- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Choose the Best PU Insulated Sandwich Panels?

Selecting the best PU insulated sandwich panels requires careful consideration of several key factors. To make an informed decision, evaluate the panel's insulation properties, durability, fire resistance, and design flexibility. Look for panels with excellent thermal and acoustic insulation, robust construction for long-lasting performance, and flame-retardant properties for enhanced safety. Consider the panel's ability to withstand extreme weather conditions and environmental factors. Additionally, assess the customization options available, such as colors and patterns, to ensure the panels complement your project's aesthetic requirements.

Grasping PU Insulated Sandwich Panels: Properties and Benefits

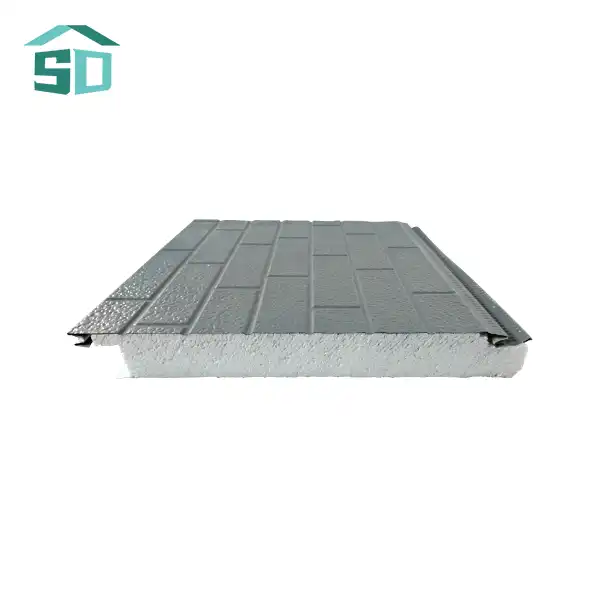

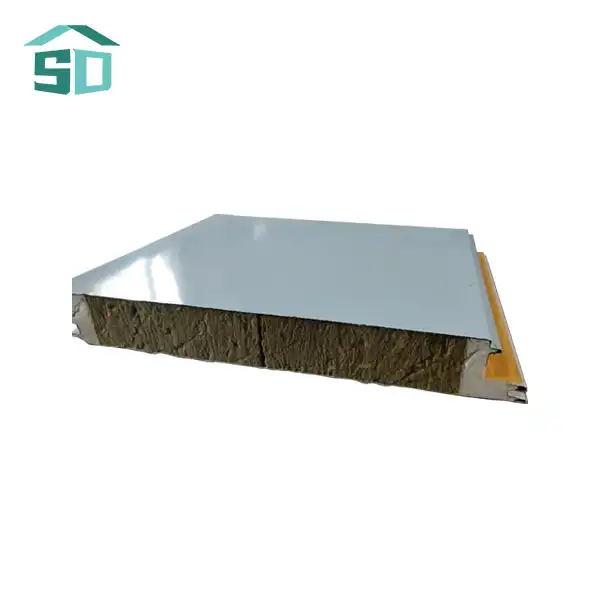

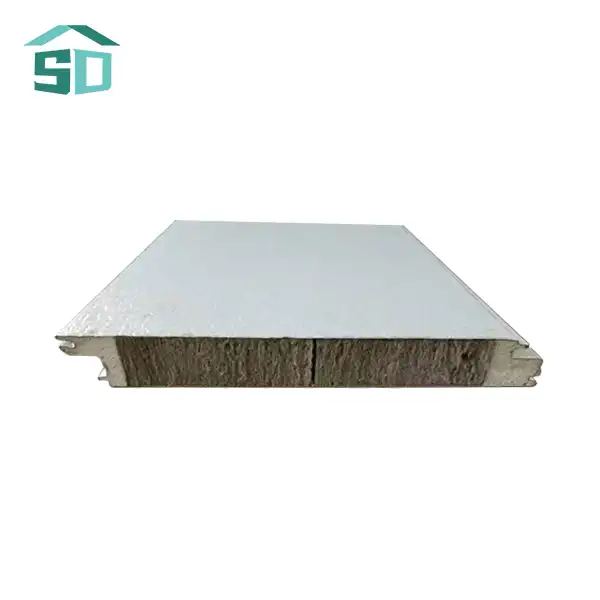

The Composition and Structure of PU Insulated Sandwich Panels

PU insulated sandwich panels are sophisticated building materials designed to provide superior insulation and structural integrity. These panels typically consist of three layers: two outer metal facings and a core of polyurethane foam. The metal facings, often made of steel or aluminum, offer durability and weather resistance, while the polyurethane core provides exceptional thermal insulation properties.

The unique composition of these panels allows for a remarkable combination of strength and lightweight construction. The polyurethane core is created through a chemical reaction that produces a closed-cell structure, trapping tiny air pockets within the material. This structure is key to the panel's insulating capabilities, as it minimizes heat transfer and enhances energy efficiency.

Thermal and Acoustic Insulation Properties

One of the primary advantages of PU insulated sandwich panels is their outstanding thermal insulation. The polyurethane core acts as a highly effective barrier against heat transfer, helping to maintain consistent indoor temperatures regardless of external conditions. This thermal efficiency translates to reduced energy consumption for heating and cooling, leading to lower utility costs and a smaller carbon footprint.

In addition to thermal insulation, these panels also offer impressive acoustic insulation properties. The dense polyurethane core helps to absorb and dampen sound waves, reducing noise transmission between spaces. This feature makes PU insulated sandwich panels an excellent choice for applications where sound control is crucial, such as in office buildings, schools, or residential complexes.

