- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Benefits of Polyurethane Foam Sandwich Panels

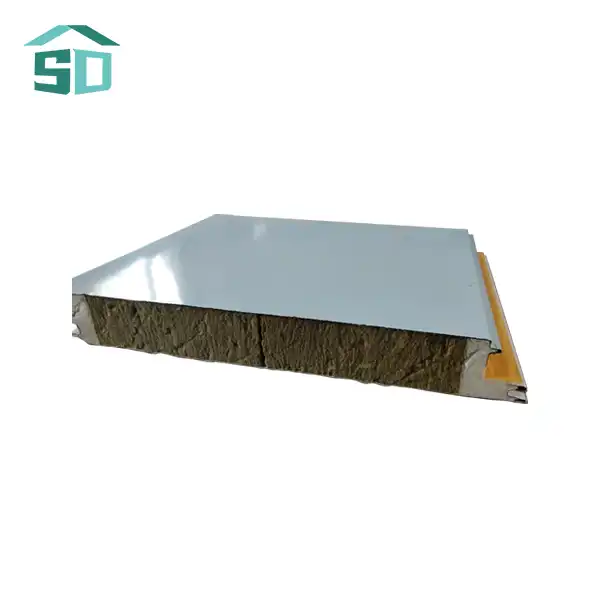

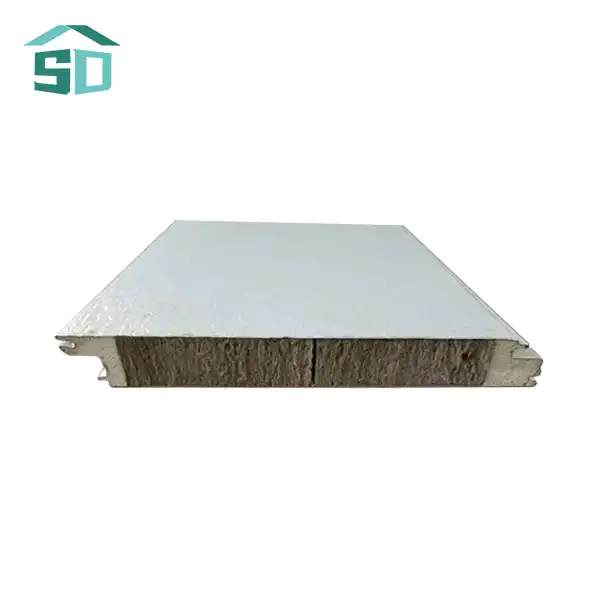

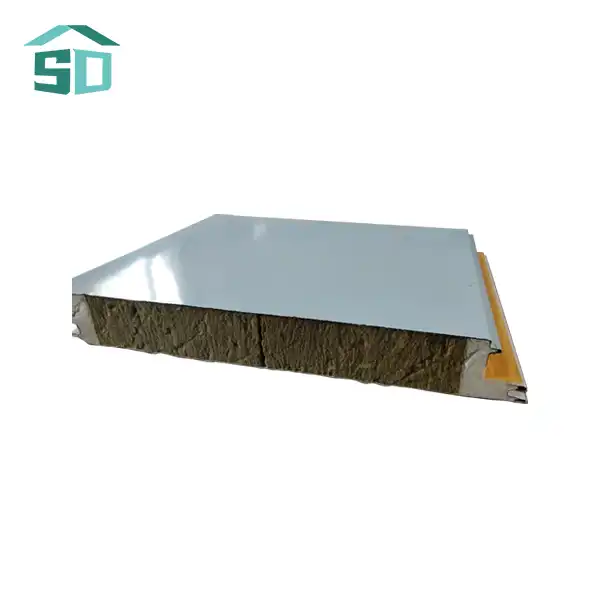

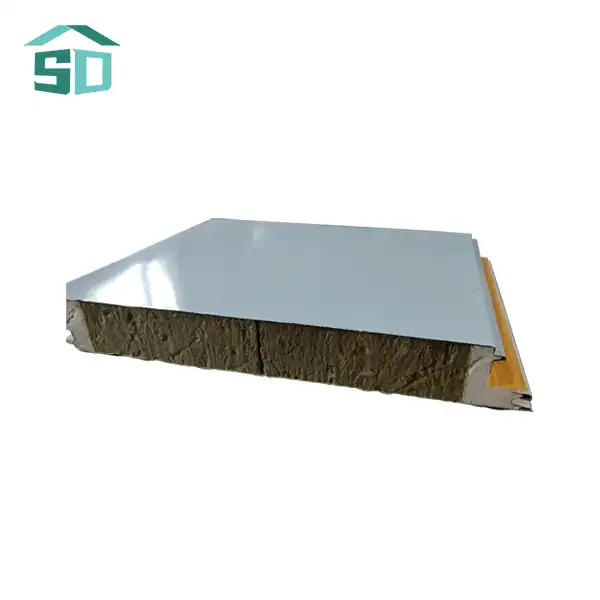

Polyurethane foam sandwich panels have emerged as a revolutionary solution in the construction industry, offering a myriad of benefits that make them an indispensable choice for both residential and commercial projects. These innovative panels combine exceptional thermal insulation, fire resistance, customizable aesthetics, and durability, making them a versatile option for wall decoration and insulation. With their energy-efficient properties and cost-saving potential, polyurethane foam sandwich panels are transforming the way we approach building design and construction, providing a perfect balance of functionality and style.

Unparalleled Insulation and Energy Efficiency

Exceptional Thermal Performance

Polyurethane foam sandwich panels are renowned for their superior thermal insulation properties. The core of these panels is composed of high-density polyurethane foam, which boasts an impressive R-value – a measure of thermal resistance. This exceptional insulation capacity ensures that buildings maintain a comfortable interior temperature regardless of external conditions, reducing the need for excessive heating or cooling.

The unique cellular structure of polyurethane foam creates countless tiny air pockets that effectively trap heat, minimizing thermal bridging and heat transfer. This results in a significant reduction in energy consumption, as HVAC systems don't need to work as hard to maintain desired temperatures. In fact, studies have shown that buildings utilizing polyurethane foam sandwich panels can achieve energy savings of up to 30% compared to traditional insulation materials.

Year-Round Comfort and Climate Control

The outstanding insulation properties of polyurethane foam sandwich panels contribute to a more stable and comfortable indoor environment throughout the year. During summer months, these panels help keep interiors cool by reflecting solar radiation and preventing heat infiltration. In winter, they retain warmth inside the building, reducing heat loss and eliminating cold spots.

