- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Role of Prefabricated Thermal Panels in Acoustic Performance

Prefabricated thermal panels play a crucial role in enhancing acoustic performance in modern construction. These innovative building materials offer a dual benefit of thermal insulation and sound control, making them an indispensable component in creating comfortable and quiet environments. By incorporating sound-absorbing materials within their layered structure, prefabricated thermal panels effectively reduce noise transmission between spaces. This acoustic insulation property, combined with their thermal efficiency, makes them an ideal solution for various applications, from residential buildings to commercial spaces and industrial facilities.

Grasping Acoustic Properties of Prefabricated Thermal Panels

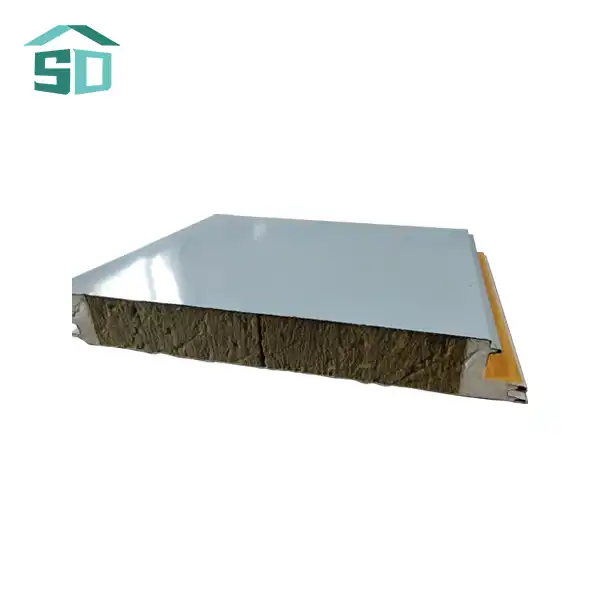

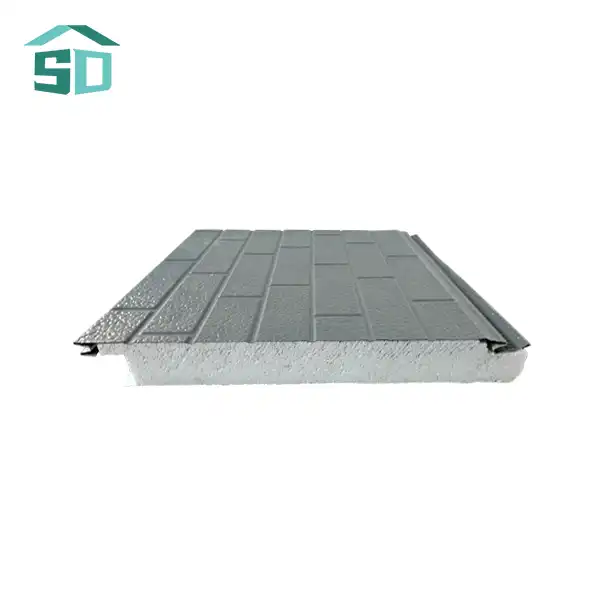

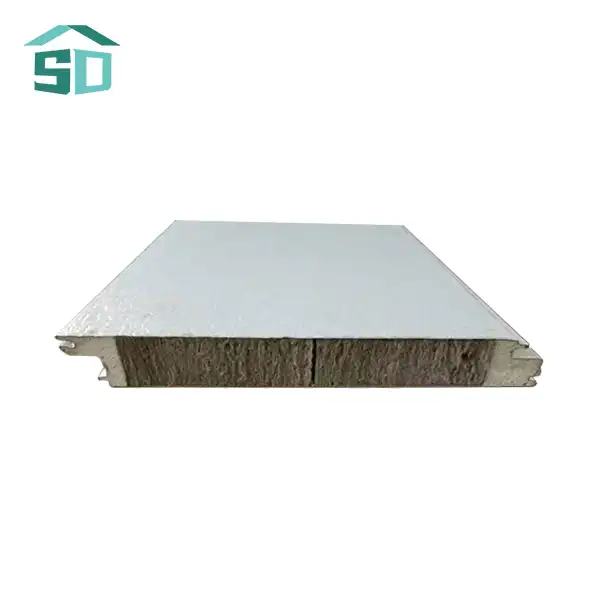

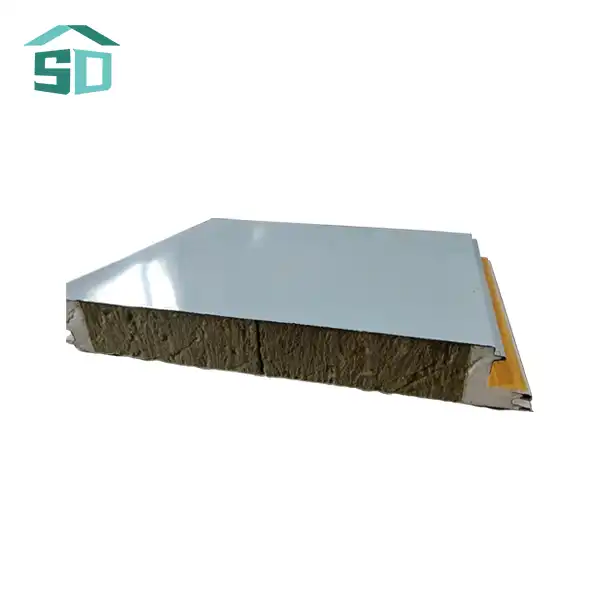

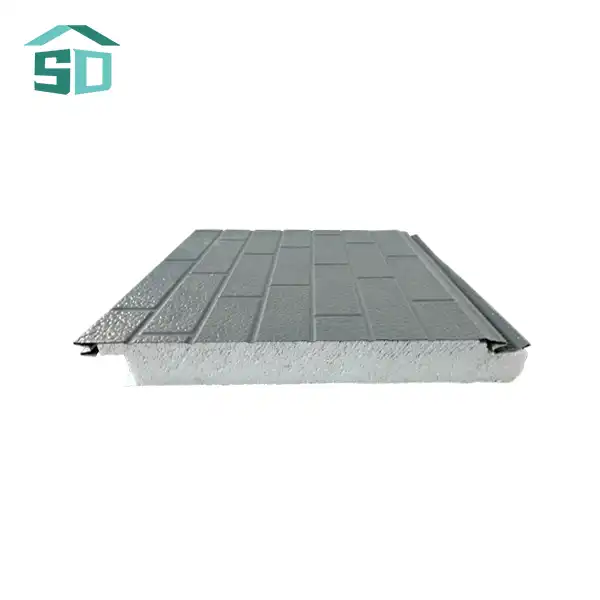

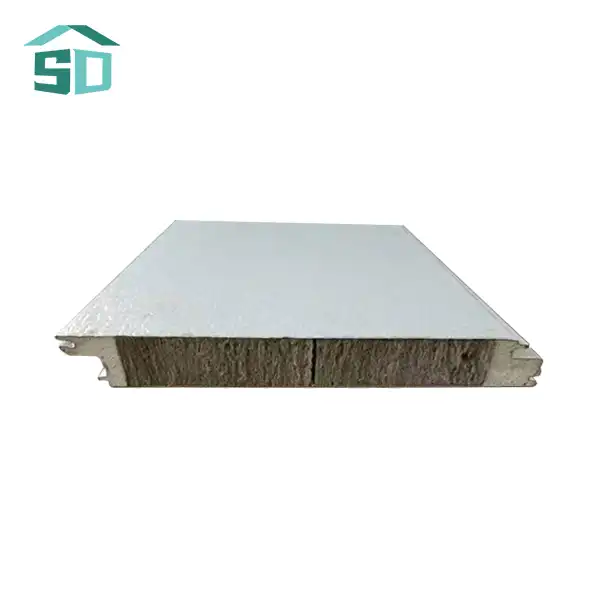

Composition and Structure

Prefabricated thermal panels are engineered with multiple layers, each serving a specific purpose. The core of these panels typically consists of insulating materials such as polyurethane, polystyrene, rock wool, or glass wool. These materials not only provide excellent thermal insulation but also contribute significantly to sound absorption and attenuation.

The outer layers of prefabricated thermal panels are usually made of durable materials like aluminum, steel, or stainless steel. These external layers add to the panel's structural integrity and provide a barrier against external noise. The combination of a dense outer layer and a sound-absorbing core creates an effective system for managing acoustic energy.

Sound Transmission Class (STC) Ratings

