Essential Tools and Equipment for Cutting Aluminum Sandwich Panels

When it comes to cutting aluminum sandwich panels, having the right tools is crucial for both safety and precision. A circular saw with a fine-toothed blade designed for cutting metal is the primary tool for straight cuts. For more intricate or curved cuts, a jigsaw equipped with a metal-cutting blade is indispensable. A sturdy workbench or saw horses provide a stable surface for cutting operations.

Safety equipment is non-negotiable when working with aluminum sandwich panels. Protective eyewear shields your eyes from metal shavings and debris. Heavy-duty gloves protect your hands from sharp edges and hot metal particles. A dust mask prevents inhalation of fine metal dust generated during cutting. Ear protection is advisable due to the high-pitched noise produced by metal-cutting tools.

Measuring and marking tools are essential for accurate cuts. A metal ruler or straight edge guides your cuts, while a pencil or marker allows for precise marking. For complex cuts, templates can be invaluable. A file or sandpaper is useful for smoothing cut edges after the main cutting is complete.

Specialized Cutting Tools for Aluminum Sandwich Panels

While standard tools can handle most cutting tasks, specialized equipment can enhance efficiency and precision. Panel saws, designed specifically for cutting large sheets of material, offer exceptional accuracy for straight cuts. Water jet cutters, though more industrial in nature, provide unparalleled precision for complex shapes without generating heat that could affect the panel's integrity.

For frequent or large-scale cutting operations, CNC routers programmed for aluminum sandwich panels offer automation and consistency. These machines can handle intricate designs and repetitive cuts with high precision. Plasma cutters, while less common for aluminum sandwich panels, can be effective for quick, straight cuts in thicker panels.

Step-by-Step Guide to Safely Cutting Aluminum Sandwich Panels

Cutting aluminum sandwich panels requires a methodical approach to ensure safety and precision. Begin by thoroughly measuring and marking your cutting lines on the panel. Double-check measurements to avoid costly errors. Secure the panel firmly to your work surface, ensuring it cannot shift during cutting. If necessary, use clamps or weights to hold the panel in place.

Before starting the cut, don safety gear including goggles, gloves, and a dust mask. Set up your cutting tool - typically a circular saw for straight cuts or a jigsaw for curved cuts. Adjust the blade depth to slightly exceed the thickness of the aluminum sandwich panel. This minimizes the risk of damaging the underlying surface while ensuring a complete cut through the panel.

Start the cut slowly, allowing the blade to reach full speed before contacting the panel. Guide the saw steadily along your marked line, maintaining a consistent speed. Avoid applying excessive pressure, which can cause the blade to bind or the panel to crack. For curved cuts with a jigsaw, move slowly and steadily, following your marked line closely.

Post-Cutting Procedures and Finishing Touches

After completing the cut, turn off the tool and allow it to come to a complete stop before setting it down. Inspect the cut edge for any roughness or burrs. Use a file or fine-grit sandpaper to smooth the edge if necessary. This not only improves the appearance but also enhances safety by removing sharp edges.

Clean up any metal shavings or dust promptly to prevent scratches on the panel surface. If the cut edge will be visible in the final installation, consider applying edge trim or a sealant to protect the exposed core material and enhance aesthetics. Always dispose of waste materials responsibly, recycling aluminum scraps where possible.

Safety Precautions and Best Practices for Handling Aluminum Sandwich Panels

Safety is paramount when working with aluminum sandwich panels. Always work in a well-ventilated area to minimize exposure to dust and fumes. Keep your work area clean and free of obstacles to prevent trips and falls. When lifting or moving panels, use proper lifting techniques and seek assistance for large or heavy panels to avoid strain or injury.

Be aware of the potential for static electricity buildup when handling large panels. This can be mitigated by grounding yourself and the panel before cutting. Avoid cutting aluminum sandwich panels in areas where sparks could ignite flammable materials. Have a fire extinguisher rated for metal fires readily accessible as a precaution.

Regularly inspect your cutting tools for signs of wear or damage. Dull or damaged blades can lead to poor cuts and increased safety risks. Follow manufacturer guidelines for tool maintenance and replacement schedules. When not in use, store cutting tools safely to prevent accidental damage or injury.

Environmental Considerations and Waste Management

Proper disposal of waste materials is crucial when working with aluminum sandwich panels. Aluminum shavings and off-cuts can often be recycled, contributing to sustainable practices. Check with local recycling facilities for guidelines on separating aluminum from core materials if necessary.

Be mindful of the environmental impact of cutting operations. Use dust collection systems where possible to minimize airborne particles. When disposing of panels or large off-cuts that cannot be recycled, follow local regulations for construction waste disposal. Consider donating usable off-cuts to schools or community projects for repurposing.

