the cladding.

Conclusion

UV-resistant foam exterior wall cladding represents a significant advancement in building envelope technology. By combining the insulative properties of foam with robust UV protection, these panels offer a comprehensive solution for modern construction needs. From enhanced durability and energy efficiency to design versatility and low maintenance requirements, UV-resistant foam panels provide numerous benefits for both new constructions and renovation projects. As the demand for sustainable and long-lasting building materials continues to grow, UV-resistant foam cladding is poised to play an increasingly important role in shaping the future of architectural design and construction practices.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing cutting-edge solutions for your exterior cladding needs. Our UV-resistant foam panels are designed to deliver exceptional performance and lasting beauty. Interested in learning more about how our products can enhance your next project? Contact us at info@sdqsc.com to discuss your specific requirements and discover the perfect cladding solution for your building.

FAQs

How long do UV-resistant foam panels typically last?

With proper installation and maintenance, UV-resistant foam panels can last 20-50 years, depending on the specific product and environmental conditions.

Can UV-resistant foam exterior wall cladding be painted?

While it's possible to paint these panels, it's generally not recommended as it may affect their UV-resistant properties and void warranties. It's best to choose panels in your desired color during initial installation.

Are UV-resistant foam panels environmentally friendly?

Many manufacturers produce these panels using environmentally conscious methods and materials. They also contribute to energy efficiency, which can reduce a building's overall environmental impact.

How do UV-resistant foam panels compare to traditional cladding materials in terms of cost?

While initial costs may be higher than some traditional materials, the long-term savings in energy efficiency and reduced maintenance often make UV-resistant foam panels a cost-effective choice over time.

References

1.Asdrubali, F., D'Alessandro, F., & Schiavoni, S. (2015). A review of unconventional sustainable building insulation materials. Sustainable Materials and Technologies, 4, 1-17.

2.Jelle, B. P. (2011). Traditional, state-of-the-art and future thermal building insulation materials and solutions – Properties, requirements and possibilities. Energy and Buildings, 43(10), 2549-2563.

3.Maury-Ramirez, A., & De Belie, N. (2010). State of the art of TiO2 containing cementitious materials: self-cleaning properties. Materiales de Construcción, 60(298), 33-50.

4.Nguyen, T., Pellegrin, B., Bernard, C., Gu, X., Gorham, J. M., Stutzman, P., ... & Chin, J. W. (2011). Fate of nanoparticles during life cycle of polymer nanocomposites. Journal of Physics: Conference Series, 304(1), 012060.

5.Pacheco-Torgal, F., Diamanti, M. V., Nazari, A., & Granqvist, C. G. (Eds.). (2018). Nanotechnology in eco-efficient construction: Materials, processes and applications. Woodhead Publishing.