The Science Behind Honeycomb Sandwich Panel Strength

The extraordinary strength of honeycomb sandwich panels lies in their ingenious structure. At its core, this material utilizes the power of geometry to distribute forces evenly, maximizing strength while minimizing weight. The hexagonal cells within the core act as tiny compression members, working together to resist deformation and maintain structural integrity.

Structural Composition

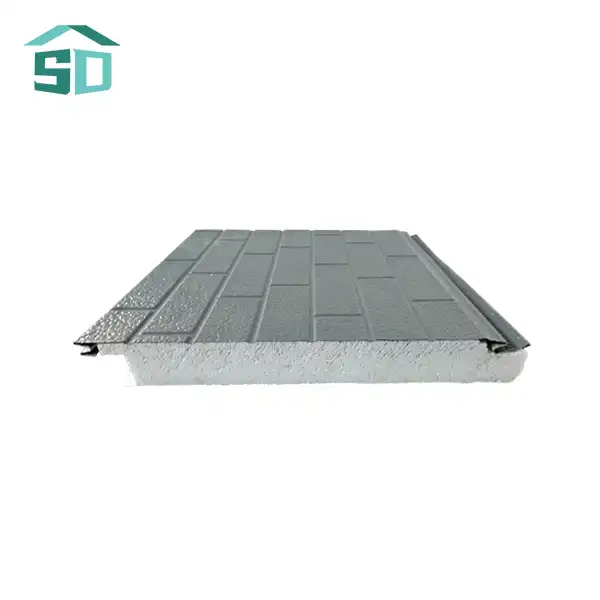

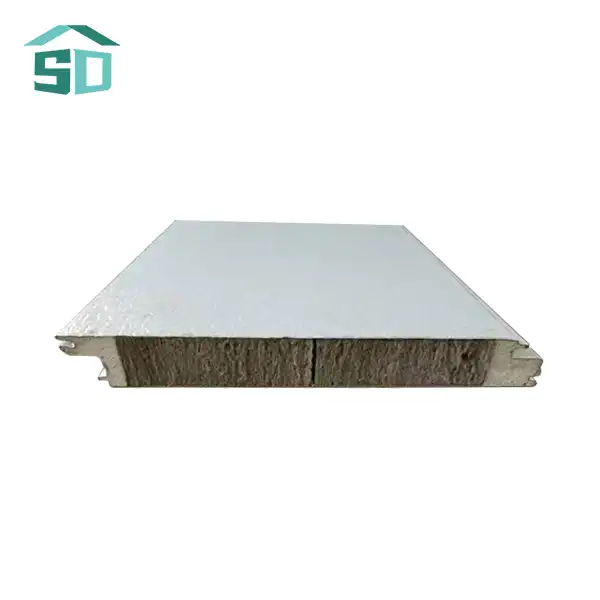

Honeycomb sandwich panels typically consist of three main components:

- Two face sheets (top and bottom layers)

- A honeycomb core

- Adhesive bonding the layers together

The face sheets are usually made of strong, rigid materials such as aluminum, steel, or fiber-reinforced composites. These outer layers provide the panel with its primary bending strength and stiffness. The honeycomb core, often made from aluminum, paper, or thermoplastics, is responsible for maintaining the separation between the face sheets and resisting shear forces.

Force Distribution

When a load is applied to a honeycomb sandwich panel, the forces are distributed across the entire structure. The face sheets work in tension and compression, while the honeycomb core resists shear and compressive forces. This synergistic interaction between components results in a panel that can withstand significant loads without buckling or deforming.

Strength-to-Weight Ratio

One of the most impressive aspects of honeycomb sandwich panels is their exceptional strength-to-weight ratio. By utilizing a lightweight core material in a geometrically efficient pattern, these panels achieve remarkable strength with minimal mass. This characteristic makes them particularly valuable in applications where weight reduction is crucial, such as aerospace and automotive industries.

Versatility and Applications of Honeycomb Sandwich Panels

The unique combination of strength, lightweight design, and versatility makes honeycomb sandwich panels suitable for a wide range of applications across various industries. From construction to transportation, these panels offer innovative solutions to complex engineering challenges.

