Grasping the Water Resistance of Exterior Cladding Panels

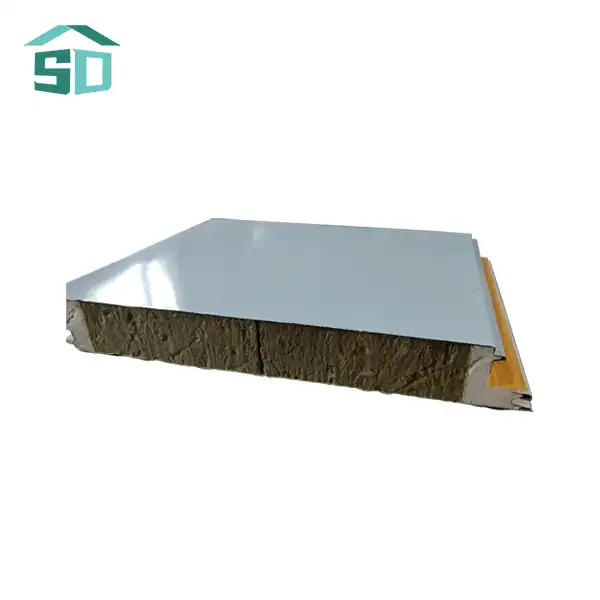

Material Composition and Its Impact on Water Resistance

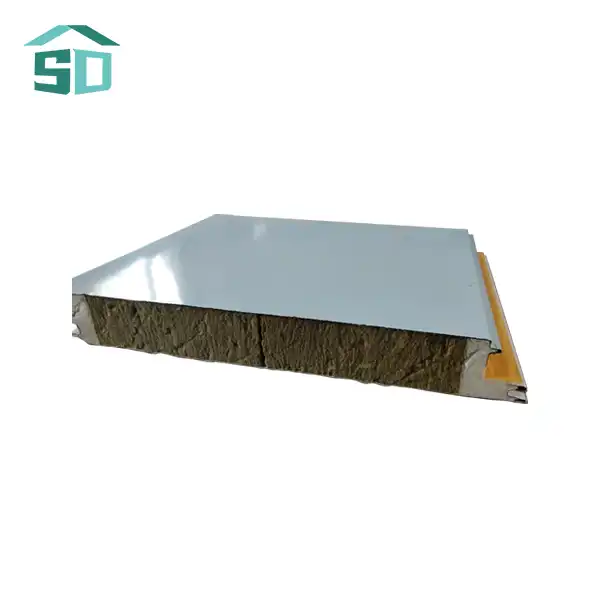

The water resistance of outside cladding boards is to a great extent decided by their fabric composition. Different materials are utilized in the fabricating of these boards, each with its claim set of properties that contribute to water resistance. Aluminum, steel, stainless steel, and copper are among the most common materials utilized for outside cladding boards. These metals naturally possess high resistance to water and corrosion, making them excellent choices for protecting buildings from moisture infiltration.

For instance, aluminum cladding panels are known for their exceptional resistance to weathering and corrosion. The natural oxide layer that forms on aluminum's surface provides an additional barrier against moisture. Steel panels, often galvanized or coated with protective layers, offer robust water resistance and durability. Stainless steel panels, with their inherent corrosion resistance, provide superior protection against water and other environmental factors. Copper cladding, while less common, develops a protective patina over time, enhancing its water-resistant properties.

The Role of Coatings and Finishes in Enhancing Water Resistance

To assist expand the water-resistant properties of outside cladding boards, producers apply specialized coatings and wraps up. These treatments not only enhance the panels' ability to repel water but also contribute to their overall durability and aesthetic appeal. Advanced coating technologies, such as fluoropolymer-based finishes, provide exceptional resistance to water, UV radiation, and chemical exposure.

The application of these high-performance coatings creates a hydrophobic surface on the exterior cladding panels, causing water to bead up and roll off rather than being absorbed. This feature is particularly beneficial in areas prone to heavy rainfall or high humidity. Additionally, these coatings often incorporate UV-resistant properties, preventing degradation of the panel surface due to prolonged sun exposure, which could otherwise compromise its water-resistant capabilities over time.

