Introducing Corrugated Sandwich Panels: Structure and Composition

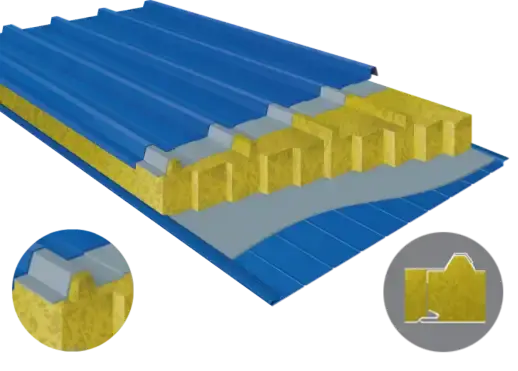

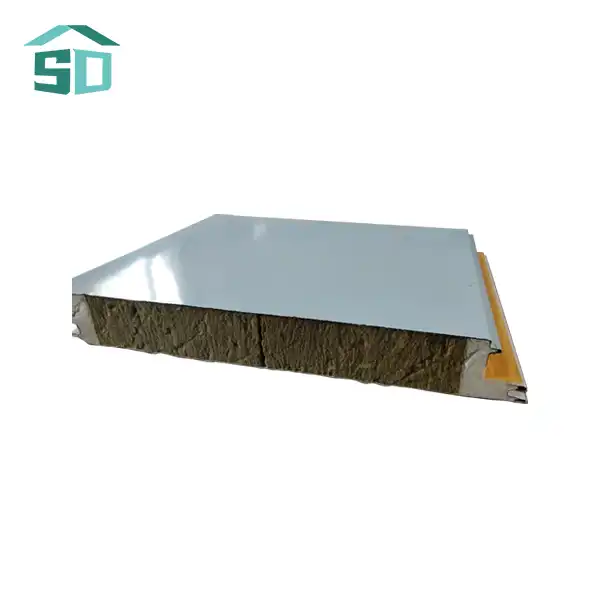

To fully appreciate the mechanical advantages of corrugated-core sandwich structures, it's essential to understand their basic composition and design principles. Corrugated sandwich panels are engineered structures that consist of three main components: two face sheets and a corrugated core sandwiched between them.

Face Sheets: The Outer Layers

The face sheets of a corrugated sandwich panel serve as the exterior surfaces and play a crucial role in determining the panel's overall performance. These sheets are typically made from materials such as steel, aluminum, or fiber-reinforced composites, depending on the specific application requirements. The face sheets provide the primary resistance to bending and in-plane loads, contributing significantly to the panel's stiffness and strength.

In the context of building materials, Weifang Sandong Building Materials Co., Ltd., a leading corrugated sandwich panel supplier, offers a range of high-quality face sheet options. Their advanced production lines ensure strict quality control, including comprehensive inspections of steel coils and aluminum foil for optimal mechanical strength and durability.

Corrugated Core: The Heart of the Structure

The corrugated core is the defining feature of these sandwich structures and the primary source of their mechanical advantages. This core consists of a wave-like or zigzag pattern that runs perpendicular to the face sheets. The corrugation can be made from various materials, including metals, polymers, or composite materials.

The geometry of the corrugated core is carefully engineered to optimize load distribution and energy absorption. Common corrugation patterns include sinusoidal waves, trapezoidal shapes, and triangular profiles. Each pattern offers unique mechanical properties and can be tailored to suit specific application requirements.

Bonding and Assembly

The effectiveness of a corrugated sandwich panel relies heavily on the bonding between the face sheets and the corrugated core. Advanced adhesive technologies and bonding techniques are employed to ensure a strong, durable connection between the components. This integration is crucial for the panel to function as a cohesive unit and fully leverage its mechanical advantages.

Weifang Sandong Building Materials Co., Ltd. utilizes state-of-the-art bonding processes in their production of corrugated sandwich panels. Their quality control system includes rigorous testing of the bonding strength to ensure the panels meet the highest standards of structural integrity.

Mechanical Advantages of Corrugated Sandwich Panels

The unique structure of corrugated sandwich panels confers several significant mechanical advantages that make them highly desirable in various engineering applications. Let's explore these advantages in detail.

Superior Stiffness-to-Weight Ratio

One of the most notable mechanical advantages of corrugated sandwich panels is their exceptional stiffness-to-weight ratio. This property refers to the panel's ability to resist deformation under load while maintaining a relatively low overall weight. The corrugated core plays a crucial role in achieving this balance.