This consistent climate control not only enhances occupant comfort but also plays a crucial role in protecting sensitive equipment and materials from temperature fluctuations. For industries such as pharmaceuticals, food storage, and data centers, where maintaining precise environmental conditions is critical, polyurethane foam sandwich panels offer an ideal solution.

Durability and Long-Term Cost Savings

Corrosion-Resistant and Weather-Proof

One of the standout features of polyurethane foam sandwich panels is their exceptional durability and resistance to environmental factors. These panels are engineered to withstand harsh weather conditions, including extreme temperatures, high humidity, and UV radiation. The outer layers of the panels are typically made from corrosion-resistant materials such as galvanized steel or aluminum, providing an additional layer of protection against the elements.

This resilience translates to a longer lifespan for the building envelope, reducing the need for frequent repairs or replacements. The corrosion-free nature of polyurethane foam sandwich panels ensures that they maintain their structural integrity and appearance over time, even in coastal or industrial areas where corrosive elements are prevalent.

Reduced Maintenance and Replacement Costs

The durability of polyurethane foam sandwich panels leads to significant long-term cost savings for building owners and managers. Unlike traditional building materials that may require regular maintenance, repainting, or replacement, these panels remain virtually maintenance-free for years. Their resistance to mold, mildew, and pests further reduces the need for costly treatments or repairs.

Moreover, the energy efficiency provided by these panels contributes to ongoing cost savings through reduced utility bills. The initial investment in polyurethane foam sandwich panels often pays for itself within a few years through lower energy consumption and minimal maintenance requirements, making them a cost-effective choice for sustainable building design.