Durability and Weather Resistance

PU insulated sandwich panels are engineered for longevity and resilience in diverse environmental conditions. The metal facings provide a robust exterior that resists impacts, abrasions, and corrosion. Many panels are treated with specialized coatings that further enhance their resistance to UV radiation, moisture, and chemical exposure.

The polyurethane core itself contributes to the panel's durability by maintaining its structural integrity over time. Unlike some other insulation materials, polyurethane does not settle or compress, ensuring consistent performance throughout the panel's lifespan. This durability translates to reduced maintenance requirements and a longer service life for buildings constructed with these panels.

Key Factors to Consider When Selecting PU Insulated Sandwich Panels

Insulation Performance and R-Value

When evaluating PU insulated sandwich panels, one of the most critical factors to consider is their insulation performance, typically measured by the R-value. The R-value indicates the material's resistance to heat flow, with higher values signifying better insulation properties. PU panels generally offer superior R-values compared to many other insulation materials, but it's essential to choose panels with an R-value appropriate for your specific climate and building requirements.

Consider the intended use of the space and local building codes when determining the required R-value. For areas with extreme temperatures or stringent energy efficiency standards, you may need panels with higher R-values to ensure optimal thermal performance and compliance with regulations.

Fire Safety and Flame Retardant Properties

Safety is paramount in any construction project, and fire resistance is a crucial aspect to consider when selecting PU insulated sandwich panels. Look for panels that have been tested and certified for fire resistance according to relevant standards. Many high-quality PU panels incorporate flame retardant additives in the polyurethane foam, enhancing their fire safety properties.

When assessing fire safety, pay attention to factors such as flame spread rating, smoke development index, and fire resistance duration. Panels with superior fire-resistant properties can significantly enhance the overall safety of a building, providing valuable time for evacuation in the event of a fire.