The corrugated structure effectively increases the moment of inertia of the panel without significantly increasing its mass. This geometric arrangement allows the panel to resist bending forces more efficiently than solid materials of equivalent weight. As a result, corrugated sandwich panels can provide the same level of structural support as heavier alternatives, making them ideal for applications where weight reduction is critical, such as in aerospace or automotive industries.

Enhanced Load-Bearing Capacity

Corrugated sandwich panels exhibit remarkable load-bearing capabilities, surpassing many traditional building materials in terms of strength-to-weight performance. The corrugated core acts as a series of miniature beams, distributing applied loads across the entire structure.

When a load is applied to a corrugated sandwich panel, the face sheets work in tension and compression, while the corrugated core resists shear forces. This synergistic interaction between components allows the panel to withstand higher loads than its individual parts could handle separately. The result is a structure that can support substantial weights while remaining lightweight and efficient.

Weifang Sandong Building Materials Co., Ltd. leverages this mechanical advantage in their corrugated sandwich panels, providing building solutions that offer superior load-bearing capacity for various construction projects, from residential complexes to municipal buildings.

Excellent Energy Absorption Properties

Another significant mechanical advantage of corrugated sandwich panels is their ability to absorb and dissipate energy effectively. This property is particularly valuable in applications where impact resistance or vibration damping is required.

The corrugated core's geometry allows it to deform in a controlled manner when subjected to impact or dynamic loads. As the core compresses, it absorbs energy through plastic deformation and friction between the corrugations. This energy absorption mechanism helps protect the face sheets and any underlying structures from damage.

Moreover, the air spaces within the corrugated core contribute to the panel's acoustic and thermal insulation properties. This multifunctional aspect of corrugated sandwich panels makes them particularly attractive for use in building facades and transportation applications where energy efficiency and sound dampening are important considerations.

Applications and Future Prospects of Corrugated Sandwich Panels

The unique mechanical advantages of corrugated sandwich panels have led to their adoption in a wide range of industries and applications. As technology advances and new materials are developed, the potential for these structures continues to expand.

Construction and Architecture

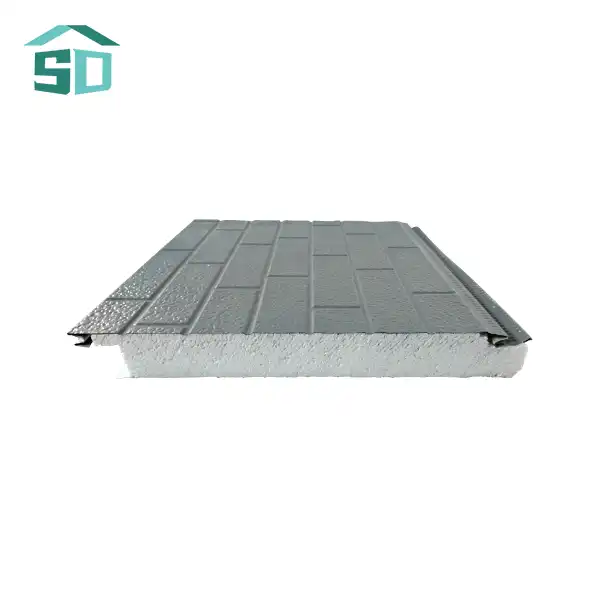

In the construction industry, corrugated sandwich panels have revolutionized building design and performance. Their lightweight nature, coupled with high strength and insulation properties, makes them ideal for use in exterior cladding, roofing, and interior partitions.

Weifang Sandong Building Materials Co., Ltd. has been at the forefront of this revolution, offering a diverse range of corrugated sandwich panels for various architectural applications. Their products find use in residential complexes, offices, villas, and even historic building renovations, providing both aesthetic appeal and functional benefits.

The panels' ability to span large distances with minimal support structures allows for more open, flexible interior spaces in buildings. Additionally, their excellent thermal insulation properties contribute to improved energy efficiency in structures, aligning with modern sustainability goals.

Aerospace and Transportation

The aerospace industry has long recognized the value of corrugated sandwich panels in aircraft design. The panels' high stiffness-to-weight ratio is particularly advantageous in this field, where every gram of weight savings translates to fuel efficiency and increased payload capacity.

Corrugated sandwich panels are used in various aircraft components, including floor panels, cargo bay linings, and interior partitions. Their energy absorption properties also make them valuable in creating safer, more crash-resistant structures in both aircraft and automotive applications.

