The Science Behind Green Thermal Insulation Panels

Understanding R-Value and Its Importance

R-value is a crucial metric in the world of insulation, measuring the thermal resistance of materials. The higher the R-value, the better the insulation performs. Green thermal insulation panels are engineered to maximize this value, offering superior heat flow resistance compared to traditional insulation methods. This enhanced performance is achieved through the use of advanced materials such as polyurethane, polystyrene, rock wool, or glass wool, each carefully selected for its insulative properties.

The importance of R-value cannot be overstated in modern construction. As energy costs rise and environmental concerns grow, the demand for highly efficient insulation solutions has skyrocketed. Green thermal insulation panels address this need by providing a robust barrier against heat transfer, effectively maintaining desired indoor temperatures with minimal energy expenditure. This not only leads to significant cost savings but also contributes to a reduced carbon footprint, aligning with global sustainability goals.

Composition and Manufacturing Process

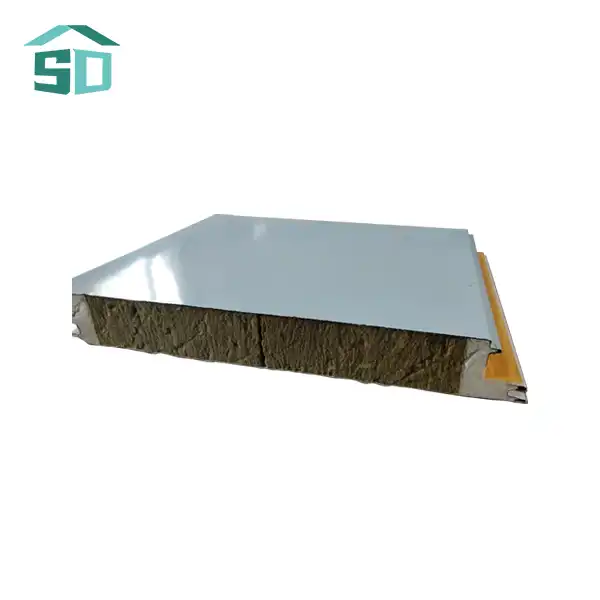

The composition of green thermal insulation panels is a testament to innovative material science. These panels typically consist of an insulation core sandwiched between two facings. The core material, which could be polyurethane, polystyrene, rock wool, or glass wool, is chosen for its exceptional insulative properties and eco-friendly credentials. The facings, often made from aluminum, steel, or stainless steel, provide structural integrity and protection against environmental factors.

The manufacturing process of these panels is equally sophisticated. It involves the careful selection and testing of raw materials, ensuring only the highest quality components are used. Advanced production lines equipped with state-of-the-art technology facilitate the precise layering and bonding of materials. Rigorous quality control measures are implemented at every stage, from inspecting the thickness and mechanical strength of the panels to testing their flame retardancy and overall appearance. This meticulous approach results in panels that not only meet but often exceed industry standards for performance and safety.

Environmental Impact and Sustainability

The "green" in green thermal insulation panels refers not just to their energy-saving capabilities but also to their environmental friendliness. Many of these panels are manufactured using recyclable materials, contributing to a circular economy and reducing waste. The production process is often optimized to minimize energy consumption and emissions, further reducing the environmental impact.

Moreover, the longevity and durability of these panels mean they require less frequent replacement, reducing long-term resource consumption. Their superior insulation properties also contribute to a significant reduction in a building's energy usage over its lifetime. This dual benefit of resource conservation during production and energy savings during use makes green thermal insulation panels a truly sustainable choice for modern construction.

Optimizing Wall Systems with Green Thermal Insulation Panels

Integration into Various Building Types

The versatility of green thermal insulation panels makes them suitable for a wide range of building types. In residential construction, these panels can be seamlessly integrated into exterior walls, providing homeowners with enhanced comfort and reduced energy bills. For commercial buildings, the panels offer an efficient solution to maintain consistent temperatures across large spaces, crucial for office environments and retail establishments.

Industrial applications benefit greatly from the robust nature of these panels. Warehouses and manufacturing facilities often require strict temperature control, which these panels can provide while withstanding harsh industrial environments. Even in specialized constructions like data centers, where temperature regulation is critical, green thermal insulation panels prove their worth by maintaining optimal conditions with minimal energy input.

Installation Techniques and Best Practices

Proper installation is key to maximizing the performance of green thermal insulation panels. The process typically begins with careful preparation of the wall surface, ensuring it's clean and free of debris. Accurate measurements are crucial to determine the correct panel size, minimizing waste and ensuring a snug fit.