The Importance of Proper Installation for Optimal Water Resistance

While the inherent properties of the materials and coatings play a crucial role in water resistance, the installation process is equally important. Proper installation ensures that the cladding system functions as intended, maximizing its water-resistant capabilities. This involves careful attention to detail in areas such as panel alignment, sealing of joints, and the integration of flashing and drainage systems.

Experienced installers employ techniques to create a continuous barrier against water infiltration. This includes the use of appropriate sealants at panel joints, the correct installation of flashings around openings and at the base of the cladding system, and the incorporation of a drainage plane behind the panels. These measures work together to channel any water that may penetrate the outer surface away from the building structure, preventing moisture-related issues such as mold growth or structural damage.

Factors Influencing the Waterproofing Performance of Exterior Cladding Panels

Panel Design and Engineering Considerations

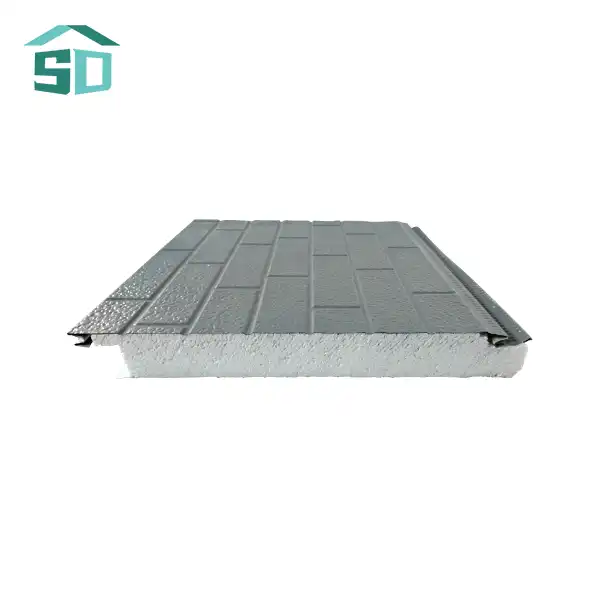

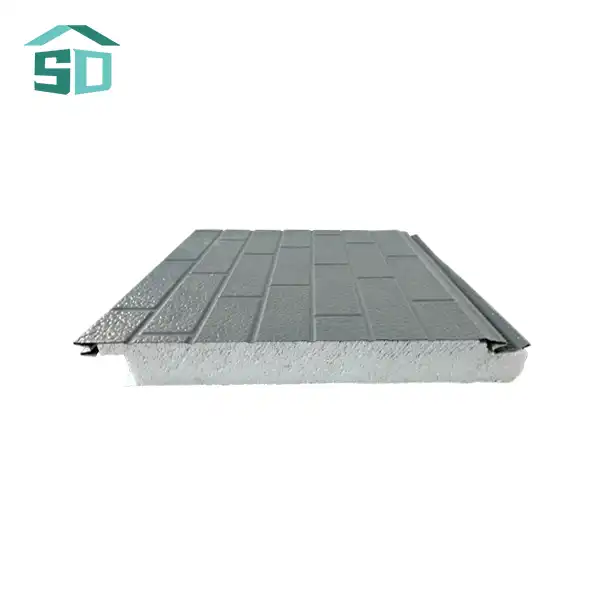

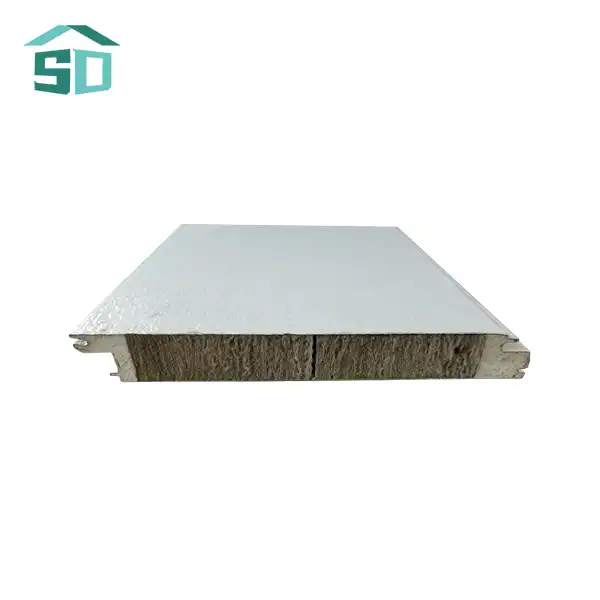

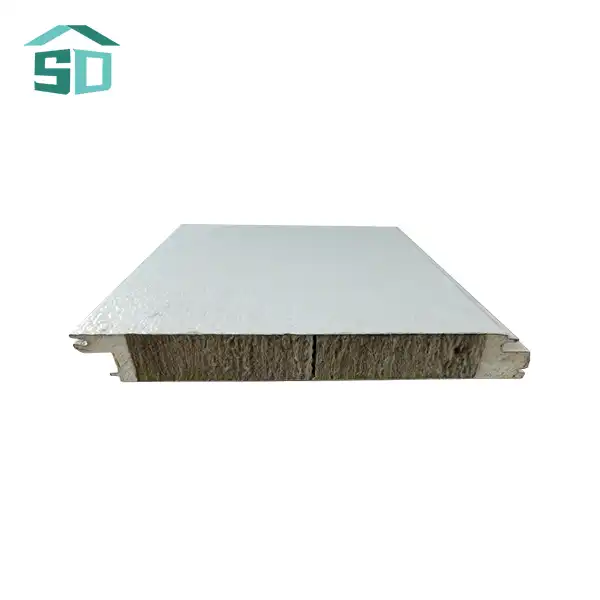

