Unparalleled Performance and Durability

Robust Construction for Long-Lasting Strength

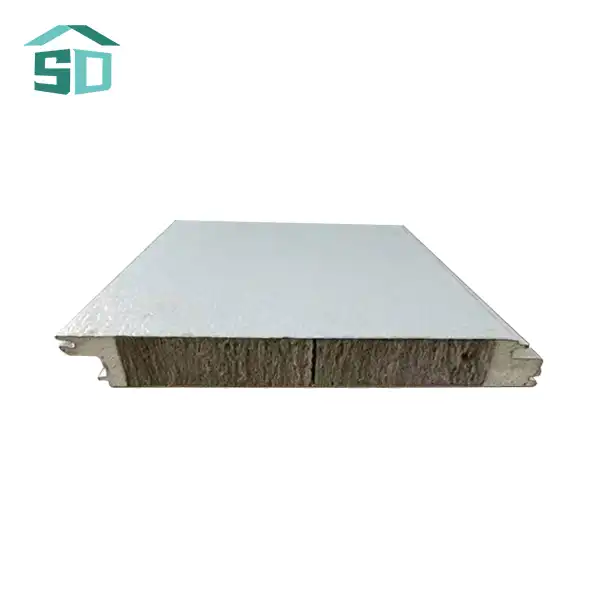

Metal insulated sandwich panels are engineered to withstand the test of time. The outer layers, typically made of steel or aluminum, provide exceptional strength and resistance to external forces. With a thickness ranging from 0.23mm to 0.27mm, these surface materials ensure the panels can endure various environmental stressors without compromising their structural integrity. The robust construction translates to reduced maintenance costs and extended building lifespans, making these panels a wise investment for any construction project.

Superior Weather Resistance

One of the standout features of metal insulated sandwich panels is their remarkable ability to resist adverse weather conditions. These panels boast an impressive waterproof rate of 0.0008, effectively preventing moisture penetration and protecting the building's interior from water damage. Moreover, their wind resistance capability of 8.0 Kpa ensures that they can withstand high-speed winds, making them suitable for use in areas prone to severe weather events. This level of weather resistance not only protects the building but also contributes to its overall longevity and reduced maintenance requirements.

Corrosion-Proof Design for Longevity

The corrosion-proof plan of metal protects sandwich boards is a significant figure in their long-term execution. These boards are treated with specialized coatings that secure against rust and weathering, guaranteeing they keep up their appearance and usefulness indeed in unforgiving situations. This resistance to erosion is especially useful in coastal regions or mechanical settings where presentation to destructive components is tall, making these boards a solid choice for a wide run of applications.

Energy Efficiency and Thermal Performance

Exceptional Insulation Properties

At the center of metal protects sandwich boards lies their remarkable cover capabilities. These boards regularly highlight a polyurethane (PU) or polyisocyanurate (PIR) center, which gives predominant warm cover. With a warm conductivity of fair 0.018W/m.k, these boards essentially decrease warm exchange between the insides and outside of a building. This moo warm conductivity deciphers to improved vitality productivity, making a difference keep up comfortable indoor temperatures year-round whereas decreasing the stack on HVAC frameworks.

Impressive Thermal Resistance

The thermal resistance of metal insulated sandwich panels is a key factor in their energy-saving capabilities. With a thermal resistance value of 2.09m2k/w, these panels effectively minimize heat flow through the building envelope. This high level of thermal resistance contributes to a more stable indoor environment, reducing temperature fluctuations and enhancing overall comfort for occupants. The result is not only improved living or working conditions but also significant energy savings over the life of the building.

Customizable Thickness for Optimal Performance

Metal insulated sandwich panels offer flexibility in terms of thickness, allowing for customization based on specific project requirements. Interior panels typically have a thickness of 10mm, while exterior panels range from 16mm to 20mm. This adaptability enables architects and builders to optimize the insulation performance for different areas of a building, ensuring that each space receives the appropriate level of thermal protection. The ability to tailor panel thickness contributes to more efficient building designs and improved overall energy performance.

Versatility in Design and Application

Aesthetic Flexibility for Creative Expression

One of the most compelling aspects of metal insulated sandwich panels is their aesthetic versatility. These panels are available in a wide range of colors and patterns, allowing architects and designers to unleash their creativity and achieve unique visual effects. Whether the goal is to create a sleek, modern facade or to complement a traditional architectural style, metal insulated sandwich panels can be customized to meet diverse aesthetic requirements. This flexibility in design makes them suitable for various projects, from residential complexes and offices to municipal buildings and historic renovations.

Adaptable Dimensions for Various Applications

Metal insulated sandwich panels come in different widths to suit various applications. Exterior panels typically have a width of 383mm, while interior panels are wider at 450mm. This range of dimensions allows for efficient installation and enables the panels to be used in different parts of a building structure. The adaptability in size, combined with customizable lengths, makes these panels a versatile solution for both interior and exterior wall finishes, contributing to streamlined construction processes and reduced material waste.

Fire Safety and Building Code Compliance

Security is fundamental in any development venture, and metal protects sandwich boards exceed expectations in this viewpoint. These boards are certified with fire-protection appraisals of B1/B2, showing their non-combustible nature and capacity to stand up to fire spread. This tall level of fire security not as it were secures inhabitants and resources but too guarantees compliance with rigid building codes and directions. The fire-resistant properties of these boards make them an perfect choice for a wide extend of building sorts, counting those with strict security prerequisites.

Conclusion

Metal insulated sandwich panels offer a comprehensive solution for modern construction needs, combining durability, energy efficiency, and design flexibility. Their superior performance in terms of insulation, weather resistance, and fire safety, coupled with their aesthetic versatility, makes them an excellent choice for various building applications. As the construction industry continues to evolve towards more sustainable and efficient practices, metal insulated sandwich panels stand out as a forward-thinking solution that meets both current and future building requirements. For more information on how these innovative panels can enhance your next construction project, feel free to contact us at info@sdqsc.com.