The Science Behind Acoustic Performance in Insulated Sandwich Panels

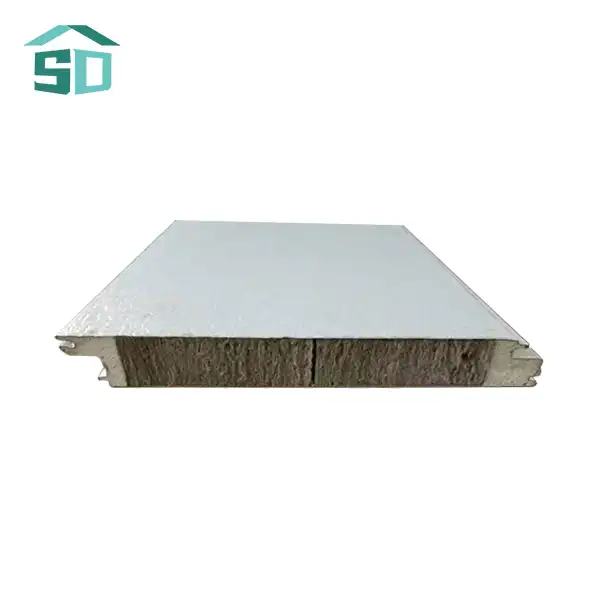

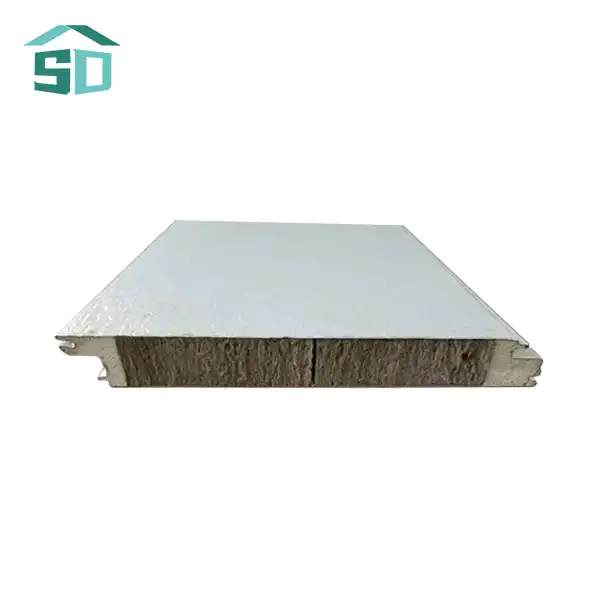

The acoustic ability of protective sandwich boards lies in their special multi-layered development. The external metal sheets, regularly made of aluminum, steel, stainless steel, or copper, act as the first line of defense against sound waves. These unbending surfaces reflect a parcel of the approaching sound vitality, lessening its concentration some time recently before it indeed comes to the cover core.

The veritable charm happens inside the center, where materials like polyurethane, polystyrene, shake downy, or glass downy work their acoustic wonders. These separator materials are especially planned to hold sound essentialness, changing it over into warmth through contact with the interior of their complex organization of strands or cells. This handle reasonably hoses sound waves, dodging them from transmitting through the board.

Sound Transmission Class (STC) Rating

The effectiveness of insulated sandwich panels in sound reduction is often measured by their Sound Transmission Class (STC) rating. This rating indicates how well a building element, such as a wall or panel, attenuates airborne sound. Higher STC ratings correspond to better sound insulation properties. Insulated sandwich panels can achieve impressive STC ratings, often ranging from 30 to 50 or even higher, depending on their thickness and composition.

Frequency-Dependent Performance

It's worth noting that the acoustic performance of insulated sandwich panels can vary across different frequencies. Generally, these panels are more effective at blocking high-frequency sounds than low-frequency ones. This characteristic makes them particularly useful in industrial settings where machinery often produces high-pitched noises that can be especially disruptive and potentially harmful to workers' hearing.