The design and engineering of exterior cladding panels play a pivotal role in their waterproofing performance. Manufacturers invest significant resources in developing panel designs that optimize water resistance while maintaining other essential properties such as thermal insulation and aesthetic appeal. The geometry of the panels, including their profile and edge details, is carefully engineered to facilitate water runoff and prevent water ingress at panel joints.

Advanced panel designs often incorporate interlocking systems or tongue-and-groove configurations that create a more effective barrier against water penetration. These designs not only enhance the water-resistant properties of the cladding system but also simplify the installation process, reducing the likelihood of errors that could compromise waterproofing performance. Additionally, some panel designs include built-in drainage channels or weep holes, allowing any moisture that does penetrate to be quickly and efficiently directed away from the building envelope.

The Impact of Environmental Conditions on Water Resistance

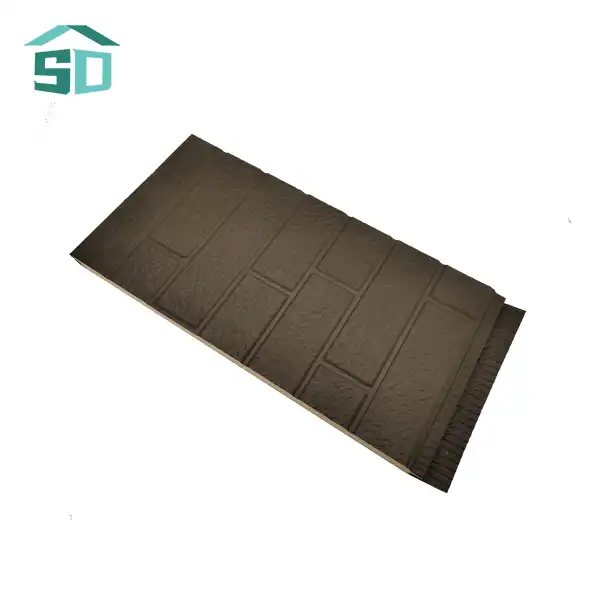

Natural conditions essentially impact the waterproofing execution of outside cladding boards over time. Components such as temperature variances, UV radiation, discuss contamination, and extraordinary climate occasions can all affect the long-term water resistance of the cladding framework. In coastal zones, for case, the combination of tall mugginess, salt splash, and solid winds can posture specific challenges to keeping up viable water resistance.