Versatility and Aesthetic Appeal

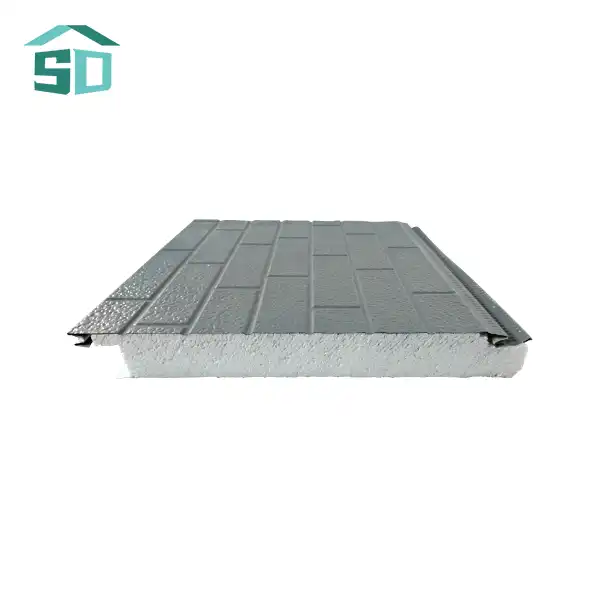

Customizable Design Options

Polyurethane foam sandwich panels offer unparalleled versatility in terms of design and aesthetics. These panels can be customized to suit a wide range of architectural styles and preferences, making them an attractive option for both new construction and renovation projects. Manufacturers like Weifang Sandong Building Materials Co., Ltd. offer an extensive selection of colors, textures, and patterns, allowing architects and designers to create unique and visually striking facades.

The panels can be fabricated to mimic the appearance of traditional building materials such as wood, brick, or stone, providing the aesthetic appeal of these materials without their associated maintenance challenges. This versatility enables designers to achieve their desired look while still benefiting from the superior performance of polyurethane foam sandwich panels.

Seamless Integration with Modern Architecture

The sleek, modern appearance of polyurethane foam sandwich panels makes them an ideal choice for contemporary architectural designs. Their clean lines and uniform surfaces create a polished, professional look that complements a wide range of building styles. The panels can be easily integrated with other building elements such as windows, doors, and architectural features, allowing for seamless and cohesive designs.

Furthermore, the lightweight nature of these panels offers greater flexibility in building design and construction. Architects can create bold, innovative structures that would be difficult or impossible to achieve with traditional building materials. This combination of aesthetic appeal and structural versatility has made polyurethane foam sandwich panels a favorite among architects and builders seeking to push the boundaries of modern design.

Adaptability for Various Applications

Polyurethane foam sandwich panels are not limited to exterior wall cladding; they find applications in numerous areas of construction. These versatile panels can be used for interior partitions, ceilings, roofing, and even flooring systems. Their adaptability makes them suitable for a wide range of building types, including residential complexes, commercial offices, industrial facilities, and specialized structures like cold storage units.

The panels' compatibility with various construction methods and their ease of installation further enhance their versatility. Whether used in new construction or retrofit projects, polyurethane foam sandwich panels can be seamlessly integrated into existing structures, providing an efficient solution for improving building performance and aesthetics.

Conclusion

In conclusion, polyurethane foam sandwich panels offer a comprehensive package of benefits that address the key challenges faced by modern construction projects. From exceptional thermal insulation and energy efficiency to durability, cost-effectiveness, and design versatility, these panels provide a superior alternative to traditional building materials.

As the construction industry continues to evolve towards more sustainable and efficient practices, polyurethane foam sandwich panels are poised to play an increasingly important role in shaping the buildings of the future. For more information on how these innovative panels can benefit your next project, contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com.

References

1. Polyurethane Manufacturers Association. (2021). Benefits of Polyurethane Foam Insulation.

2. Journal of Building Engineering. (2020). Thermal performance of polyurethane foam sandwich panels in building envelopes.

3. Construction and Building Materials. (2019). Durability and long-term performance of polyurethane foam sandwich panels in construction.

4. Architectural Review. (2022). Innovative Materials in Modern Architecture: The Rise of Polyurethane Foam Sandwich Panels.

5. Energy and Buildings. (2021). Energy efficiency improvements in buildings using polyurethane foam insulation systems.