The acoustic performance of prefabricated thermal panels is often measured using the Sound Transmission Class (STC) rating. This rating indicates how well a building partition attenuates airborne sound. Higher STC ratings signify better sound insulation properties.

Prefabricated thermal panels can achieve impressive STC ratings, often ranging from 30 to 50 or higher, depending on their composition and thickness. For instance, a panel with an STC rating of 50 can significantly reduce loud speech to a faint murmur when heard through the wall. This level of sound insulation is particularly valuable in multi-unit residential buildings, hotels, or office spaces where privacy and noise reduction are paramount.

Frequency-Dependent Performance

It's important to note that the acoustic performance of prefabricated thermal panels can vary across different frequencies. Generally, these panels are more effective at blocking mid to high-frequency sounds, which include most human speech and many common household noises. Low-frequency sounds, such as bass from music or traffic rumble, may require additional measures for optimal control.

Benefits of Using Prefabricated Thermal Panels for Acoustic Control

Enhanced Indoor Comfort

By incorporating prefabricated thermal panels into building design, architects and builders can significantly enhance indoor comfort. These panels create a more peaceful environment by reducing external noise infiltration and minimizing sound transmission between rooms or floors. This acoustic benefit is particularly valuable in urban areas where exterior noise pollution can be a significant concern.

Moreover, the thermal insulation properties of these panels contribute to maintaining stable indoor temperatures, further enhancing overall comfort. The synergy between acoustic and thermal performance makes prefabricated thermal panels a comprehensive solution for creating pleasant indoor environments.

