The Anatomy of Honeycomb Sandwich Panels: Strength Meets Efficiency

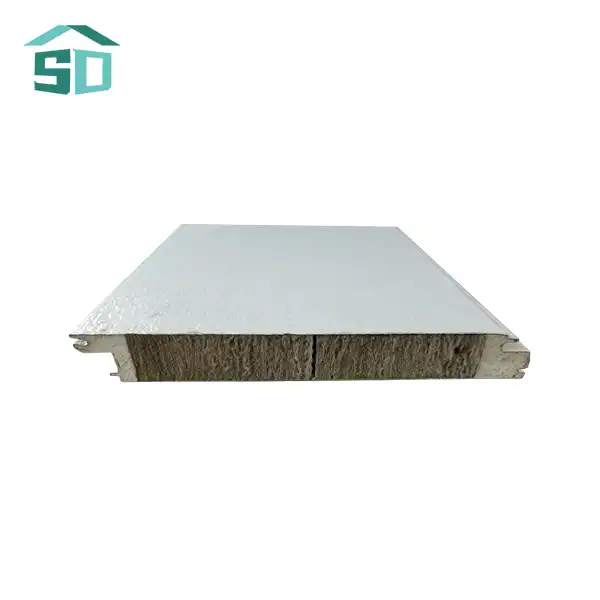

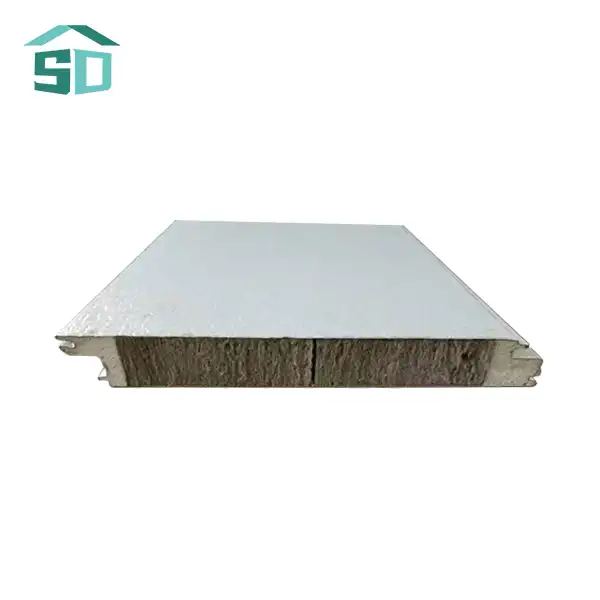

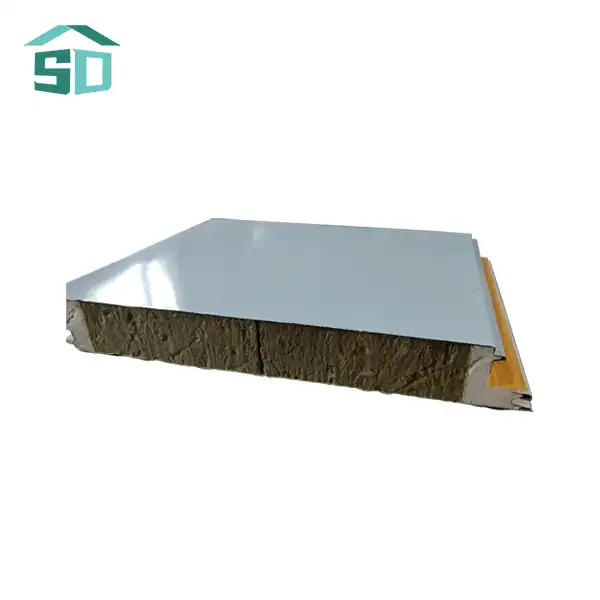

Core Structure: The Heart of Honeycomb Technology

At the center of honeycomb sandwich panels lies their defining feature: the honeycomb core. This intricate structure, typically made from aluminum or thermoplastic materials, mimics the hexagonal pattern found in natural beehives. The geometric precision of this design allows for an optimal balance between strength and weight reduction. By distributing forces evenly across the panel, the honeycomb core provides remarkable resistance to compression and shear stress, ensuring the panel maintains its integrity under various loads.

Facing Materials: Protective Layers for Enhanced Performance

Complementing the honeycomb core are the facing materials, which form the outer layers of the sandwich panel. These skins can be customized based on specific project requirements, with options ranging from aluminum and steel to fiberglass reinforced plastics. The selection of facing materials plays a crucial role in determining the panel's overall properties, including its fire resistance, corrosion resistance, and aesthetic appeal. High-quality facings not only protect the core but also contribute to the panel's structural strength and durability.

Bonding Technology: Ensuring Seamless Integration

The effectiveness of honeycomb sandwich panels relies heavily on the bonding between the core and facing materials. Advanced adhesive technologies are employed to create a strong, uniform bond that maximizes the panel's performance. This seamless integration ensures that the panel functions as a single unit, distributing loads efficiently and maintaining its structural integrity over time. The result is a lightweight yet incredibly robust panel that can withstand the rigors of various environmental conditions and structural demands.

