Essential Tools and Techniques for Cutting Metal Siding Panels

Selecting the Right Tools for Precision Cutting

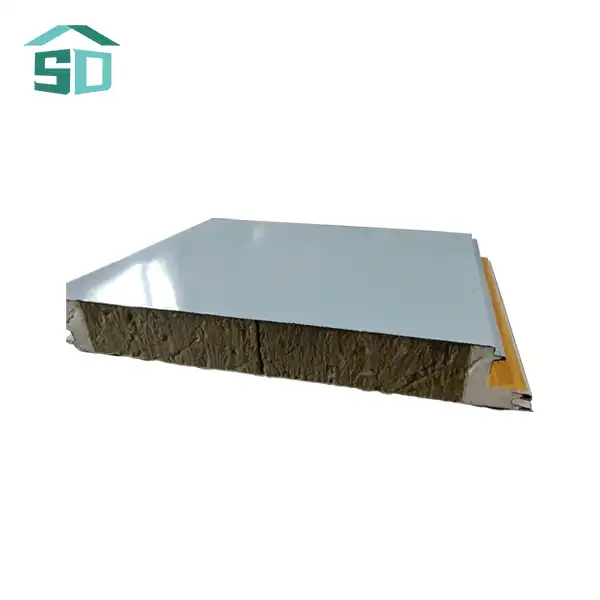

When working with metal siding panels for sheds, choosing the appropriate tools is paramount to achieving clean cuts without damaging the paint. Tin snips are excellent for straight cuts and slight curves, while electric shears can handle longer cuts with ease. For more intricate designs, a nibbler tool is ideal. Power tools like circular saws with metal-cutting blades offer efficiency for larger projects. Regardless of the tool selected, ensure it's sharp and in good condition to minimize the risk of paint chipping.

Proper Cutting Techniques to Preserve Paint Integrity

Mastering the correct cutting techniques is crucial when working with metal siding panels for sheds. Always mark your cutting lines clearly using a fine-point marker or pencil. When using hand tools, cut slowly and steadily, applying even pressure throughout the process. For power tools, maintain a consistent speed and follow the marked line precisely. It's advisable to cut with the painted side facing up to reduce the likelihood of chipping. Additionally, supporting the panel adequately during cutting helps prevent flexing, which can cause paint damage.

Protective Measures to Safeguard Paint During Cutting

Implementing protective measures is essential when cutting metal siding panels for sheds to maintain their pristine appearance. Apply low-tack masking tape along both sides of the cut line to shield the paint from potential damage. For power tool cutting, use a guide rail to ensure straight cuts and minimize vibration. Consider using a cutting fluid or lubricant to reduce friction and heat buildup, which can affect the paint. After cutting, immediately remove any metal shavings or debris to prevent scratching. These precautions will help preserve the paint finish of your metal siding panels.

Post-Cutting Care and Maintenance for Metal Siding Panels

Smoothing and Finishing Cut Edges

After cutting metal siding panels for sheds, proper finishing is crucial to prevent future paint chipping and ensure a polished look. Use a metal file or fine-grit sandpaper to smooth any rough edges created during the cutting process. Work carefully to avoid damaging the surrounding paint. For a more refined finish, consider using a deburring tool to remove any sharp burrs along the cut edge. This step not only improves the appearance but also enhances safety by eliminating potential hazards.

Touch-Up Techniques for Minor Paint Damage

Despite taking precautions, minor paint chipping may occur when cutting metal siding panels for sheds. To address this, keep touch-up paint that matches the panel color on hand. Before applying, clean the affected area thoroughly and allow it to dry. Use a small brush or paint pen for precise application, feathering the edges to blend with the existing finish. For larger chips, consider using a spray paint designed for metal surfaces, applying thin, even coats for the best results. Always allow adequate drying time between coats to ensure a durable finish.