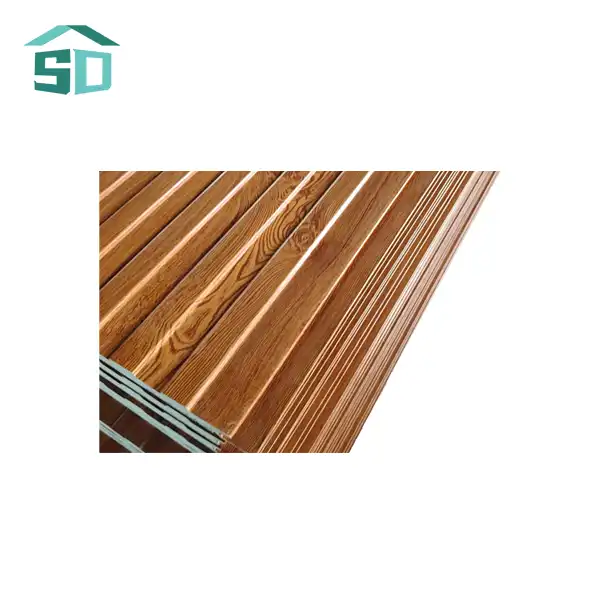

Customization Options and Aesthetic Versatility

While the functional properties of PU insulated sandwich panels are crucial, their aesthetic appeal should not be overlooked. Modern manufacturing techniques allow for a wide range of customization options, enabling these panels to complement various architectural styles and design visions.

Consider the available color options, surface textures, and profile designs when selecting panels. Some manufacturers offer panels with embossed patterns or finishes that mimic other materials, such as wood or stone. This versatility allows architects and designers to achieve their desired aesthetic while still benefiting from the superior performance of PU insulated panels.

Installation Considerations and Long-Term Performance

Ease of Installation and Compatibility with Building Systems

The efficiency of the installation process can significantly impact project timelines and costs. PU insulated sandwich panels are renowned for their ease of installation, often featuring interlocking systems or specialized fastening methods that streamline the construction process. When selecting panels, consider how well they integrate with other building systems, such as framing, electrical, and plumbing.

Evaluate the panel's weight and handling requirements to ensure they are compatible with your project's logistics and labor resources. Lighter panels may offer advantages in terms of ease of handling and reduced structural load, potentially leading to savings in foundation and framing costs.

Maintenance Requirements and Long-Term Cost-Effectiveness

While the initial cost of PU insulated sandwich panels may be higher than some alternative materials, it's essential to consider the long-term cost-effectiveness of this investment. These panels typically require minimal maintenance, reducing ongoing expenses associated with upkeep and repairs.

The durability and weather resistance of high-quality PU panels contribute to their longevity, often outlasting many conventional building materials. When assessing cost-effectiveness, factor in potential energy savings from improved insulation, reduced maintenance costs, and the extended lifespan of the building envelope.

Environmental Impact and Sustainability Considerations

As sustainability becomes an increasingly important factor in construction projects, it's crucial to consider the environmental impact of PU insulated sandwich panels. While polyurethane is a synthetic material, many manufacturers are making strides in improving the sustainability of their products.

Look for panels that incorporate recycled materials or use eco-friendly blowing agents in the polyurethane foam. Some manufacturers offer take-back programs or have implemented closed-loop recycling processes for end-of-life panels. Additionally, consider the energy-saving potential of high-performance PU panels, which can contribute to reduced carbon emissions over the building's lifetime.

Conclusion

Choosing the best PU insulated sandwich panels requires a comprehensive evaluation of various factors, including insulation performance, durability, fire safety, and aesthetic versatility. By carefully considering these aspects and aligning them with your specific project requirements, you can select panels that offer optimal performance, longevity, and value.

Remember that the initial investment in high-quality PU insulated sandwich panels often pays dividends in terms of energy efficiency, reduced maintenance costs, and enhanced building performance over time. As you navigate the selection process, don't hesitate to consult with experts or request detailed product information from reputable manufacturers.

For more information on PU insulated sandwich panels and expert guidance on selecting the best options for your project, feel free to reach out to us at info@sdqsc.com. Our team of specialists is ready to assist you in making an informed decision that aligns with your construction goals and performance requirements.

References

1. Thermal Insulation Association of Canada. "R-Value and Insulation."

2. National Fire Protection Association. "Fire Testing."

3. U.S. Department of Energy. "Insulation Materials."

4. Building Science Corporation. "Guide to Insulating Sheathing."