Unparalleled Benefits: Why Honeycomb Sandwich Panels Stand Out?

Lightweight Design: Reducing Structural Load Without Compromising Strength

One of the most significant advantages of honeycomb sandwich panels is their exceptional strength-to-weight ratio. By utilizing a honeycomb core, these panels achieve remarkable structural integrity while maintaining a lightweight profile. This characteristic is particularly beneficial in construction projects where weight reduction is crucial, such as in high-rise buildings or structures with limited load-bearing capacity. The lightweight nature of these panels also simplifies installation processes, reducing labor costs and construction time.

Thermal Efficiency: Advanced Insulation for Energy Conservation

Honeycomb sandwich panels excel in thermal insulation, making them an excellent choice for energy-efficient building designs. The air pockets within the honeycomb structure act as natural insulators, significantly reducing heat transfer between interior and exterior environments. This enhanced thermal performance translates to lower energy consumption for heating and cooling, contributing to reduced operational costs and a smaller carbon footprint. The panels' insulation properties also help maintain comfortable indoor temperatures, improving overall occupant comfort.

Fire Resistance: Safeguarding Structures with Inert Materials

Safety is paramount in construction, and honeycomb sandwich panels address this concern with their inherent fire-resistant properties. Many honeycomb cores are made from inert materials that do not contribute to flame spread or smoke generation. When combined with fire-resistant facing materials, these panels create a formidable barrier against fire propagation. This characteristic is especially valuable in high-risk environments or buildings where fire safety is a critical consideration, providing occupants with additional time for safe evacuation in the event of a fire.

Versatility and Applications: Expanding Horizons in Construction

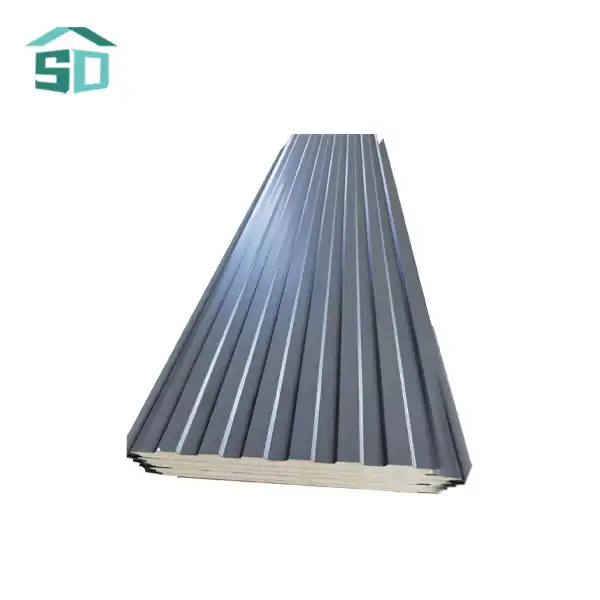

Exterior Cladding: Enhancing Facade Performance and Aesthetics

Honeycomb sandwich panels have gained popularity as an exterior cladding solution, offering a perfect blend of functionality and visual appeal. Their lightweight nature allows for easy installation on a variety of building types, from residential complexes to commercial skyscrapers. The panels' customizable facing materials open up a world of design possibilities, enabling architects to create striking facades that stand out. Moreover, the durability and weather resistance of these panels ensure that the building's exterior maintains its appearance and performance over time, even in harsh environmental conditions.

Interior Partitions: Flexible Space Division with Added Benefits

In interior applications, honeycomb sandwich panels provide an innovative solution for creating flexible and efficient spaces. Their lightweight nature allows for easy reconfiguration of interior layouts, making them ideal for open-plan offices or adaptable living spaces. The panels' excellent acoustic properties help in reducing sound transmission between rooms, enhancing privacy and comfort. Additionally, the smooth surface of the panels can be easily finished with a variety of materials, allowing for seamless integration with different interior design schemes.

Specialized Applications: From Transportation to Aerospace

The unique properties of honeycomb sandwich panels have led to their adoption in specialized industries beyond traditional construction. In the transportation sector, these panels are used in the manufacture of lightweight yet strong components for vehicles, trains, and ships, contributing to improved fuel efficiency.

The aerospace industry also leverages the exceptional strength-to-weight ratio of honeycomb panels in aircraft construction, where every gram saved translates to significant performance gains. These diverse applications showcase the versatility and adaptability of honeycomb sandwich panel technology across various fields.

Conclusion

Honeycomb sandwich panels represent a significant leap forward in construction technology, offering a unique combination of strength, efficiency, and versatility. As the industry continues to prioritize sustainable and high-performance building solutions, these panels stand out as a compelling choice for architects, engineers, and builders alike. By providing long-lasting walls that are lightweight, thermally efficient, and fire-resistant, honeycomb sandwich panels contribute to the creation of safer, more comfortable, and environmentally friendly structures.

As we look to the future of construction, it's clear that these innovative panels will play an increasingly important role in shaping the buildings of tomorrow. For those seeking to elevate their construction projects with cutting-edge materials, exploring the potential of honeycomb sandwich panels is a step in the right direction. To learn more about how these panels can benefit your next project, contact us at info@sdqsc.com for expert guidance and solutions tailored to your specific needs.