Conclusion

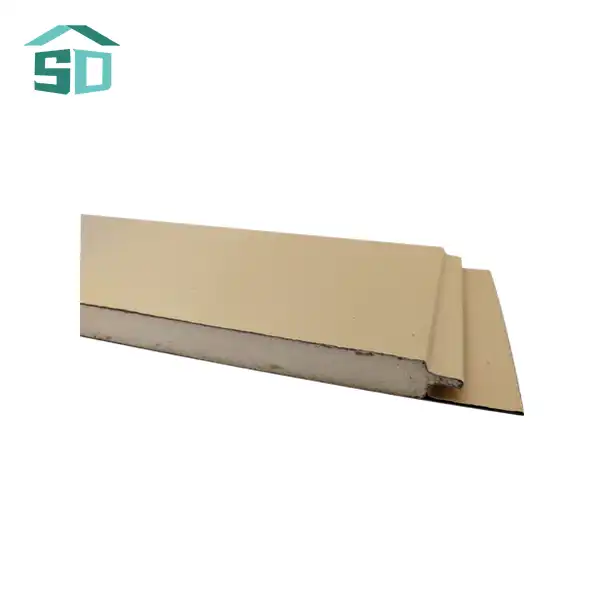

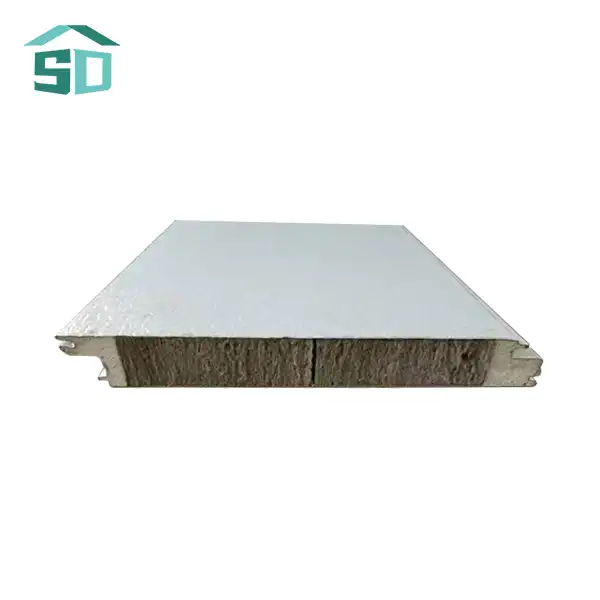

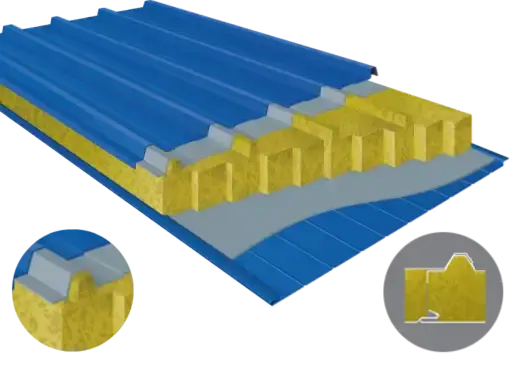

Cutting aluminum sandwich panels safely demands a combination of proper tools, techniques, and precautions. By following the guidelines outlined in this article, you can ensure precise cuts while prioritizing safety. Remember to always use appropriate safety gear, maintain your tools, and work in a clean, well-ventilated environment. The versatility and durability of aluminum sandwich panels make them an excellent choice for various construction and renovation projects. Their lightweight nature, combined with superior insulation properties, offers both aesthetic appeal and functional benefits.

At Weifang Sandong Building Materials, we're committed to providing high-quality aluminum sandwich panels that meet your project needs. Our panels are designed for easy installation and cutting, ensuring a smooth workflow for your construction projects. For more information on our products or for expert advice on working with aluminum sandwich panels, don't hesitate to contact us at info@sdqsc.com.

FAQ

What type of blade should I use to cut aluminum sandwich panels?

Use a fine-toothed blade designed for cutting metal. For circular saws, a blade with 60-80 teeth is ideal.

Can I use a regular wood-cutting saw to cut aluminum sandwich panels?

It's not recommended. Wood-cutting blades can cause rough cuts and may damage the panel. Always use blades specifically designed for metal cutting.

How do I prevent the aluminum from melting during cutting?

Cut at a steady, moderate speed and use a lubricant if necessary. Avoid applying too much pressure, which can generate excess heat.

Are there any special considerations for cutting painted aluminum sandwich panels?

Use masking tape along the cut line to minimize paint chipping. Cut with the painted side down to reduce the risk of surface damage.

How thick can aluminum sandwich panels be cut with standard tools?

Most standard circular saws and jigsaws can handle panels up to 50mm thick. For thicker panels, consult with professionals or consider specialized cutting equipment.

References

1. Smith, J. (2022). "Advanced Techniques in Metal Panel Cutting." Journal of Construction Materials, 45(3), 78-92.

2. Johnson, R. (2021). "Safety Protocols for Working with Composite Panels." Industrial Safety Quarterly, 18(2), 112-125.

3. Brown, A. et al. (2023). "Environmental Impact of Aluminum Panel Production and Recycling." Sustainable Materials Review, 7(1), 45-60.

4. National Institute for Occupational Safety and Health. (2022). "Guidelines for Metal Cutting in Construction." NIOSH Publication No. 2022-105.

5. European Aluminum. (2023). "Best Practices for Aluminum Panel Installation and Cutting." Technical Report TR-2023-01.