In the automotive sector, corrugated sandwich panels are increasingly being explored for use in vehicle bodies and components. Their ability to provide strength and rigidity while reducing overall vehicle weight aligns perfectly with the industry's push towards lighter, more fuel-efficient vehicles.

Marine and Offshore Applications

The marine industry has also embraced corrugated sandwich panels for their unique combination of properties. In shipbuilding, these panels offer weight savings without compromising on strength, allowing for the construction of faster, more efficient vessels.

Corrugated sandwich panels are particularly useful in creating bulkheads, decking, and superstructures in ships. Their corrosion resistance (when made with appropriate materials) and ability to withstand the harsh marine environment make them an attractive option for both commercial and military naval applications.

In offshore structures such as oil rigs and wind turbines, corrugated sandwich panels provide a lightweight yet durable solution for various components, from flooring to equipment housings. Their energy absorption properties also make them valuable in creating blast-resistant structures in these high-risk environments.

Future Innovations and Research Directions

As the demand for more efficient, sustainable, and high-performance materials grows, research into corrugated sandwich panels continues to evolve. Some promising areas of development include:

- Advanced Materials: Exploration of new materials for both face sheets and core structures, such as high-performance composites and nanoengineered materials, to further enhance the mechanical properties of corrugated sandwich panels.

- Optimized Geometries: Research into novel corrugation patterns and core geometries to maximize specific mechanical advantages for targeted applications.

- Multi-functional Panels: Development of corrugated sandwich panels that integrate additional functionalities, such as self-healing capabilities, embedded sensors, or energy harvesting features.

- Sustainable Production: Innovation in manufacturing processes to reduce the environmental impact of producing corrugated sandwich panels, including the use of recycled materials and eco-friendly bonding agents.

- Smart Structures: Integration of smart materials and adaptive technologies into corrugated sandwich panels to create structures that can respond dynamically to environmental changes or loading conditions.

Conclusion

Corrugated sandwich panels represent a significant advancement in structural engineering, offering a unique combination of mechanical advantages that make them indispensable in various industries. Their superior stiffness-to-weight ratio, enhanced load-bearing capacity, and excellent energy absorption properties set them apart from traditional materials. As we've explored, these panels find applications in construction, aerospace, transportation, and marine industries, with potential for even broader use in the future.

For those interested in harnessing the power of corrugated sandwich panels for their projects, Weifang Sandong Building Materials Co., Ltd. stands ready to provide cutting-edge solutions. As a leading corrugated sandwich panel supplier, they offer a wide range of high-quality products tailored to meet diverse needs in the construction and building materials sector. To learn more about their innovative exterior cladding and facade solutions, including corrugated sandwich panels, don't hesitate to reach out to their team of experts at info@sdqsc.com.

FAQ

What are the main components of a corrugated sandwich panel?

A corrugated sandwich panel consists of two face sheets and a corrugated core sandwiched between them. The face sheets are typically made of materials like steel or aluminum, while the core can be various materials formed into a wave-like pattern.

How do corrugated sandwich panels contribute to energy efficiency in buildings?

These panels offer excellent thermal insulation properties due to their structure, which includes air spaces within the corrugated core. This helps in maintaining desired temperatures inside buildings, reducing energy consumption for heating and cooling.

Can corrugated sandwich panels be used in renovation projects?

Yes, Weifang Sandong Building Materials Co., Ltd. offers corrugated sandwich panels suitable for various projects, including renovations of historic buildings. Their versatility makes them adaptable to different architectural styles and requirements.

References

1. Carlsson, L. A., & Kardomateas, G. A. (2011). Structural and failure mechanics of sandwich composites (Vol. 121). Springer Science & Business Media.

2. Valdevit, L., et al. (2011). Optimal active cooling performance of metallic sandwich panels with prismatic cores. International Journal of Heat and Mass Transfer, 54(21-22), 4605-4617.

3. Rejab, M. R. M., & Cantwell, W. J. (2013). The mechanical behaviour of corrugated-core sandwich panels. Composites Part B: Engineering, 47, 267-277.

4. Wadley, H. N., et al. (2003). Fabrication and structural performance of periodic cellular metal sandwich structures. Composites Science and Technology, 63(16), 2331-2343.

5. Xiong, J., et al. (2012). Sandwich panels with prismatic and hexagonal cell cores under combined in-plane compression and shear. Journal of Sandwich Structures & Materials, 14(4), 429-447.