Understanding the Corrosion-Resistant Properties of Black Metal Siding Panels

Black metal siding panels have gained popularity in modern architecture for their sleek appearance and durability. These panels are not just aesthetically pleasing; they also offer superior corrosion resistance when properly manufactured and treated. The key to their rust-resistant properties lies in the materials used and the surface treatments applied.

Materials That Make a Difference

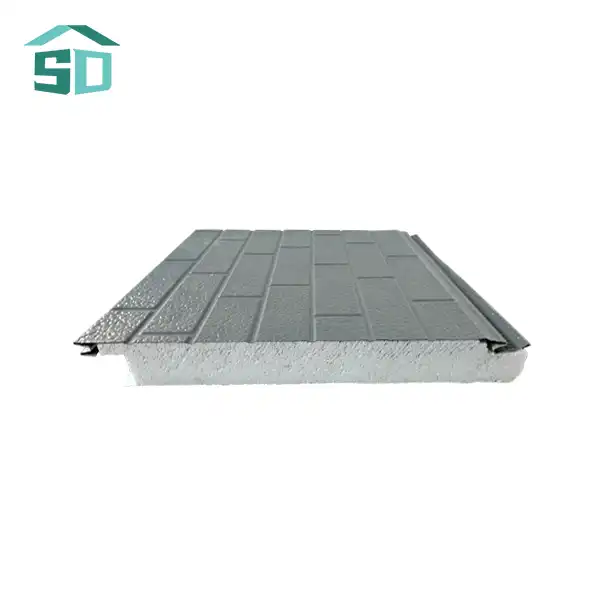

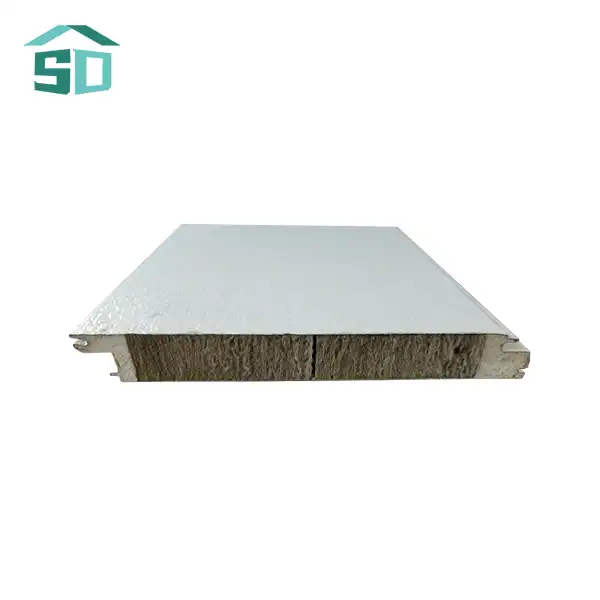

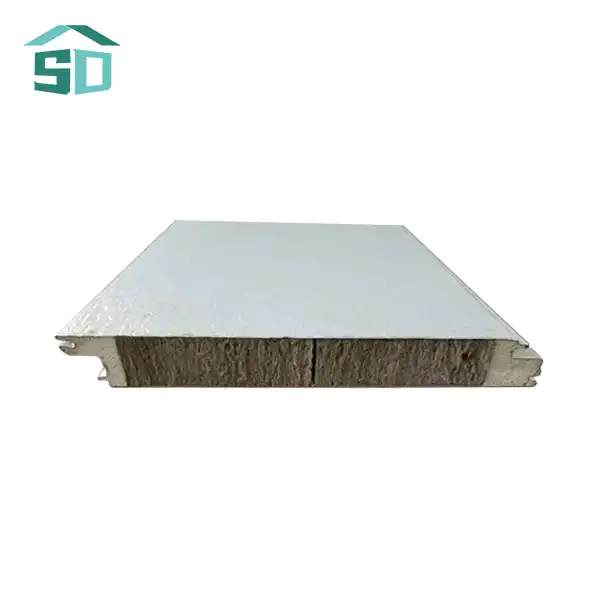

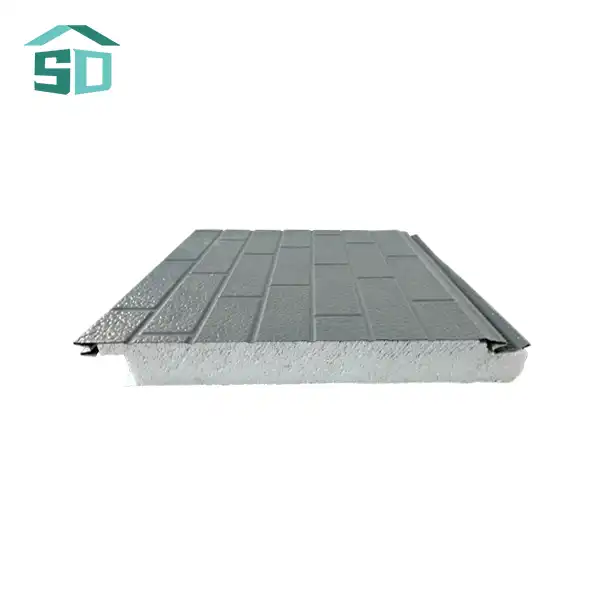

When it comes to black metal siding panels, the choice of base material is crucial. Galvanized steel and aluminum are two of the most common materials used due to their inherent resistance to corrosion. Galvanized steel is coated with a layer of zinc, which acts as a sacrificial anode, protecting the underlying steel from rust. Aluminum, on the other hand, naturally forms a thin oxide layer when exposed to air, providing a barrier against corrosion.

Surface Treatments for Enhanced Protection

To further enhance the corrosion resistance of black metal siding panels, various surface treatments are applied. Powder coating is a popular choice, offering a durable and attractive finish that resists chipping, fading, and corrosion. Anodizing is another effective treatment, particularly for aluminum panels, creating a hard, porous surface that can be sealed for additional protection.

These treatments not only provide a barrier against moisture and other corrosive elements but also contribute to the panels' aesthetic appeal. The sleek black finish adds a modern touch to any building facade while ensuring long-lasting performance in various environmental conditions.

Preventive Measures to Protect Black Metal Siding Panels from Rust

While black metal siding panels are designed to be corrosion-resistant, taking preventive measures can significantly extend their lifespan and maintain their appearance. Here are some effective strategies to keep your metal siding panels rust-free:

Regular Cleaning and Maintenance

One of the simplest yet most effective ways to prevent rust is through regular cleaning. Debris, dirt, and pollutants can accumulate on the surface of metal siding panels, potentially leading to corrosion if left unchecked. Use a soft brush or cloth with mild soap and water to clean the panels periodically. Avoid abrasive materials or harsh chemicals that could damage the protective coating.

Proper Installation and Ventilation

Ensuring proper installation is crucial in preventing rust. Black metal siding panels should be installed with appropriate gaps and overlaps to allow for expansion and contraction due to temperature changes. Adequate ventilation behind the panels is also essential to prevent moisture buildup, which can lead to corrosion. Work with experienced professionals who understand the specific requirements for installing metal siding panels.

