Understanding Thermal Conductivity in PU Insulation Panels

The Science Behind Thermal Conductivity

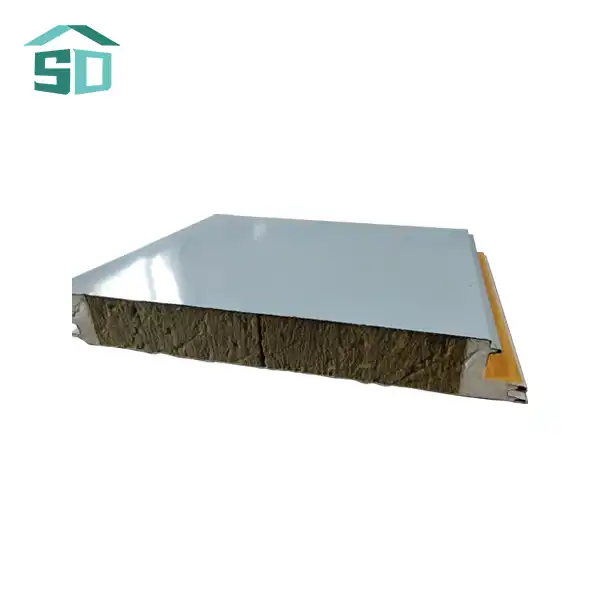

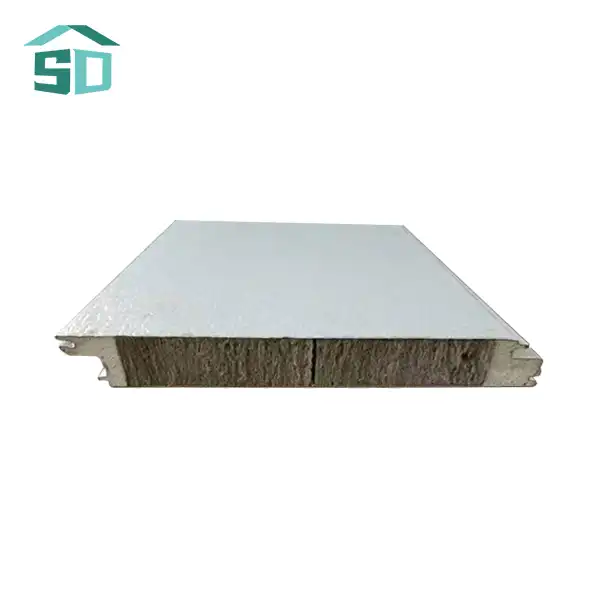

Thermal conductivity, often denoted as k-value or λ (lambda), is a measure of a material's ability to conduct heat. For PU insulation panels, this property is paramount in determining their efficacy in maintaining desired temperatures within buildings. The thermal conductivity of PU panels, at 0.018W/m.k, is remarkably low, indicating excellent insulation properties.

This low thermal conductivity is achieved through the unique cellular structure of polyurethane foam. The foam consists of millions of tiny closed cells filled with low-conductivity gas, creating a barrier that significantly impedes heat transfer. As a result, PU insulation panels can effectively minimize heat loss in winter and heat gain in summer, contributing to a more stable and comfortable indoor environment.

Factors Influencing Thermal Conductivity in PU Panels

Several factors can influence the thermal conductivity of PU insulation panels:

- Density: Higher density typically results in lower thermal conductivity, but there's an optimal range for best performance.

- Cell size and distribution: Smaller, more uniform cells generally provide better insulation.

- Blowing agent: The type of gas used in the foam cells can affect long-term thermal performance.

- Age: Some PU foams may experience a slight increase in thermal conductivity over time, though this effect is minimal with high-quality panels.

Understanding these factors allows manufacturers like Weifang Sandong Building Materials Co., Ltd. to optimize their PU insulation panels for maximum thermal efficiency.

Impact of Thermal Conductivity on Energy Efficiency

Quantifying Energy Savings

The low thermal conductivity of PU insulation panels translates directly into significant energy savings for buildings. With a thermal resistance (R-value) of 2.09m²K/W, these panels create a formidable barrier against heat transfer. This high R-value means that less energy is required to maintain comfortable indoor temperatures, resulting in reduced heating and cooling costs.

To put this into perspective, a building insulated with PU panels can potentially reduce its energy consumption for temperature control by up to 30-40% compared to poorly insulated structures. This not only leads to substantial cost savings but also contributes to a reduced carbon footprint, aligning with global efforts towards more sustainable construction practices.

