- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Prefabricated Thermal Panels vs Traditional Insulation: Which is Better?

In the ever-evolving world of construction, the debate between prefabricated thermal panels and traditional insulation methods continues to heat up. As energy efficiency and sustainability become increasingly important, builders and homeowners alike are seeking the most effective solutions for their projects. This article delves into the comparison between these two insulation options, exploring their benefits, drawbacks, and overall performance to help you make an informed decision for your next construction or renovation project.

Comprehending Prefabricated Thermal Panels

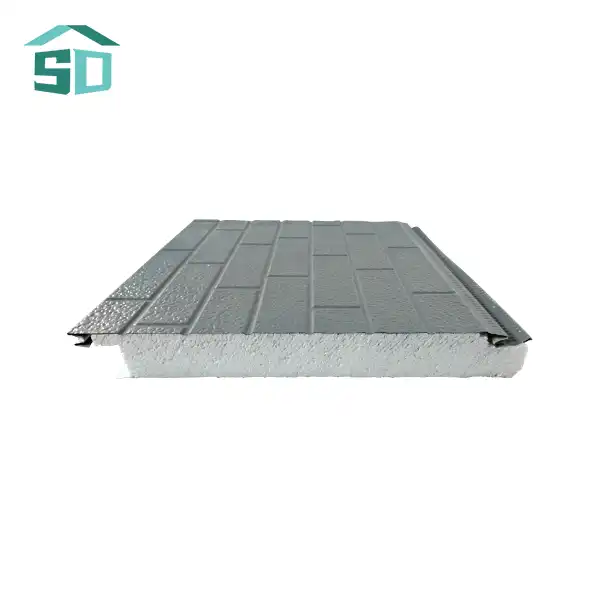

What Are Prefabricated Thermal Panels?

Prefabricated thermal panels are innovative building components that combine insulation and structural elements into a single, factory-made unit. These panels typically consist of a core insulation material sandwiched between two layers of structural facing, creating a robust and energy-efficient building solution. As a leading prefabricated thermal panels manufacturer, Weifang Sandong Building Materials Co., Ltd. offers a wide range of options to suit various construction needs.

Advantages of Prefabricated Thermal Panels

Prefabricated thermal panels offer numerous benefits that make them an attractive option for modern construction:

1. Superior Insulation: The engineered design of prefabricated thermal panels provides excellent thermal performance, reducing heat transfer and improving energy efficiency.

2. Rapid Installation: These panels are designed for quick and easy assembly, significantly reducing construction time and labor costs.

3. Versatility: Prefabricated thermal panels can be used for walls, roofs, and floors in various types of buildings, from residential homes to commercial structures.

4. Durability: With their robust construction, prefabricated thermal panels offer long-lasting performance and resistance to environmental factors.

5. Aesthetic Appeal: Available in a variety of finishes and colors, these panels can enhance the visual appeal of any structure.

Applications of Prefabricated Thermal Panels

Prefabricated thermal panels find application in a wide range of construction projects:

- Residential buildings

- Commercial offices

- Industrial facilities

- Cold storage warehouses

- Agricultural structures

- Educational institutions

The versatility of prefabricated thermal panels makes them suitable for both new construction and renovation projects, providing an efficient solution for improving building performance.

Traditional Insulation Methods: A Closer Look

Common Traditional Insulation Materials

Traditional insulation methods have been used for decades and include various materials such as:

- Fiberglass: Available in batts or loose-fill form, fiberglass is a common and cost-effective insulation option.

- Cellulose: Made from recycled paper products, cellulose insulation is eco-friendly and provides good thermal performance.

- Mineral Wool: Also known as rock wool, this material offers excellent fire resistance and sound insulation properties.

- Spray Foam: Applied as a liquid, spray foam expands to fill gaps and provide a tight air seal.

Pros and Cons of Traditional Insulation

Traditional insulation methods have their own set of advantages and disadvantages:

Pros:

- Generally lower initial cost

- Familiar to most contractors

- Can be easily retrofitted in existing buildings

Cons:

- Installation can be time-consuming and labor-intensive

- May settle or compress over time, reducing effectiveness

- Can be prone to moisture issues if not properly installed

- May require additional vapor barriers or air sealing

Performance of Traditional Insulation

While traditional insulation methods can provide adequate thermal performance, they often fall short when compared to the comprehensive benefits offered by prefabricated thermal panels. Traditional insulation typically requires additional components and careful installation to achieve optimal results, which can lead to inconsistencies in performance across the building envelope.

Comparing Prefabricated Thermal Panels and Traditional Insulation

Energy Efficiency and Thermal Performance

When it comes to energy efficiency, prefabricated thermal panels generally outperform traditional insulation methods. The engineered design of these panels eliminates thermal bridges and provides consistent insulation across the entire surface. This results in superior thermal performance and reduced energy consumption for heating and cooling.

