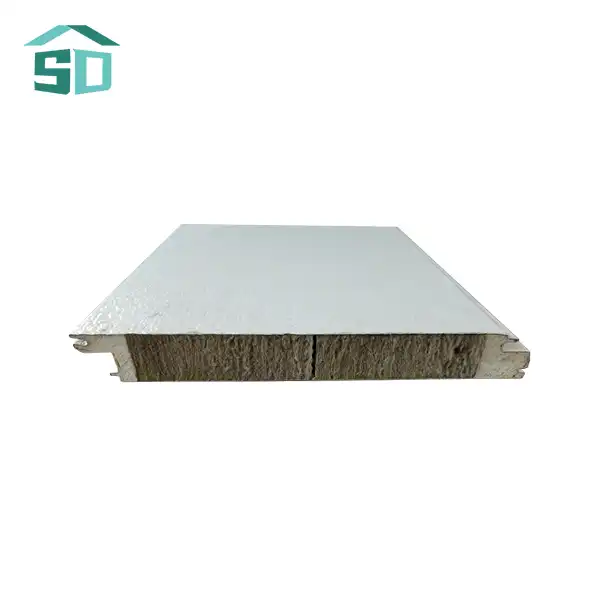

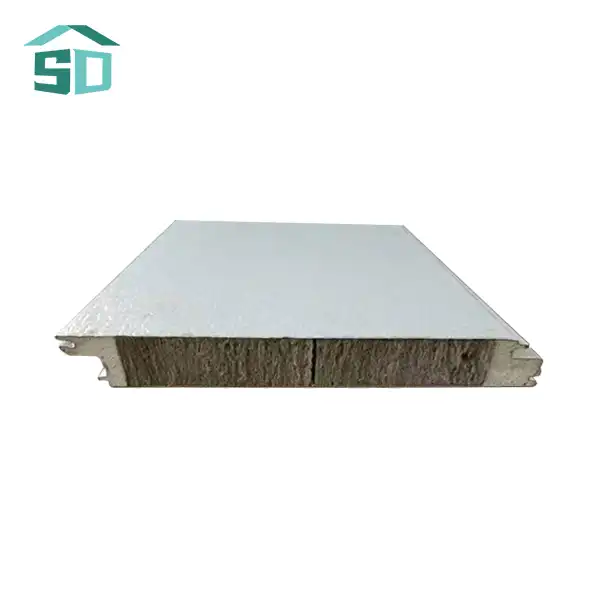

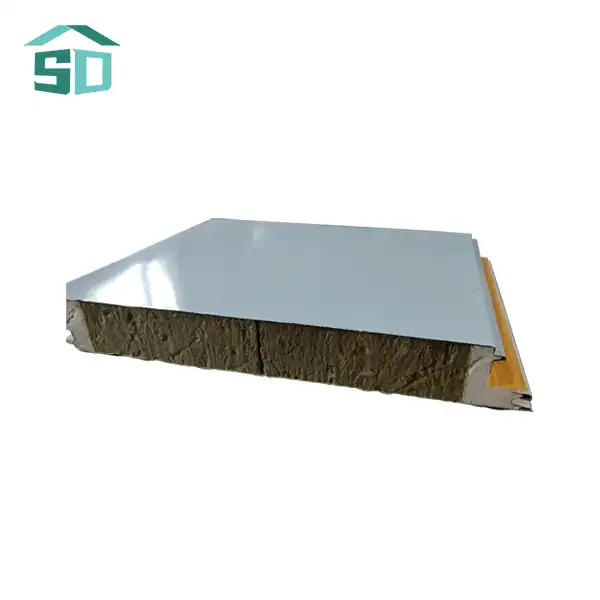

The Robust Exterior: Metal Sheet Composition and Properties

The exterior layer of metal sheet PU sandwich panels plays a crucial role in their overall performance and durability. This outer skin is typically composed of high-quality steel or aluminum, chosen for their strength, corrosion resistance, and aesthetic appeal. The metal sheet's thickness can vary, with common options ranging from 0.23mm to 0.27mm, depending on the specific requirements of the project.

Steel, a popular choice for metal sheet PU sandwich panels, offers exceptional strength and durability. It can withstand harsh environmental conditions and provides excellent protection against impact and wear. Aluminum, on the other hand, is prized for its lightweight nature and natural corrosion resistance, making it ideal for coastal or high-humidity environments.

The metal sheet's surface is often treated with protective coatings to enhance its performance further. These coatings can include galvanization for steel or anodization for aluminum, which significantly improve the material's resistance to corrosion, UV radiation, and chemical exposure. Additionally, the exterior surface can be finished with various colors and textures, allowing for customization to suit different architectural styles and preferences.

Wind Resistance and Waterproofing

The metal sheet exterior contributes significantly to the panel's wind resistance and waterproofing capabilities. With a wind resistance rating of 8.0 Kpa, these panels can withstand strong winds and adverse weather conditions. The waterproof rate of 0.0008 ensures excellent protection against moisture infiltration, preventing water damage and maintaining the integrity of the building envelope.

