Understanding Metal Insulated Sandwich Panels

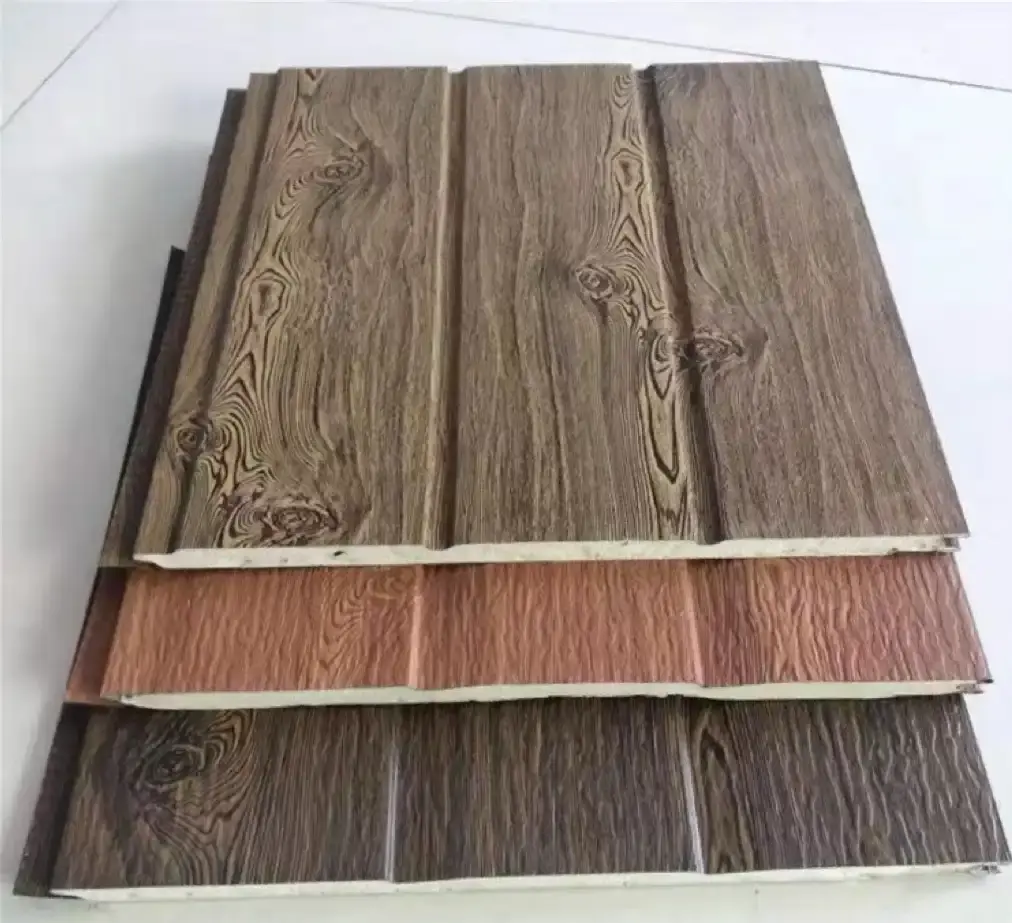

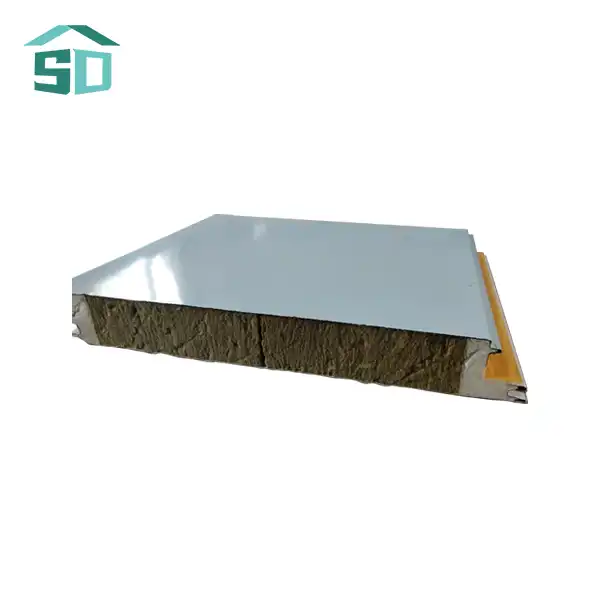

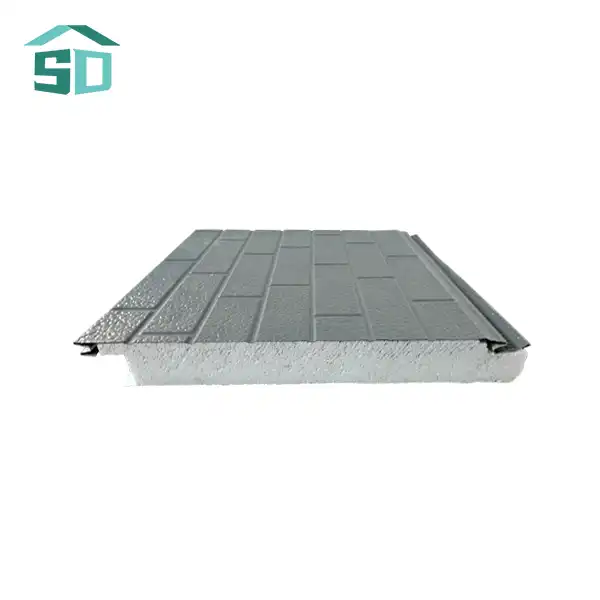

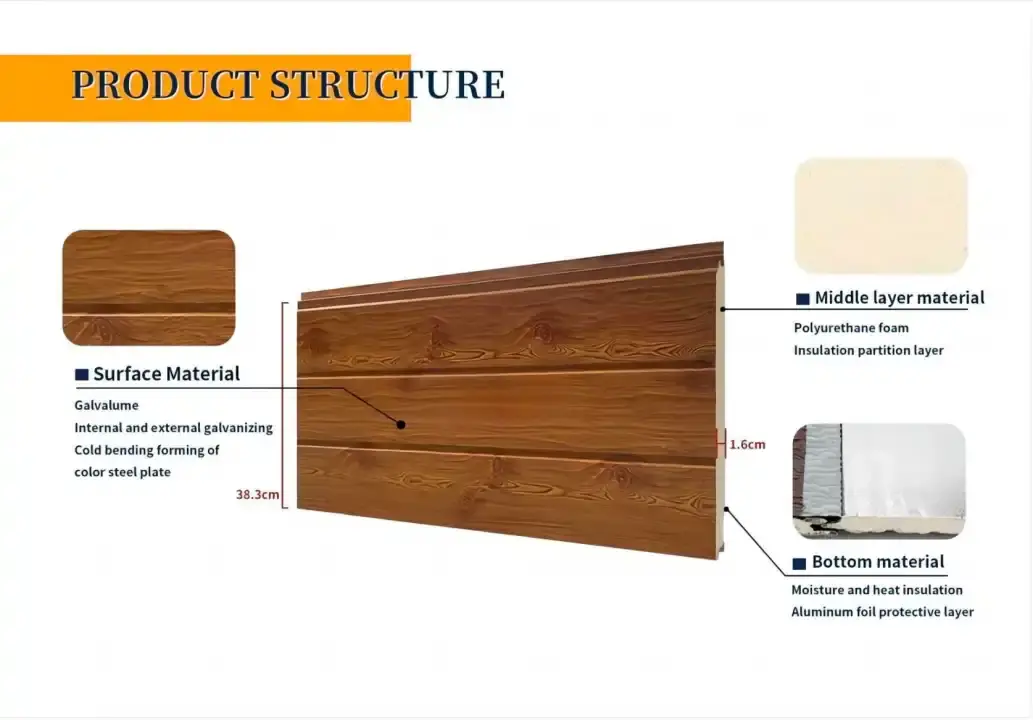

Before delving into the installation process, it's crucial to grasp the fundamentals of metal insulated sandwich panels. These innovative components consist of two metal facings enclosing a core of insulating material, typically polyurethane foam or mineral wool. This composition results in a lightweight yet robust panel that provides superior thermal insulation, fire resistance, and structural integrity.

Key Features of Metal Insulated Sandwich Panels

Metal insulated sandwich panels boast an array of impressive features that make them a top choice for modern construction projects:

- Exceptional thermal insulation properties

- High fire resistance ratings

- Excellent acoustic performance

- Remarkable durability and longevity

- Versatile design options

- Quick and easy installation

- Cost-effective building solution

These attributes contribute to the growing popularity of metal insulated sandwich panels among architects, builders, and property owners alike.

Applications of Metal Insulated Sandwich Panels

The versatility of metal insulated sandwich panels allows for their use in a wide range of construction projects, including:

- Commercial and industrial buildings

- Warehouses and storage facilities

- Cold storage and food processing plants

- Retail spaces and showrooms

- Educational institutions

- Healthcare facilities

- Residential structures

Regardless of the application, proper installation is key to maximizing the benefits of metal insulated sandwich panels.

Preparing for Installation

Successful installation of metal insulated sandwich panels begins with thorough preparation. This phase ensures that you have all the necessary materials, tools, and information to proceed smoothly.

