Understanding Metal Insulated Sandwich Panels

What Are Metal Insulated Sandwich Panels?

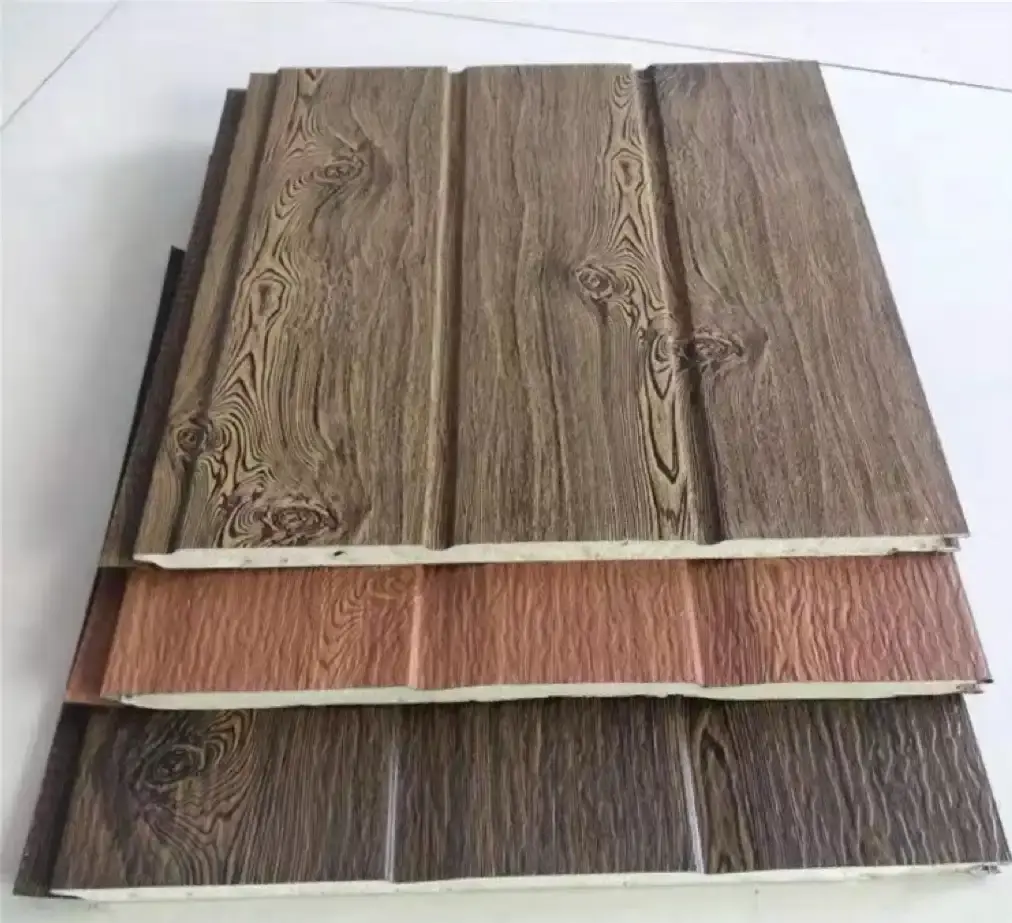

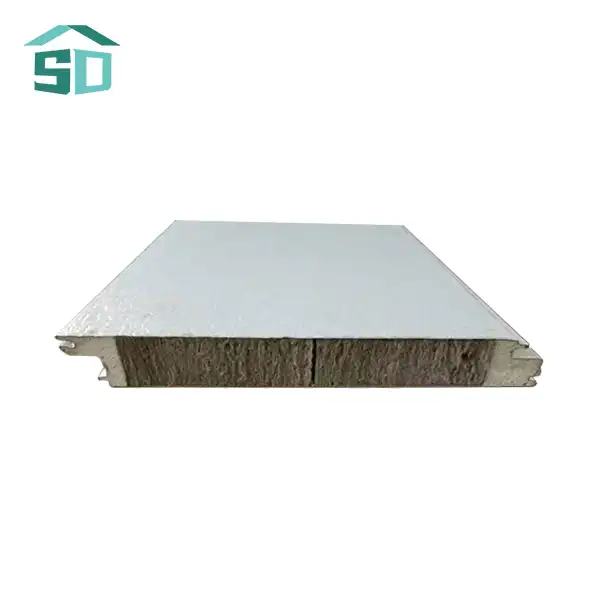

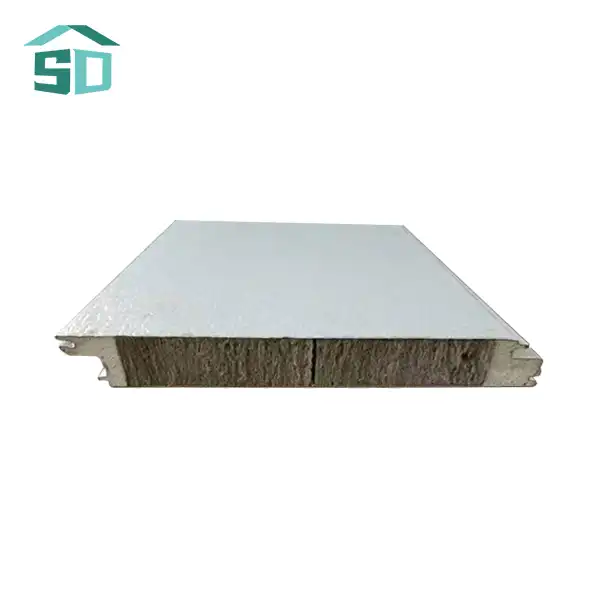

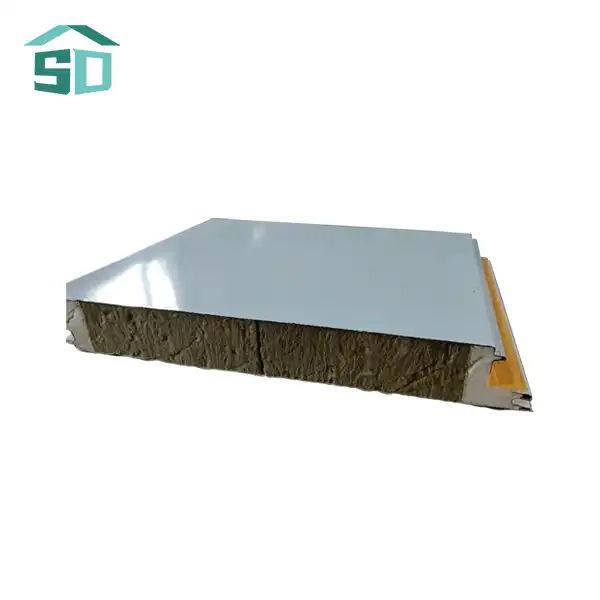

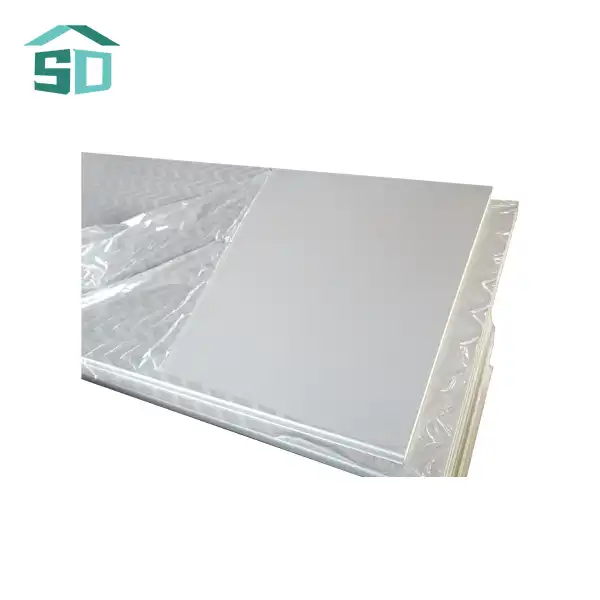

Metal insulated sandwich panels are advanced building components that consist of two metal facings enclosing an insulating core. This innovative design creates a "sandwich" structure that offers superior thermal performance and structural strength. The metal facings, typically made of steel or aluminum, provide durability and weather resistance, while the insulating core, often composed of materials like polyurethane foam or mineral wool, ensures excellent thermal insulation.