The Insulating Core: Polyurethane Foam Technology

At the heart of metal sheet PU sandwich panels lies the polyurethane (PU) foam core, which is responsible for the panel's exceptional insulation properties. This advanced material is created through a chemical reaction between polyol and isocyanate, resulting in a closed-cell foam structure that traps air and provides superior thermal resistance.

The PU foam core's thickness can be customized based on the specific insulation requirements of a project. For interior applications, a thickness of 10mm is often sufficient, while exterior panels may feature thicknesses of 16mm or 20mm to provide enhanced insulation for the building envelope.

Thermal Performance

The thermal conductivity of the PU foam core is an impressive 0.018W/m.k, indicating its excellent ability to resist heat transfer. This low thermal conductivity translates to a high thermal resistance of 2.09m2k/w, ensuring that the panels effectively maintain comfortable indoor temperatures while reducing energy consumption for heating and cooling.

The insulation properties of metal sheet PU sandwich panels contribute significantly to the energy efficiency of buildings. By minimizing heat loss in winter and heat gain in summer, these panels help reduce the overall energy demand of a structure, leading to lower utility costs and a smaller carbon footprint.

Fire Resistance and Safety

In expansion to its cover properties, the PU froth center moreover contributes to the fire security of metal sheet PU sandwich boards. With a fire-protection rating of B1/B2, these boards offer a great level of fire resistance, making a difference to moderate the spread of blazes in the occasion of a fire. This characteristic is vital for keeping up building security and giving inhabitants with extra time to clear in crisis circumstances.

Structural Integrity: Bonding and Compression Strength

The effectiveness of metal sheet PU sandwich panels relies heavily on the strong bond between the exterior metal sheets and the PU foam core. This bonding process is carefully controlled during manufacturing to ensure optimal adhesion and structural integrity. The result is a composite material that combines the strength of metal with the lightweight insulation properties of PU foam.

The compression strength of metal sheet PU sandwich panels is a testament to their structural capabilities. With a compressive strength of 52.7kpa, these panels can withstand significant loads without deformation or failure. This property makes them suitable for a wide range of applications, from exterior cladding to interior partitions.

Versatility in Design and Application

The uncommon combination of materials in metal sheet PU sandwich sheets licenses for remarkable adaptability in arrange and application. The sheets can be made in customized lengths to suit specific wander prerequisites. The width of exterior sheets commonly measures 383mm, though inner parts sheets are frequently made at 450mm wide, giving versatility for diverse foundation scenarios.

Architects and builders appreciate the adaptability of metal sheet PU sandwich panels for diverse construction projects. These panels find applications in residential complexes, offices, villas, gardens, historic building renovations, municipal buildings, and even security kiosks. The ability to customize colors, patterns, and finishes further enhances their appeal, allowing for seamless integration with various architectural styles and design visions.

Quality Control and Performance Assurance

To guarantee the most noteworthy quality and execution of metal sheet PU sandwich boards, producers utilize progressed generation lines and thorough quality control frameworks. Each component, from the steel coils and aluminum thwart to the polyurethane froth, experiences strict testing and comprehensive reviews. These checks incorporate appraisals of item thickness, paint film thickness, mechanical quality, fire retardancy, and generally item appearance.

This meticulous attention to quality control guarantees that metal sheet PU sandwich panels meet or exceed industry standards and project specifications. The result is a building material that offers long-lasting durability, energy efficiency, and aesthetic appeal, making it a preferred choice for modern construction projects.

Conclusion

Metal sheet PU sandwich panels represent a remarkable fusion of materials, each contributing unique properties to create a versatile and high-performance building product. From the durable metal exterior to the insulating PU foam core, these panels offer a combination of strength, energy efficiency, and design flexibility that is hard to match with traditional building materials.

As the construction industry continues to evolve, with an increasing focus on sustainability and energy efficiency, metal sheet PU sandwich panels are well-positioned to meet these demands. Their ability to enhance building performance while offering aesthetic versatility makes them an attractive option for architects, builders, and property owners alike.

For those interested in exploring the potential of metal sheet PU sandwich panels for their next construction project, or to learn more about exterior cladding and facade solutions, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your building needs, leveraging the power of advanced materials to create efficient, durable, and visually appealing structures.

References

1.Allen, E., & Iano, J. (2019). Fundamentals of Building Construction: Materials and Methods (7th ed.). Wiley.

2.Gibson, L. J., & Ashby, M. F. (1999). Cellular Solids: Structure and Properties (2nd ed.). Cambridge University Press.

3.Serrano, A., & Enfedaque, A. (2017). “Structural Performance of Sandwich Panels with Polyurethane Core.” Construction and Building Materials, 139, 145–155.

4.Zenkert, D. (1997). An Introduction to Sandwich Construction. Engineering Materials Advisory Services Ltd.

5.Al-Homoud, M. S. (2005). “Performance Characteristics and Practical Applications of Common Building Thermal Insulation Materials.” Building and Environment, 40(3), 353–366.

6.Papadopoulos, A. M. (2005). “State of the Art in Thermal Insulation Materials and Aims for Future Developments.” Energy and Buildings, 37(1), 77–86.