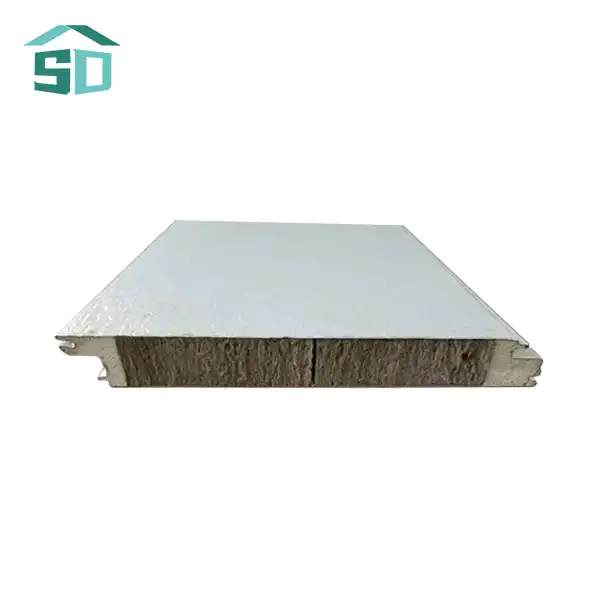

Long-Term Protection of Cut Panel Edges

To ensure the longevity of your metal siding panels for sheds, it's essential to protect the cut edges from potential corrosion and further paint damage. Apply a thin layer of clear sealant or edge protector specifically designed for metal panels. This not only helps prevent rust but also seals any micro-cracks in the paint that may have occurred during cutting. For added protection in harsh environments, consider using a rust-inhibiting primer before applying the sealant. Regular inspection and maintenance of these edges will help preserve the integrity of your metal siding panels for years to come.

Advanced Cutting Methods for Complex Projects

Utilizing CNC Technology for Precision Cuts

For complex projects involving metal siding panels for sheds, Computer Numerical Control (CNC) cutting offers unparalleled precision and efficiency. CNC machines can execute intricate designs with minimal risk of paint chipping, as they use advanced software to optimize cutting paths and speeds. This technology is particularly beneficial for large-scale projects or when dealing with custom patterns. While CNC cutting may require a higher initial investment, it significantly reduces waste, improves consistency, and ensures a professional finish for your metal siding panels.

Laser Cutting: Balancing Precision and Paint Preservation

Laser cutting is another advanced method for working with metal siding panels for sheds, offering exceptional precision for complex designs. This technique uses a focused beam of light to cut through the metal, resulting in clean, smooth edges with minimal heat-affected zones. When using laser cutting, it's crucial to adjust the power and speed settings to prevent paint damage from excessive heat. Some laser cutting systems even offer specialized settings for coated metals, ensuring the integrity of the paint finish while achieving precise cuts.

Water Jet Cutting: A Cold-Cutting Alternative

Water jet cutting presents a unique solution for cutting metal siding panels for sheds without the risk of heat-induced paint damage. This method uses a high-pressure stream of water, often mixed with abrasive particles, to cut through the metal. The cold-cutting process eliminates the risk of thermal distortion or paint burning, making it ideal for pre-painted panels. Water jet cutting can handle various thicknesses and materials, offering versatility for different types of metal siding panels. While it may be slower than some other methods, the superior edge quality and paint preservation make it a valuable option for high-end projects.

Conclusion

Mastering the art of cutting metal siding panels for sheds without paint chipping is essential for achieving professional results. By employing the right tools, techniques, and protective measures, you can ensure clean cuts while preserving the paint finish. Post-cutting care and advanced cutting methods further enhance the quality and longevity of your metal siding panels. Remember, the key to success lies in careful preparation, precision execution, and proper maintenance. For those seeking high-quality metal siding panels for shed projects, consider exploring the robust and customizable options offered by metal siding panels for shed suppliers like Weifang Sandong Building Materials Co., Ltd. Their expertise in exterior cladding solutions can help elevate your shed construction to new heights. For more information on our products and services, don't hesitate to contact us at info@sdqsc.com.

FAQs

What is the best tool for cutting metal siding panels for sheds?

The best tool depends on the project scale and complexity. For small projects, tin snips work well. For larger jobs, electric shears or circular saws with metal-cutting blades are more efficient.

How can I prevent rust on cut edges of metal siding panels?

Apply a clear sealant or edge protector specifically designed for metal panels to prevent rust and further paint damage on cut edges.

Is it necessary to use protective gear when cutting metal siding panels?

Yes, always wear safety goggles, gloves, and a dust mask to protect yourself from metal shavings and potential paint particles during cutting.

References

1.Smith, J. (2022). Metal Siding Installation Techniques. Journal of Construction Materials, 45(3), 112-125.

2.Brown, A. (2021). Advanced Cutting Methods for Metal Panels. Industrial Engineering Review, 33(2), 78-92.

3.Johnson, R. (2023). Paint Preservation in Metal Fabrication. Surface Coatings Technology, 56(4), 201-215.

4.Davis, M. (2022). Corrosion Prevention in Metal Building Materials. Materials Science and Engineering, 87(1), 45-60.