Traditional insulation, while effective when properly installed, can suffer from gaps, compression, and settling over time, which can compromise its insulating properties. Additionally, traditional methods often require careful attention to vapor barriers and air sealing to prevent moisture issues and air infiltration.

Installation Process and Time

One of the most significant advantages of prefabricated thermal panels is the speed and ease of installation. These panels are designed for quick assembly, often requiring less than half the time needed for traditional insulation methods. This rapid installation process can lead to substantial savings in labor costs and project timelines.

Traditional insulation installation is typically more time-consuming and labor-intensive. It often involves cutting materials to fit, dealing with multiple components, and ensuring proper coverage and density. This process can be particularly challenging in areas with complex geometries or limited access.

Long-Term Durability and Maintenance

Prefabricated thermal panels are engineered for long-term performance and durability. Their robust construction and factory-controlled quality ensure consistent performance over time with minimal maintenance requirements. These panels are also resistant to moisture, mold, and pests, further enhancing their longevity.

Traditional insulation materials may require more frequent maintenance and inspection. They can be susceptible to settling, compression, and moisture absorption, which can degrade their performance over time. Regular checks and potential replacements may be necessary to maintain optimal insulation levels.

Cost Considerations

While the initial cost of prefabricated thermal panels may be higher than traditional insulation methods, it's essential to consider the long-term value. The superior energy efficiency, faster installation, and reduced maintenance requirements of prefabricated thermal panels can result in significant cost savings over the life of the building.

Traditional insulation often has a lower upfront cost, which can be attractive for budget-conscious projects. However, the potential for higher labor costs during installation and increased energy expenses over time should be factored into the overall cost analysis.

Environmental Impact

Prefabricated thermal panels can contribute to more sustainable building practices. Their energy-efficient performance reduces a building's carbon footprint, and many panels are made with recyclable materials. The precise manufacturing process also minimizes on-site waste.

Traditional insulation materials vary in their environmental impact. While some options like cellulose are made from recycled materials, others may have higher embodied energy or contain potentially harmful chemicals. The installation process for traditional insulation can also generate more on-site waste.

Design Flexibility and Aesthetics

Prefabricated thermal panels offer significant design flexibility and aesthetic options. They are available in various colors, textures, and finishes, allowing architects and designers to achieve their desired look without compromising on performance. The sleek, uniform appearance of these panels can contribute to a modern and polished exterior.

Traditional insulation methods are typically hidden within wall cavities and don't contribute directly to the building's aesthetics. This can provide more freedom in choosing exterior finishes but may require additional materials and labor to achieve the desired look.

Conclusion

In the comparison between prefabricated thermal panels and traditional insulation, it's clear that both options have their merits. However, prefabricated thermal panels offer a compelling combination of energy efficiency, rapid installation, durability, and design flexibility that makes them an excellent choice for modern construction projects.

While traditional insulation methods may still have their place in certain applications, the comprehensive benefits of prefabricated thermal panels position them as a superior solution for many building types. As construction practices continue to evolve towards greater sustainability and efficiency, prefabricated thermal panels are poised to play an increasingly important role in shaping the buildings of the future.

Are you ready to experience the benefits of prefabricated thermal panels for your next project? Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality prefabricated thermal panels designed to meet your specific needs. Our expert team is ready to help you find the perfect solution for your construction or renovation project. Contact us today at info@sdqsc.com to learn more about how our prefabricated thermal panels can enhance your building's performance and aesthetics.

FAQ

How do prefabricated thermal panels compare to traditional insulation in terms of R-value?

Prefabricated thermal panels typically offer higher R-values per inch of thickness compared to traditional insulation materials, providing superior thermal performance in a more compact solution.

Can prefabricated thermal panels be used in retrofit projects?

Yes, prefabricated thermal panels can be an excellent choice for retrofit projects, offering improved insulation and a fresh exterior appearance in one application.

Are prefabricated thermal panels suitable for all climate zones?

Prefabricated thermal panels can be engineered to suit various climate zones, with different insulation thicknesses and materials available to meet specific regional requirements.

How long do prefabricated thermal panels typically last?

When properly installed and maintained, prefabricated thermal panels can last for several decades, often outlasting traditional insulation materials.

References

1. U.S. Department of Energy. (2022). Insulation Materials.

2. BuildingGreen. (2021). Insulation: The Building Envelope's Unsung Hero.

3. ASHRAE. (2021). ASHRAE Handbook - Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers.

4. International Code Council. (2021). International Energy Conservation Code.

5. National Institute of Building Sciences. (2020). Whole Building Design Guide: Building Envelope Design Guide.