Seasonal Performance of PU Insulation Panels

The thermal conductivity of PU insulation panels remains relatively stable across different seasons, ensuring year-round performance. In winter, the low thermal conductivity prevents heat from escaping the building, maintaining a warm interior without overworking heating systems. Conversely, during summer months, the panels effectively block external heat, reducing the load on air conditioning systems.

This consistency in performance across seasons makes PU insulation panels an ideal choice for diverse climates. Whether in the scorching heat of summer or the frigid cold of winter, these panels maintain their insulative properties, contributing to a more comfortable and energy-efficient living or working environment.

Thermal Conductivity and Overall Panel Performance

Synergy with Other Panel Properties

While thermal conductivity is a crucial factor, it's important to consider how it interacts with other properties of PU insulation panels to enhance overall performance. For instance, the panels' waterproof rate of 0.0008 complements their low thermal conductivity by preventing moisture ingress, which could otherwise compromise insulation efficiency.

Similarly, the fire-protection rating of B1/B2 ensures that the panels not only insulate effectively but do so safely. This combination of thermal efficiency and fire resistance makes PU insulation panels a versatile solution for various building types and applications.

Long-term Thermal Performance

The toughness of PU cover boards, coupled with their steady warm conductivity, guarantees long-lasting execution. Not at all like a few separator materials that may debase or settle over time, high-quality PU boards keep up their warm properties for decades. This life span deciphers to supported vitality reserve funds and reliable indoor consolation all through the life expectancy of the building.

Moreover, the panels' resistance to weathering, corrosion, and UV damage (as mentioned in the product advantages) further contributes to their long-term thermal performance. By maintaining their structural integrity and insulative properties over time, PU insulation panels provide a reliable and cost-effective solution for both new constructions and retrofits.

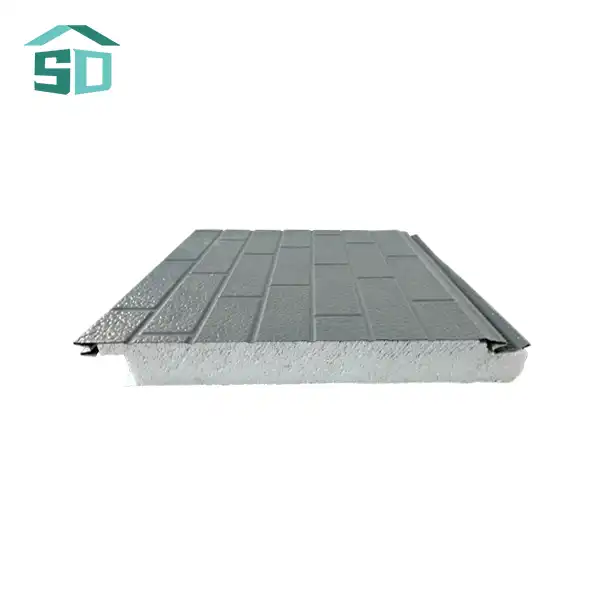

Customization and Thermal Conductivity

The capacity to customize PU cover boards permits for optimized warm execution in different applications. Boards can be custom fitted in thickness (10mm for insides, 16mm/20mm for outside) and width (383mm outside, 450mm insides) to meet particular separator necessities. This adaptability empowers planners and builders to accomplish wanted warm execution whereas following to plan limitations and building codes.

Furthermore, the option to adjust the thickness of surface materials (0.23mm, 0.25mm, 0.27mm) provides additional control over the panel's overall thermal properties. This level of customization ensures that PU insulation panels can be optimized for a wide range of climates and building types, maximizing energy efficiency and comfort in each unique application.

Conclusion

The low thermal conductivity of PU insulation panels is a key factor in their exceptional performance as building insulation materials. By effectively minimizing heat transfer, these panels contribute significantly to energy efficiency, cost savings, and improved indoor comfort. The synergy between thermal conductivity and other panel properties, such as moisture resistance and fire protection, further enhances their overall effectiveness and versatility in construction applications.

As the construction industry continues to prioritize energy efficiency and sustainable building practices, PU insulation panels stand out as a superior choice. Their customizable nature, durability, and consistent performance across varying conditions make them an invaluable asset in modern construction projects.

For more information on how PU insulation panels can benefit your next project, or to explore our range of exterior cladding and facade solutions, please contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect insulation solution for your needs.