Addressing Damage Promptly

Regular inspections can help identify any scratches, dents, or other damage to the panels. These areas can be vulnerable to rust if left unaddressed. Small scratches can often be repaired with touch-up paint designed for metal siding. For more significant damage, consult with a professional to determine the best course of action.

Advanced Solutions for Long-Term Rust Prevention

For those seeking additional protection or dealing with particularly challenging environments, there are advanced solutions available to prevent rust on black metal siding panels:

Specialized Coatings and Sealants

In addition to standard surface treatments, specialized coatings and sealants can provide an extra layer of protection against rust. These products are designed to bond with the metal surface, creating a robust barrier against moisture and other corrosive elements. Some coatings even offer self-healing properties, further enhancing their protective capabilities.

Cathodic Protection Systems

For metal siding panels in highly corrosive environments, such as coastal areas, cathodic protection systems can be an effective solution. These systems use sacrificial anodes or impressed current to protect the metal from corrosion, essentially creating an electrochemical cell that prevents rust formation.

Environmental Control Measures

In some cases, controlling the environment around the black metal siding panels can help prevent rust. This might involve improving drainage around the building to reduce moisture exposure or installing barriers to protect against salt spray in coastal areas. While these measures may require additional investment, they can significantly extend the life of your metal siding panels.

By implementing these advanced solutions, property owners can ensure that their black metal siding panels remain rust-free and maintain their aesthetic appeal for many years, even in challenging environments.

Conclusion

Preventing rust on black metal siding panels is a multifaceted approach that combines quality materials, proper installation, regular maintenance, and, when necessary, advanced protective measures. By understanding the corrosion-resistant properties of these panels and taking proactive steps to protect them, you can ensure that your building's exterior remains attractive and durable for years to come.

Whether you're considering black metal siding panels for a new construction project or looking to maintain existing panels, it's crucial to work with experienced professionals who understand the unique properties and requirements of these materials. For expert advice on selecting, installing, and maintaining black metal siding panels, don't hesitate to reach out to us at info@sdqsc.com. Our team is dedicated to providing high-quality exterior cladding solutions that meet your aesthetic and performance needs.