To address these environmental challenges, manufacturers develop cladding panels with specific formulations and treatments tailored to different climate zones. For instance, panels designed for tropical environments may incorporate additional UV inhibitors and anti-fungal agents to maintain their water-resistant properties in hot, humid conditions. Similarly, panels intended for use in cold climates may feature enhanced flexibility to withstand thermal expansion and contraction without compromising their water-resistant seal.

Maintenance Practices for Sustained Water Resistance

Normal upkeep is pivotal for protecting the water-resistant properties of outside cladding boards all through their life expectancy. Whereas high-quality cladding frameworks are planned to be low-maintenance, occasional assessments and cleaning are fundamental to guarantee ideal execution. Upkeep hones ordinarily incorporate expelling flotsam and jetsam from board surfaces and joints, reviewing for any signs of harm or wear, and tending to issues instantly to anticipate water invasion.

In addition to routine cleaning, periodic reapplication of protective coatings may be necessary, depending on the specific cladding material and environmental conditions. This process can help rejuvenate the water-resistant properties of the panels and extend their effective lifespan. Building owners and facility managers should follow manufacturer-recommended maintenance schedules and procedures to maximize the long-term water resistance of their cladding systems.

Advancements in Exterior Cladding Panel Technology for Enhanced Waterproofing

Innovative Materials and Composites

The field of exterior cladding panelsare witnessing rapid advancements in material science, leading to the development of innovative materials and composites with superior water-resistant properties. These new materials often combine the strengths of traditional cladding materials with cutting-edge technologies to create panels that offer unprecedented levels of water resistance and durability.

For example, some manufacturers are exploring the use of hydrophobic nanocoatings that can be applied to various cladding materials. These ultra-thin coatings create a microscopic texture on the panel surface that dramatically increases water repellency. Another area of innovation is the development of self-healing materials that can automatically repair minor cracks or damage, maintaining the integrity of the water-resistant barrier over time.

Smart Cladding Systems for Real-Time Monitoring

The integration of savvy advances into outside cladding frameworks speaks to a critical jump forward in waterproofing capabilities. These progressed frameworks consolidate sensors and observing gadgets that can distinguish dampness interruption or changes in natural conditions in real-time. By giving early caution of potential water-related issues, savvy cladding frameworks permit for proactive upkeep and fast reaction to anticipate water harm.

Some smart cladding solutions go beyond passive monitoring to include active moisture management features. These systems may incorporate automated ventilation or dehumidification mechanisms that activate in response to detected moisture levels, helping to maintain optimal conditions within the building envelope and prevent water-related problems before they escalate.

Sustainable Waterproofing Solutions

As sustainability becomes an increasingly important consideration in construction, manufacturers are developing eco-friendly waterproofing solutions for exterior cladding panels. These sustainable approaches aim to enhance water resistance while minimizing environmental impact throughout the product lifecycle.

One promising zone of advancement is the utilize of bio-based materials and coatings inferred from renewable assets. These common options can give viable water resistance without depending on petrochemical-based items. Additionally, some manufacturers are exploring ways to incorporate recycled materials into cladding panels without compromising their water-resistant properties, contributing to a more circular economy in the construction industry.

Conclusion

Exterior cladding panels, while not completely waterproof, offer a high degree of water resistance when properly designed, installed, and maintained. The combination of advanced materials, innovative coatings, and thoughtful engineering results in cladding systems that provide excellent protection against water infiltration. As technology continues to evolve, we can expect even more effective and sustainable waterproofing solutions for exterior cladding panels in the future.

For more information about our exterior cladding solutions and their water-resistant properties, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in selecting the ideal cladding system for your specific needs and environmental conditions.