These panels are engineered to meet the demanding requirements of industrial buildings, offering a perfect balance of functionality and efficiency. The metal insulated sandwich panel manufacturer plays a crucial role in ensuring the quality and performance of these panels, utilizing state-of-the-art production techniques to create products that meet stringent industry standards.

Key Components of Metal Insulated Sandwich Panels

To fully appreciate the capabilities of metal insulated sandwich panels, it's essential to understand their key components:

- Exterior Metal Facing: This layer provides weather protection and contributes to the panel's overall strength. It can be customized with various finishes and colors to enhance the building's aesthetic appeal.

- Insulating Core: The heart of the panel, this layer offers thermal insulation and contributes to the panel's structural integrity. Different insulating materials can be used depending on the specific requirements of the project.

- Interior Metal Facing: This layer provides a finished interior surface and adds to the panel's overall durability.

- Jointing System: Engineered connections between panels ensure a tight seal, enhancing thermal performance and weather resistance.

Each component of the metal insulated sandwich panel is carefully designed and manufactured to work in harmony, creating a building solution that excels in performance and longevity.

Manufacturing Process of Metal Insulated Sandwich Panels

The production of metal insulated sandwich panels involves a sophisticated manufacturing process that ensures consistent quality and performance. Leading metal insulated sandwich panel manufacturers employ advanced production lines and rigorous quality control systems to create panels that meet the highest industry standards.

The manufacturing process typically includes the following steps:

1. Preparation of metal facings, including cleaning and profiling

2. Application of adhesive to metal facings

3. Injection or layering of the insulating core material

4. Pressing and curing of the panel assembly

5. Cutting and finishing of panels to specified dimensions

6. Quality control inspections, including tests for thickness, mechanical strength, and flame retardancy

This meticulous process ensures that each metal insulated sandwich panel meets the exacting standards required for industrial applications, providing builders and property owners with a reliable and high-performance building solution.

Benefits of Metal Insulated Sandwich Panels in Industrial Buildings

Thermal Efficiency and Energy Savings

One of the primary advantages of metal insulated sandwich panels is their exceptional thermal performance. The insulating core of these panels significantly reduces heat transfer between the interior and exterior of the building, helping to maintain a consistent indoor temperature. This thermal efficiency translates into substantial energy savings for industrial facilities, reducing the load on heating and cooling systems and lowering overall operational costs.

Metal insulated sandwich panels offer superior R-values compared to traditional building materials, making them an excellent choice for industrial buildings that require strict temperature control. The effectiveness of these panels in thermal insulation can lead to energy savings of up to 30% in some applications, making them a cost-effective solution in the long run.

Structural Integrity and Durability

The unique construction of metal insulated sandwich panels provides exceptional structural strength and durability. The combination of metal facings and an insulating core creates a lightweight yet robust panel that can withstand various environmental stresses. This structural integrity is particularly beneficial in industrial settings where buildings may be subject to heavy loads, vibrations, or extreme weather conditions.

Metal insulated sandwich panels are engineered to resist:

- Wind loads

- Snow loads

- Seismic forces

- Impact damage

- Corrosion

The durability of these panels ensures a long service life for industrial buildings, reducing maintenance costs and the need for frequent repairs or replacements. Many metal insulated sandwich panel manufacturers offer warranties that reflect the confidence they have in their products' longevity and performance.

Fire Resistance and Safety

Safety is paramount in industrial buildings, and metal insulated sandwich panels offer excellent fire resistance properties. Many panels are designed to meet stringent fire safety standards, providing valuable time for evacuation and fire suppression in the event of an emergency.

The fire performance of metal insulated sandwich panels can be attributed to several factors:

- Non-combustible metal facings

- Fire-resistant insulating cores (e.g., mineral wool)

- Interlocking joint systems that help prevent fire spread

- Factory-applied fire-resistant coatings

When selecting metal insulated sandwich panels for industrial applications, it's crucial to work with a reputable metal insulated sandwich panel manufacturer that can provide panels with the appropriate fire ratings for the specific building requirements and local regulations.