Customization and Versatility: Tailoring Acoustic Solutions

One of the most compelling aspects of insulated sandwich panels is their adaptability to various acoustic challenges. Manufacturers like Weifang Sandong Building Materials Co., Ltd. offer a range of customization options to meet specific project requirements.

Thickness Variations

The thickness of insulated sandwich panels significantly influences their ability to block or absorb sound. Available in a range of 50mm to 150mm, thicker panels tend to offer enhanced sound insulation by reducing the transmission of airborne noise. This variation in thickness provides architects and engineers with valuable flexibility, allowing them to tailor acoustic performance to the unique requirements of each project, whether in manufacturing plants, auditoriums, or commercial buildings.

Core Material Selection

The core material within a sandwich panel is a key determinant of its acoustic behavior. Rock wool, for instance, is highly porous and excels in absorbing sound waves, making it ideal for environments with high ambient noise, such as factories or concert halls. Polyurethane, by contrast, provides a balanced solution, offering both effective thermal insulation and moderate acoustic performance—well-suited to mixed-use spaces where temperature and noise control are both priorities.

Surface Treatments

In addition to structural and thermal considerations, the surface finish of insulated sandwich panels plays a subtle yet important role in acoustic performance. Coatings, paint systems, or anodized finishes can influence how sound waves reflect or dissipate on the panel’s surface. Though often chosen for visual appeal or corrosion resistance, these treatments can help optimize the acoustic behavior of the panels, especially in environments where echo control and sound clarity are critical.

Beyond Acoustics: The Multifaceted Benefits of Insulated Sandwich Panels

While their acoustic properties are impressive, insulated sandwich panels offer a host of additional benefits that make them a superior choice for industrial and commercial applications.

Thermal Efficiency

Insulated sandwich panels offer excellent thermal resistance thanks to their low-conductivity cores and tight-sealing design. By minimizing heat transfer through walls and ceilings, they reduce dependency on heating and cooling systems, promoting consistent indoor comfort. This translates to lower energy consumption, which is not only cost-effective but also aligns with green building initiatives. As a result, these panels contribute meaningfully to a building's overall energy performance and environmental sustainability.

Fire Safety

Modern insulated sandwich panels are often engineered to comply with rigorous fire safety standards. Many utilize non-combustible core materials like mineral wool and feature fire-retardant coatings on the metal facings. These enhancements ensure that the panels do not easily ignite or propagate flames, thereby improving occupant safety. Especially in settings like warehouses or chemical facilities, where fire hazards are heightened, such panels provide an added layer of critical protection.

Durability and Low Maintenance

Constructed with high-strength metal facings and resilient core materials, insulated sandwich panels are designed for longevity. Their resistance to corrosion, UV exposure, and mechanical impact allows them to perform reliably in harsh environments, from coastal areas to heavy industrial zones. Additionally, the smooth outer surfaces are easy to clean and resistant to dirt buildup, minimizing maintenance efforts and extending the visual and functional lifespan of the structure.

Quick Installation

One of the most practical advantages of insulated sandwich panels is their ease of installation. The prefabricated, modular design allows for quick alignment and secure fastening, which accelerates construction timelines considerably. This efficiency reduces the need for extensive labor or complex supporting structures, ultimately saving time and money. In fast-paced projects or emergency builds, the speed of panel installation becomes a major logistical and financial benefit.

Conclusion

In conclusion, insulated sandwich panels represent a revolutionary approach to addressing the acoustic challenges in industrial environments. Their ability to effectively reduce noise transmission, combined with their thermal efficiency, fire safety features, and durability, makes them an invaluable asset in modern construction. As industries continue to prioritize worker comfort and productivity, these silent guardians stand ready to create quieter, more comfortable, and more efficient workspaces. For those seeking to enhance their industrial acoustics and overall building performance, exploring the possibilities offered by insulated sandwich panels is a sound investment in every sense of the word.

If you're interested in learning more about how insulated sandwich panels can transform your industrial or commercial space, we invite you to reach out to our team of experts at Weifang Sandong Building Materials Co., Ltd. Contact us at info@sdqsc.com to discuss your specific needs and discover tailored solutions that can make a real difference in your building's performance and comfort.