Unparalleled Durability and Insulation Performance

Metal Construction: The Foundation of Longevity

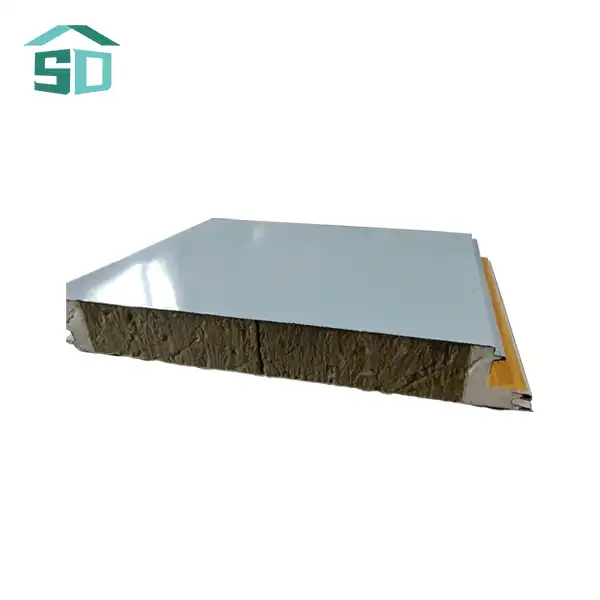

The backbone of substance-insulated sandwich panels lies in their robust substance construction. This fundamental point ensures unrivaled durability and strength, setting these panels piecemeal from traditional structure paraphernalia. The substance face not only provides structural integrity but also acts as a protective guard against external rudiments. With a viscosity of face paraphernalia ranging from 0.23 mm to 0.27 mm, these panels are finagled to repel the test of time and environmental challenges.

The metal construction contributes significantly to the panel's impressive wind resistance of 8.0 Kpa. This remarkable resistance enables the panels to maintain their structural integrity even in high-wind conditions, making them an excellent choice for buildings in areas prone to severe weather. The metal's inherent strength also translates to a high compressive strength of 52.7kpa, ensuring that the panels can bear substantial loads without compromising their performance or appearance.

Efficient Insulation: The Core of Comfort

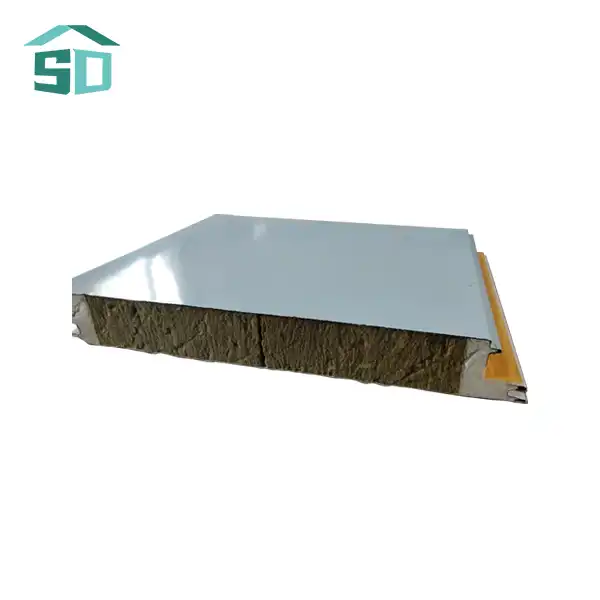

At the heart of metal insulated sandwich panels lies their exceptional insulation properties. The panels feature a PU/PIR (Polyurethane/Polyisocyanurate) core, which is renowned for its superior insulation capabilities. This core is the key to maintaining ideal temperatures within buildings, regardless of external weather conditions.

The thermal conductivity of these panels is an impressive 0.018W/m.k, indicating their ability to minimize heat transfer effectively. This low thermal conductivity translates to a high thermal resistance of 2.09m2k/w, ensuring that the interior spaces remain comfortable year-round while reducing the energy demands for heating and cooling. The efficiency of this insulation not only enhances occupant comfort but also contributes significantly to the energy efficiency of the building, potentially leading to substantial cost savings over time.

Safety and Resilience in Extreme Conditions

Fire Safety: A Non-Negotiable Feature

In the realm of construction materials, fire safety is paramount. Metal insulated sandwich panels excel in this aspect, boasting a fire-protection rating of B1/B2. This certification ensures that the panels are non-combustible, significantly reducing the risk of fire spread in the event of an emergency. The fire-resistant properties of these panels provide an additional layer of safety for building occupants and help in meeting stringent building safety codes and regulations.

The fire safety features of these panels are not just about meeting regulatory requirements; they offer peace of mind to building owners and occupants alike. In commercial and industrial settings, where fire hazards can be more prevalent, the use of these fire-resistant panels can be a crucial factor in risk mitigation and insurance considerations.