Construction Industry

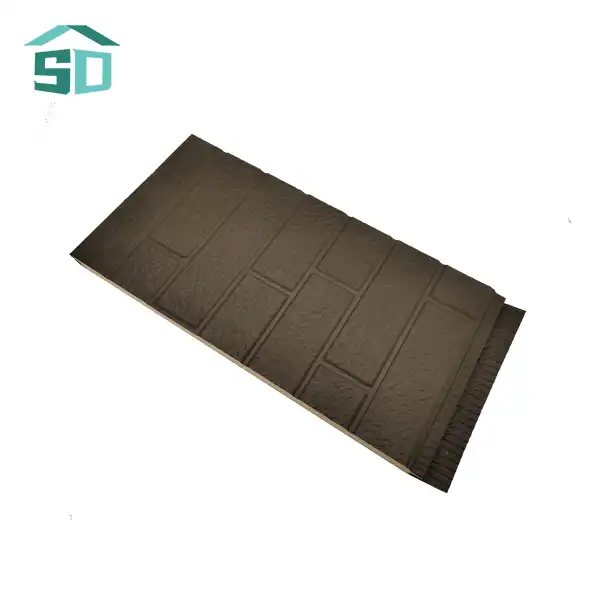

In the realm of construction, honeycomb sandwich panels have revolutionized building techniques. They are increasingly used in:

- Wall cladding and partitions

- Roofing systems

- Floor panels

- Doors and windows

The panels provide excellent thermal insulation, significantly enhancing energy efficiency in buildings by maintaining consistent indoor temperatures. Their lightweight nature not only reduces the overall load on the structure but also allows for more flexible, cost-effective design options. This combination of insulation and reduced structural weight leads to both energy savings and improved architectural versatility.

Transportation Sector

The transportation industry has embraced honeycomb sandwich panels for their weight-saving properties and strength. They are commonly used in:

- Aircraft interiors and exteriors

- Automotive body panels

- Train carriages

- Marine vessels

By reducing vehicle weight, these panels contribute to improved fuel efficiency and performance, making them a valuable asset in the pursuit of sustainable transportation solutions.

Industrial Applications

Beyond construction and transportation, honeycomb sandwich panels find applications in various industrial settings:

- Packaging and protective cases

- Clean room walls and ceilings

- Machine guards and enclosures

- Vibration damping platforms

The panels' customizable nature allows them to be tailored to specific industrial requirements, offering solutions that combine strength, lightweight design, and functionality.

Advancements and Future Prospects of Honeycomb Sandwich Panels

As technology continues to evolve, so does the potential of honeycomb sandwich panels. Researchers and engineers are constantly exploring new materials and manufacturing techniques to enhance the performance and versatility of these remarkable structures.

Material Innovations

Recent advancements in material science have led to the development of new core and face sheet materials for honeycomb sandwich panels. Some exciting innovations include:

- Nano-enhanced composites for improved strength and durability

- Bio-based materials for more sustainable panel production

- Self-healing polymers that can repair minor damage autonomously

These new materials promise to further improve the strength, longevity, and environmental friendliness of honeycomb sandwich panels.

Manufacturing Techniques

Advancements in manufacturing processes are also contributing to the evolution of honeycomb sandwich panels. Cutting-edge techniques such as:

- 3D printing of complex honeycomb structures

- Automated layup and bonding processes

- Precision core forming technologies

These innovations are enabling the production of more intricate and specialized panel designs, expanding their potential applications across industries.

Smart Panels

The integration of smart technologies into honeycomb sandwich panels represents an exciting frontier in their development. Concepts under exploration include:

- Embedded sensors for real-time structural health monitoring

- Active damping systems for improved vibration control

- Integrated energy harvesting capabilities

These smart panels could revolutionize industries by providing real-time data on structural integrity and performance, enhancing safety and efficiency across applications.

Conclusion

Honeycomb sandwich panels have proven themselves to be not just strong, but exceptionally versatile and innovative building materials. Their unique structure offers an unparalleled combination of strength, lightweight design, and adaptability, making them invaluable across a wide spectrum of industries. As advancements in materials science and manufacturing techniques continue, the potential applications for these remarkable panels are bound to expand even further.

For those seeking cutting-edge solutions in construction, transportation, or industrial applications, honeycomb sandwich panels represent a compelling choice that balances performance with efficiency. To explore how these innovative panels can benefit your next project, don't hesitate to reach out to the experts at Weifang Sandong Building Materials Co., Ltd. Contact us at info@sdqsc.com for more information on our range of honeycomb sandwich panels and other exterior cladding solutions.