Energy Efficiency

While the primary focus of this article is on acoustic performance, it's worth noting that the thermal insulation provided by these panels also contributes to energy efficiency. By reducing heat transfer between the interior and exterior of a building, prefabricated thermal panels help maintain desired indoor temperatures with less reliance on heating and cooling systems. This dual functionality—acousticand thermal insulation—makes these panels a cost-effective solution for building envelopes.

Versatility in Application

Prefabricated thermal panels offer remarkable versatility in their application. They can be used in various construction projects, including:

- Residential buildings: Improving sound insulation between apartments or from external sources

- Commercial spaces: Creating quiet work environments in offices or meeting rooms

- Educational facilities: Enhancing concentration in classrooms by reducing external distractions

- Healthcare facilities: Ensuring patient privacy and comfort in hospitals and clinics

- Industrial settings: Controlling noise in manufacturing plants or warehouses

The adaptability of these panels allows architects and builders to address acoustic challenges across a wide range of building types and environments.

Installation and Integration of Prefabricated Thermal Panels for Optimal Acoustic Performance

Proper Installation Techniques

To maximize the acoustic benefits of prefabricated thermal panels, proper installation is crucial. The installation process typically involves:

- Surface preparation: Ensuring the substrate is clean, dry, and structurally sound

- Panel placement: Accurately positioning panels according to design specifications

- Sealing: Using appropriate sealants or adhesives to secure panels and maintain airtightness

- Joint treatment: Properly addressing panel joints to prevent sound leaks

Professional installation is recommended to ensure that the panels perform to their full potential in terms of both acoustic and thermal insulation.

Integration with Other Acoustic Solutions

While prefabricated thermal panels offer significant acoustic benefits on their own, they can be integrated with other sound control measures for even better performance. This may include:

- Incorporating additional sound-absorbing materials in wall cavities

- Using acoustic sealants at panel joints and penetrations

- Combining panels with suspended ceilings or floating floors for enhanced sound isolation

- Implementing active noise control systems in particularly challenging acoustic environments

By considering prefabricated thermal panels as part of a comprehensive acoustic design strategy, builders can achieve superior sound control in various architectural contexts.

Customization and Aesthetic Considerations

One of the advantages of prefabricated thermal panels is their customizability. Manufacturers like Weifang Sandong Building Materials Co., Ltd. offer these panels in various colors, finishes, and textures. This allows architects to integrate acoustic solutions seamlessly into their design vision without compromising aesthetics.

The ability to customize panel appearance ensures that acoustic performance doesn't come at the expense of visual appeal. Whether the project calls for a sleek, modern look or a more traditional aesthetic, prefabricated thermal panels can be tailored to meet both acoustic and design requirements.

Conclusion

Prefabricated thermal panels have emerged as a versatile and effective solution for enhancing acoustic performance in modern construction. Their ability to combine sound insulation with thermal efficiency makes them an invaluable asset in creating comfortable, quiet, and energy-efficient spaces.

From residential buildings to commercial and industrial applications, these panels offer a range of benefits that contribute to improved indoor environmental quality. As the demand for sustainable and high-performance buildings continues to grow, the role of prefabricated thermal panels in acoustic design is likely to become even more significant.

Their adaptability, customization options, and ease of installation make them an attractive choice for architects, builders, and property owners alike. Ready to elevate your building's acoustic performance with our state-of-the-art prefabricated thermal panels? Contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com to explore our customized solutions and take the first step towards creating quieter, more comfortable spaces.

FAQs

What are the primary benefits of using prefabricated thermal panels for acoustic control?

Prefabricated thermal panels offer the dual benefits of sound insulation and thermal efficiency, enhancing indoor comfort and energy savings.

How do prefabricated thermal panels compare to traditional insulation methods in terms of acoustic performance?

These panels often outperform traditional methods due to their engineered, multi-layered structure that effectively absorbs and blocks sound.

Can prefabricated thermal panels be used in renovation projects?

Yes, they are suitable for both new construction and renovation projects, offering a relatively easy-to-install solution for improving acoustic performance.

What factors should be considered when selecting prefabricated thermal panels for acoustic purposes?

Consider the panel's STC rating, thickness, core material, and compatibility with the existing structure and design requirements.

Are there any maintenance requirements for prefabricated thermal panels to maintain their acoustic performance?

Generally, these panels require minimal maintenance. Regular inspections to ensure panel integrity and proper sealing can help maintain optimal performance.

References

1. National Research Council Canada. (2021). "Sound Transmission Class Ratings for Typical Building Elements."

2. American Society for Testing and Materials. (2019). "ASTM E90-09: Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements."

3. Building Science Corporation. (2020). "Thermal and Acoustic Performance of Insulated Panels in Building Envelopes."

4. Journal of Building Engineering. (2022). "Acoustic Properties of Prefabricated Insulated Wall Panels: A Comprehensive Review."

5. International Journal of Acoustics and Vibration. (2021). "Advancements in Acoustic Insulation Technologies for Sustainable Building Design."