Essential Tools and Materials

Gather the following tools and materials before commencing the installation of metal insulated sandwich panels:

- Metal insulated sandwich panels

- Fasteners (screws, bolts, or rivets)

- Sealant and caulking gun

- Measuring tape and chalk line

- Power drill with appropriate bits

- Circular saw with metal-cutting blade

- Safety equipment (gloves, goggles, hard hat)

- Scaffolding or lift equipment

- Level and plumb bob

Site Preparation

Before installing metal insulated sandwich panels, ensure the site is properly prepared:

- Inspect the structural support system for any defects or damage

- Verify that all surfaces are clean, dry, and free of debris

- Check that the support structure is level and plumb

- Review local building codes and regulations

- Obtain necessary permits and approvals

Panel Layout Planning

Careful planning of the panel layout is crucial for achieving optimal results:

- Create a detailed layout plan, considering panel sizes and orientations

- Account for openings such as windows, doors, and vents

- Plan for proper overlap and sealing between panels

- Consider the visual impact of panel joints and alignments

Step-by-Step Installation Process

With proper preparation complete, you can proceed with the installation of metal insulated sandwich panels. Follow these steps for a successful installation:

Step 1: Establishing a Starting Point

Begin by establishing a level starting point for your metal insulated sandwich panels:

- Use a chalk line to mark a straight, level line along the base of the wall

- Install a starter track or base channel along this line

- Ensure the starter track is securely fastened and level

Step 2: Installing the First Panel

Carefully position and secure the first metal insulated sandwich panel:

- Place the panel in the starter track, ensuring it's plumb and level

- Secure the panel to the structural supports using appropriate fasteners

- Follow the manufacturer's recommendations for fastener type and spacing

- Apply sealant to the panel edges as specified

Step 3: Continuing Panel Installation

Progress with the installation of subsequent metal insulated sandwich panels:

- Align each panel with the previous one, ensuring proper interlocking

- Maintain consistent joint spacing and alignment

- Secure panels to the structural supports as you go

- Apply sealant to panel joints and connections

- Regularly check for plumbness and levelness

Step 4: Cutting and Fitting Panels

Modify panels as necessary to accommodate openings and obstacles:

- Measure and mark panels accurately before cutting

- Use appropriate cutting tools, such as a circular saw with a metal-cutting blade

- Ensure clean, precise cuts to maintain panel integrity

- Seal cut edges to prevent moisture ingress

Step 5: Installing Flashings and Trims

Complete the installation with proper flashings and trims:

- Install corner flashings, window and door trims, and other accessories

- Ensure proper overlap and sealing to prevent water infiltration

- Secure flashings and trims according to manufacturer specifications

Step 6: Final Inspection and Clean-up

Conclude the installation process with a thorough inspection:

- Check all panel connections and seals for proper installation

- Verify that all fasteners are secure and properly seated

- Clean the panel surfaces, removing any debris or excess sealant

- Address any issues or imperfections identified during the inspection

Conclusion

Installing metal insulated sandwich panels is a precise process that requires careful planning and execution. By following these step-by-step instructions, you can ensure a successful installation that maximizes the benefits of these innovative building materials. Remember to prioritize safety, adhere to manufacturer guidelines, and comply with local building codes throughout the installation process. With proper installation, metal insulated sandwich panels will provide long-lasting performance, energy efficiency, and aesthetic appeal to your building project.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing top-quality metal insulated sandwich panels and expert guidance for your construction needs. Our panels offer unmatched thermal insulation, fire resistance, and design flexibility, making them the perfect choice for both new construction and renovation projects. Whether you're working on a commercial facility, residential complex, or industrial building, our metal insulated sandwich panels deliver exceptional performance and durability. Experience the difference of our advanced building solutions and elevate your next project to new heights. For more information or to discuss your specific requirements, please contact us at info@sdqsc.com.

FAQs

What are the main advantages of using metal insulated sandwich panels?

Metal insulated sandwich panels offer excellent thermal insulation, fire resistance, durability, and quick installation. They are versatile, energy-efficient, and suitable for various applications.

How long do metal insulated sandwich panels typically last?

With proper installation and maintenance, metal insulated sandwich panels can last 30-50 years or more, depending on environmental conditions and usage.

Can metal insulated sandwich panels be used for both walls and roofs?

Yes, these panels are designed for use in both wall and roof applications, providing a comprehensive building envelope solution.

Are metal insulated sandwich panels environmentally friendly?

Many metal insulated sandwich panels are eco-friendly, using recyclable materials and contributing to energy efficiency in buildings.

How do I choose the right metal insulated sandwich panel supplier?

Look for suppliers with a proven track record, quality certifications, and a wide range of products. Weifang Sandong Building Materials Co., Ltd. is a reputable choice for high-quality metal insulated sandwich panels.

References

1. Architectural Institute of America. (2022). "Sustainable Design and Building Materials." AIA Press.

2. International Building Code. (2021). "Chapter 26: Plastic." International Code Council.

3. National Fire Protection Association. (2023). "NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components." NFPA.

4. U.S. Department of Energy. (2022). "Building Envelope Design Guide." Office of Energy Efficiency & Renewable Energy.

5. World Green Building Council. (2023). "Bringing Embodied Carbon Upfront." WorldGBC.