Understanding Prefabricated Thermal Panels

What Are Prefabricated Thermal Panels?

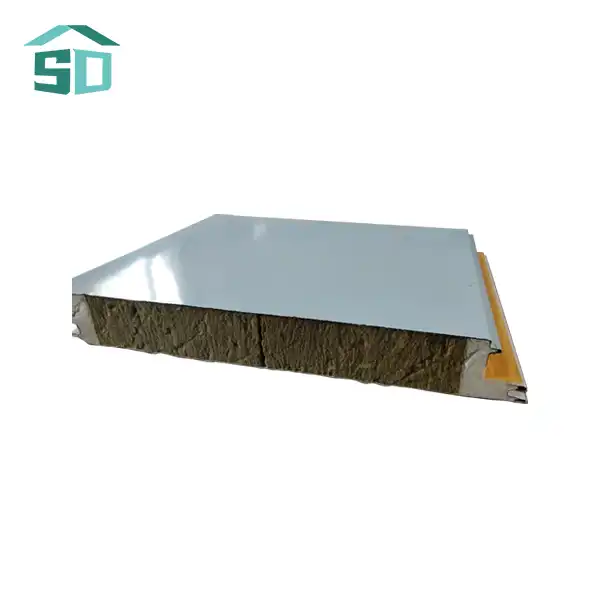

Prefabricated thermal panels are advanced building components designed to provide superior insulation and structural support. These panels consist of a high-performance insulating core sandwiched between two layers of durable material, typically metal or concrete. The prefabrication process ensures precise manufacturing under controlled conditions, resulting in panels that are ready for quick and easy installation on-site.

Weifang Sandong Building Materials Co., Ltd., a leading prefabricated thermal panels manufacturer, offers a wide range of panel options to suit various construction needs. Their panels are available in different thicknesses, materials, and finishes, allowing for customization based on specific project requirements.

Key Components of Prefabricated Thermal Panels

The effectiveness of prefabricated thermal panels lies in their carefully engineered components:

- Insulation Core: Usually made of materials like polyurethane, polystyrene, or mineral wool, providing excellent thermal resistance.

- Exterior Facing: Typically metal (steel or aluminum) or concrete, offering weather protection and structural integrity.

- Interior Facing: Often similar to the exterior, but can be customized for different interior finishes.

- Joining Systems: Engineered connections that ensure airtight and weatherproof installation.

Manufacturing Process of Prefabricated Thermal Panels

The production of prefabricated thermal panels involves a meticulous process:

- Material Selection: High-quality raw materials are chosen for optimal performance.

- Core Formation: The insulation core is precisely formed to the required thickness.

- Panel Assembly: The core is bonded to the exterior and interior facings under controlled conditions.

- Quality Control: Rigorous testing ensures each panel meets stringent performance standards.

- Finishing: Panels are cut to size and finished according to project specifications.

Energy-Saving Benefits of Prefabricated Thermal Panels

Superior Insulation Properties

Prefabricated thermal panels excel in providing exceptional insulation, significantly reducing heat transfer between the interior and exterior of a building. This superior insulation is achieved through:

- High R-Value: The insulation core offers a high resistance to heat flow, measured by the R-value.

- Minimal Thermal Bridges: The continuous insulation layer minimizes heat loss through structural elements.

- Airtight Construction: Precision-engineered joints reduce air leakage, further enhancing insulation performance.

By utilizing prefabricated thermal panels, buildings can maintain a more stable internal temperature, reducing the load on heating and cooling systems and resulting in significant energy savings.

Reduced HVAC Requirements

The enhanced insulation provided by prefabricated thermal panels leads to a reduced demand on HVAC systems:

- Lower Heating Costs: Better insulation means less heat escapes during colder months.

- Decreased Cooling Expenses: In warmer weather, the panels help keep interiors cool by blocking heat ingress.

- Smaller HVAC Systems: The improved thermal performance often allows for the installation of smaller, more efficient HVAC units.

These factors contribute to both immediate and long-term cost savings on energy bills and equipment investments.

Long-Term Energy Efficiency

Prefabricated thermal panels offer sustained energy efficiency benefits:

- Durability: High-quality panels maintain their insulation properties over many years.

- Resistance to Settling: Unlike some traditional insulation materials, these panels do not settle or compress over time, ensuring consistent performance.

- Weather Resistance: The panels' design protects against moisture intrusion, which can degrade insulation effectiveness.

This long-term performance translates to consistent energy savings throughout the lifespan of the building.

Cost-Saving Advantages of Prefabricated Thermal Panels

Reduced Construction Time and Labor Costs

Prefabricated thermal panels offer significant advantages in terms of construction efficiency:

- Quick Installation: Panels are designed for rapid assembly, reducing on-site construction time.

- Fewer Laborers Required: The simplified installation process requires fewer workers compared to traditional building methods.

- Reduced Equipment Needs: Less heavy machinery is typically needed for installation.

These factors contribute to lower overall construction costs and faster project completion times.

Minimized Material Waste

The use of prefabricated thermal panels leads to a reduction in material waste:

- Precise Manufacturing: Panels are produced to exact specifications, minimizing on-site cutting and waste.

- Recyclable Materials: Many prefabricated thermal panels are made from recyclable materials, reducing environmental impact.

- Fewer Shipments: The compact nature of the panels often results in fewer material deliveries to the construction site.

This efficiency in material use not only reduces costs but also aligns with sustainable building practices.

Long-Term Maintenance Savings

Prefabricated thermal panels offer long-term cost benefits through reduced maintenance needs:

- Durability: High-quality panels resist damage from weather and environmental factors.

- Easy Cleaning: Smooth surfaces of many panels allow for simple cleaning and maintenance.

- Fewer Repairs: The robust construction of prefabricated thermal panels often results in fewer necessary repairs over time.

These factors contribute to lower ongoing maintenance costs throughout the life of the building.

Conclusion

Prefabricated thermal panels represent a significant advancement in building technology, offering a powerful solution for energy efficiency and cost savings. By providing superior insulation, reducing construction time and waste, and offering long-term durability, these panels address many of the challenges faced in modern construction. As energy costs continue to rise and environmental concerns grow, the adoption of prefabricated thermal panels becomes increasingly attractive for both new construction and renovation projects.

Are you ready to experience the benefits of prefabricated thermal panels in your next building project? Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality panels tailored to meet your specific needs. Contact us at info@sdqsc.com to learn more about how our innovative solutions can help you save energy and reduce costs while enhancing the performance and sustainability of your buildings.

FAQ

How do prefabricated thermal panels compare to traditional insulation methods?

Prefabricated thermal panels often outperform traditional insulation in terms of R-value, air tightness, and ease of installation. They provide a more consistent insulation layer with fewer thermal bridges.

Are prefabricated thermal panels suitable for both new construction and renovations?

Yes, these panels are versatile and can be used in both new builds and retrofit projects, offering energy-saving benefits in various applications.

What is the typical lifespan of prefabricated thermal panels?

High-quality panels can last for several decades, often matching or exceeding the lifespan of the building itself when properly installed and maintained.

References

1.U.S. Department of Energy. (2022). "Insulation." Energy.gov.

2.International Energy Agency. (2021). "Buildings: A source of enormous untapped efficiency potential." IEA.org.

3.National Institute of Building Sciences. (2020). "Whole Building Design Guide: Building Envelope Design Guide." WBDG.org.