Applications of Metal Insulated Sandwich Panels in Industrial Settings

Warehouses and Distribution Centers

Metal insulated sandwich panels are extensively used in the construction of warehouses and distribution centers. These facilities often require large, open spaces with minimal internal support structures, making the panels an ideal building solution. The thermal efficiency of metal insulated sandwich panels helps maintain stable temperatures for stored goods, while their durability ensures the building can withstand the rigors of daily operations.

Key benefits for warehouses and distribution centers include:

- Rapid construction times

- Excellent insulation for temperature-sensitive goods

- Low maintenance requirements

- Flexibility for future expansion or modification

Many metal insulated sandwich panel manufacturers offer specialized panels designed specifically for warehouse applications, featuring enhanced load-bearing capabilities and impact resistance.

Manufacturing Facilities

In manufacturing environments, metal insulated sandwich panels provide a versatile building envelope solution that can accommodate various production processes. The panels' ability to create controlled environments is particularly valuable in industries where temperature and humidity control are critical to product quality and worker comfort.

Metal insulated sandwich panels in manufacturing facilities offer:

- Customizable interior finishes for clean room applications

- Excellent acoustic properties to reduce noise transmission

- Chemical resistance for specialized industrial processes

- Easy integration with mechanical and electrical systems

The adaptability of metal insulated sandwich panels allows manufacturers to create optimized spaces that enhance productivity and meet specific industry regulations.

Cold Storage and Food Processing Plants

The food industry relies heavily on metal insulated sandwich panels for cold storage facilities and food processing plants. The superior insulation properties of these panels are crucial for maintaining precise temperature control, ensuring food safety, and reducing energy consumption in these energy-intensive environments.

Advantages of using metal insulated sandwich panels in cold storage and food processing include:

- Excellent vapor barriers to prevent moisture infiltration

- Hygienic surfaces that are easy to clean and maintain

- Resistance to mold and bacterial growth

- Ability to create airtight environments for controlled atmospheres

Metal insulated sandwich panel manufacturers often produce specialized panels with food-grade finishes and enhanced insulation properties specifically for these applications, ensuring compliance with stringent food safety regulations.

Conclusion

Metal insulated sandwich panels have revolutionized the construction of industrial buildings, offering a perfect blend of thermal efficiency, structural integrity, and versatility. From warehouses to cold storage facilities, these panels provide solutions that meet the complex demands of modern industrial environments. The benefits of reduced energy costs, improved safety, and long-term durability make metal insulated sandwich panels an investment that pays dividends for years to come.

As industrial construction continues to evolve, the role of metal insulated sandwich panels is likely to grow even further. Their adaptability to various applications and ability to meet stringent performance requirements position them as a cornerstone of sustainable and efficient industrial building design. For those seeking to enhance their industrial facilities, exploring the possibilities offered by metal insulated sandwich panels is a step towards creating more efficient, safe, and cost-effective buildings.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality metal insulated sandwich panels that meet the diverse needs of industrial construction projects. Our advanced manufacturing processes and rigorous quality control ensure that each panel delivers exceptional performance and longevity. To learn more about our products and how they can benefit your next industrial building project, please contact us at info@sdqsc.com.

FAQs

What is the typical lifespan of metal insulated sandwich panels?

With proper installation and maintenance, metal insulated sandwich panels can last 30 years or more, depending on the environment and usage conditions.

Can metal insulated sandwich panels be recycled?

Yes, many components of metal insulated sandwich panels, particularly the metal facings, can be recycled at the end of their life cycle, contributing to sustainable building practices.

Are metal insulated sandwich panels suitable for retrofitting existing buildings?

Absolutely. Metal insulated sandwich panels can be an excellent solution for upgrading the thermal performance and appearance of existing industrial buildings, often with minimal disruption to operations.

References

1. American Iron and Steel Institute. (2021). "Steel Sandwich Panel Construction."

2. International Association of Certified Home Inspectors. (2022). "Insulated Metal Panels."

3. U.S. Department of Energy. (2020). "Insulation Materials."

4. National Fire Protection Association. (2021). "NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components."