Corrosion-Proof Design: Weathering the Elements

One of the standout features of metal insulated sandwich panels is their corrosion-proof design. This characteristic is vital for maintaining the structural integrity and appearance of the panels over extended periods, especially in harsh environmental conditions. The panels are engineered to resist rust and weathering, ensuring that they retain their functionality and aesthetic appeal despite exposure to various weather elements.

The corrosion resistance is complemented by an impressive waterproof rate of 0.0008. This near-impermeable barrier against water ingress not only protects the internal insulation core but also prevents moisture-related issues such as mold growth and structural damage. The combination of corrosion resistance and waterproofing makes these panels an ideal choice for both exterior and interior applications, particularly in regions with high humidity or frequent precipitation.

Versatility and Aesthetic Appeal in Construction

Customizable Aesthetics: Blending Form with Function

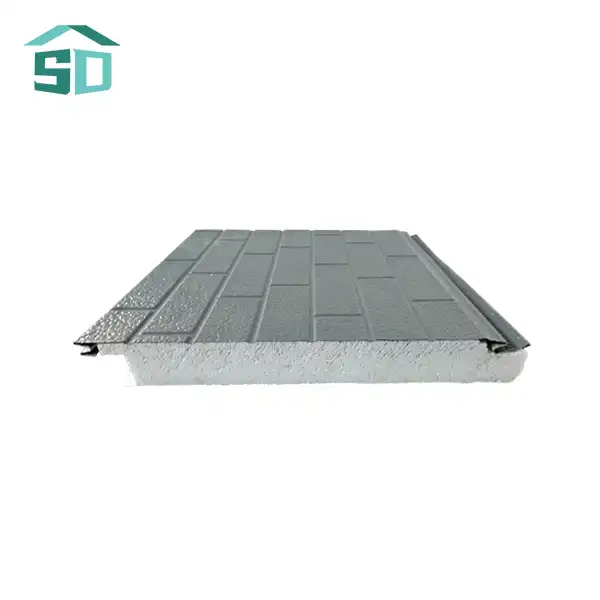

Metal insulated sandwich panels offer a remarkable range of customization options, allowing architects and designers to achieve their desired aesthetic vision without compromising on performance. These panels are available in a diverse array of colors and patterns, enabling them to complement or enhance any architectural style. This versatility in appearance makes them suitable for various applications, from sleek, modern office buildings to more traditional residential structures.

The customization extends beyond just color choices. The panels can be manufactured in different textures and finishes, providing additional design flexibility. This adaptability allows for creative expression in building facades, helping to create distinctive and attractive exteriors that can significantly enhance the overall appeal and value of a property.

Versatile Application: From Exteriors to Interiors

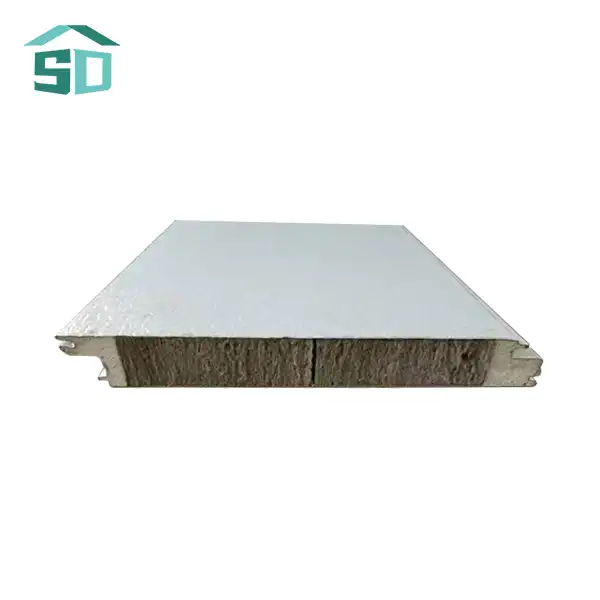

The versatility of metal insulated sandwich panels is further exemplified by their suitability for both exterior and interior applications. For exterior use, these panels are available in thicknesses of 16mm or 20mm, with a width of 383mm. This configuration makes them ideal for creating robust, well-insulated building envelopes. The exterior application of these panels not only provides thermal insulation but also contributes to the structural integrity and weather resistance of the building.

Interior applications are equally well-served by these panels, with a thickness of 10mm and a width of 450mm. This interior configuration allows for efficient space utilization while maintaining excellent insulation properties. The use of these panels in interior spaces can contribute to improved acoustic performance, creating more comfortable and functional indoor environments. Whether used for partition walls, ceiling systems, or interior cladding, these panels offer a clean, modern look coupled with practical benefits.

Conclusion

Metal insulated sandwich panels represent a pinnacle of modern construction materials, offering a harmonious blend of durability, insulation, safety, and aesthetic versatility. Their comprehensive range of features makes them an invaluable asset in various construction projects, from residential complexes to commercial buildings. As the construction industry continues to evolve towards more efficient and sustainable practices, these panels stand out as a solution that meets both current needs and future challenges. For those interested in exploring the possibilities of metal insulated sandwich panels for their construction projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, please contact us at info@sdqsc.com.