The panels are then secured using appropriate fasteners, with special attention paid to creating a tight seal against the wall surface. This step is crucial in preventing thermal bridges that could compromise the insulation's effectiveness. Edges and joints are sealed meticulously to enhance both thermal performance and aesthetics. Many manufacturers provide specialized accessories like sealing strips, compatible fasteners, and edge trims to ensure a professional finish.

Performance Metrics and Energy Savings

The performance of green thermal insulation panels is often quantified through various metrics. Beyond R-value, factors such as thermal bridging reduction, air infiltration resistance, and moisture control are considered. These panels typically achieve high scores across all these parameters, resulting in comprehensive thermal protection.

The energy savings realized through the use of these panels can be substantial. Buildings equipped with green thermal insulation panels often see a significant reduction in heating and cooling costs, sometimes up to 30% or more compared to traditional insulation methods. This translates to lower energy bills for building owners and reduced strain on power grids, particularly during peak usage periods. Over time, these savings can offset the initial investment in the panels, making them a cost-effective choice in the long run.

Advanced Features and Future Developments

Customization Options for Aesthetic and Functional Needs

One of the most appealing aspects of green thermal insulation panels is their customizability. Manufacturers offer a wide range of color options, including coated and anodized finishes, allowing architects and designers to achieve their desired aesthetic without compromising on insulation performance. The panels can be tailored to fit specific project requirements, with thicknesses ranging from 50mm to 200mm to suit different insulation needs.

Beyond aesthetics, these panels can be customized for specific functional requirements. For instance, panels intended for use in high-moisture environments can be treated for enhanced water resistance. Those destined for areas with strict fire safety regulations can be manufactured to meet or exceed Class A fire ratings. This flexibility allows for the creation of bespoke insulation solutions that address unique project challenges while maintaining optimal thermal performance.

Smart Integration and Building Management Systems

The future of green thermal insulation panels lies in their integration with smart building technologies. Advanced sensors can be embedded within the panels to monitor temperature, humidity, and even air quality in real-time. This data can be fed into building management systems, allowing for dynamic adjustments to heating, cooling, and ventilation systems for optimal energy efficiency.

Some cutting-edge developments include panels with phase-change materials that can absorb or release heat as needed, providing an additional layer of temperature regulation. Others are exploring the integration of photovoltaic cells into the panel surfaces, turning walls into energy-generating assets. These innovations promise to transform green thermal insulation panels from passive elements into active contributors to a building's overall energy strategy.

Regulatory Landscape and Future Standards

The regulatory landscape surrounding building insulation is evolving rapidly, driven by increasing awareness of climate change and the need for energy conservation. Many countries are implementing stricter energy efficiency standards for new constructions and renovations. Green thermal insulation panels are well-positioned to meet and exceed these standards, often helping buildings achieve certifications like LEED or BREEAM.

Looking ahead, we can expect even more stringent regulations concerning the environmental impact of building materials. This may lead to further innovations in the composition of green thermal insulation panels, potentially incorporating more bio-based or recycled materials. The focus on lifecycle assessment is likely to intensify, pushing manufacturers to consider not just the performance of their panels during use, but also their environmental impact during production and at the end of their life cycle.

Conclusion

Green thermal insulation panels represent a significant leap forward in building energy efficiency and sustainable construction practices. Their ability to maximize R-value while offering customization, durability, and eco-friendly credentials makes them an invaluable tool in the quest for more energy-efficient buildings. As we continue to face environmental challenges and stricter energy regulations, these panels will undoubtedly play a crucial role in shaping the future of construction.

For those looking to leverage the benefits of green thermal insulation panels in their next project, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality solutions. Our expert team is ready to assist you in selecting the perfect panels for your specific needs. To learn more about our products and how they can enhance your building's energy performance, please don't hesitate to contact us at info@sdqsc.com.

FAQ

What makes green thermal insulation panels "green"?

These panels are considered "green" due to their energy-saving properties, use of recyclable materials, and contribution to sustainable building practices.

How long do green thermal insulation panels typically last?

With proper installation and maintenance, these panels can last for several decades, often outlasting the building's lifetime.

Can green thermal insulation panels be used in retrofit projects?

Yes, these panels are versatile and can be effectively used in both new constructions and retrofit projects to improve energy efficiency.

References

1.U.S. Department of Energy. (2023). Insulation.

2.International Energy Agency. (2022). Buildings: A source of enormous untapped efficiency potential.

3.Green Building Council. (2023). LEED rating system. USGBC.

4.Building Research Establishment. (2023). BREEAM.