The Science Behind Metal Sheet PU Sandwich's Energy Efficiency

Thermal Conductivity: A Game-Changer in Insulation

The energy effectiveness of essence distance PU sandwich panels is primarily attributed to their exceptional thermal conductivity parcels. With a thermal conductivity value of 0.018 W/m.k, these panels outperform numerous traditional sequestration accoutrements. This low thermal conductivity means that heat transfer through the panel is minimum, effectively creating a thermal hedge between the innards and surface surroundings.

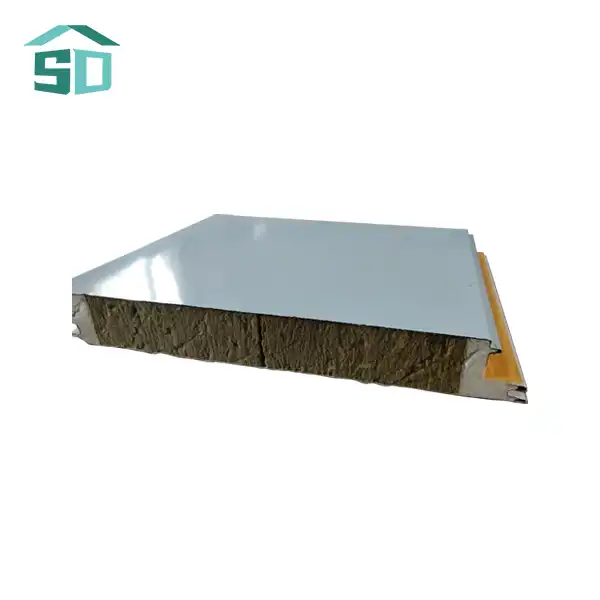

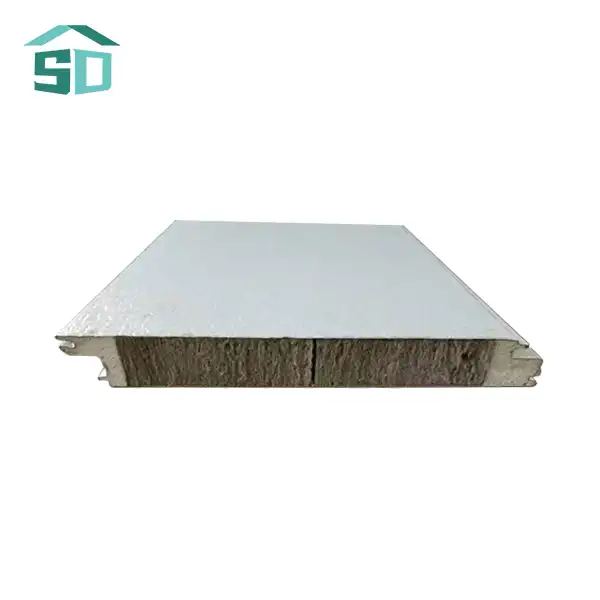

The polyurethane foam core is the key player in this thermal performance. PU foam consists of millions of tiny, closed cells filled with low-conductivity gas. This cellular structure dramatically reduces heat flow, making it an ideal insulator. When sandwiched between metal sheets, the PU foam's insulating properties are further enhanced, creating a robust thermal envelope for the building.

Thermal Resistance: Maximizing Insulation Effectiveness

Complementing the low thermal conductivity is the high thermal resistance of metal sheet PU sandwich panels. With a thermal resistance value of 2.09 m²/kW, these panels provide a formidable barrier against heat flow. This high R-value ensures that the internal temperature of a building remains stable, reducing the workload on HVAC systems and consequently lowering energy consumption.

The thermal resistance of these panels is particularly beneficial in extreme climates. In hot regions, they prevent the scorching exterior heat from penetrating the building's interior, while in cold areas, they retain the warmth inside, minimizing heat loss. This versatility makes metal sheet PU sandwich panels an ideal choice for energy-efficient construction across various geographical locations.

Structural Advantages Contributing to Energy Efficiency

Customizable Thickness for Optimal Insulation

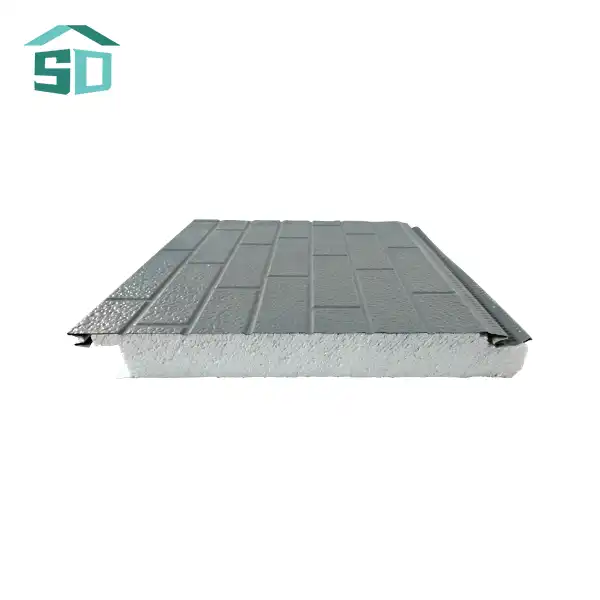

One of the key advantages of metal sheet PU sandwich panels is their customizable thickness. For interior applications, panels can be as thin as 10mm, while exterior panels are available in 16mm or 20mm thicknesses. This flexibility allows architects and builders to tailor the insulation level to specific project requirements, optimizing energy efficiency without compromising on space or aesthetics.

The ability to adjust panel thickness is particularly valuable in retrofit projects, where space constraints may limit insulation options. Even with thinner panels, the superior insulating properties of PU foam ensure significant energy efficiency improvements compared to traditional building materials.

Airtight Construction for Reduced Energy Loss

Metal sheet PU sandwich panels contribute to energy efficiency not just through their insulating properties, but also through their airtight construction. The panels are designed to fit together seamlessly, minimizing air leakage and thermal bridging. This airtight seal is crucial for maintaining a consistent internal temperature and preventing unwanted heat exchange with the external environment.

The panels' waterproof rate of 0.0008 further enhances their ability to create an impermeable barrier. This not only protects against moisture ingress but also prevents air infiltration, a common source of energy loss in buildings. By eliminating these weak points in the building envelope, metal sheet PU sandwich panels significantly boost overall energy efficiency.

Long-Term Energy Efficiency and Sustainability

Durability and Performance Longevity

The energy efficiency of metal sheet PU sandwich panels is not just a short-term benefit; it's a long-lasting advantage. The durability of these panels ensures that their insulating properties remain effective over time. The metal sheets protect the PU foam core from environmental degradation, maintaining its insulation performance for years.

With a compressive strength of 52.7kpa and wind resistance of 8.0 Kpa, these panels can withstand harsh environmental conditions without compromising their structural integrity or insulating capabilities. This resilience translates to consistent energy efficiency throughout the building's lifecycle, reducing the need for frequent replacements or repairs that could impact overall energy performance.

Eco-Friendly Aspects of Metal Sheet PU Sandwich Panels

Beyond their direct impact on energy efficiency, metal sheet PU sandwich panels also contribute to sustainability in several ways. The panels' lightweight nature reduces transportation costs and energy consumption during installation. Their long lifespan minimizes the need for replacement, reducing waste and resource consumption over time.

Moreover, many manufacturers are now focusing on using recyclable materials and environmentally friendly production processes for these panels. Some are even incorporating recycled content into the metal sheets, further enhancing the panels' eco-friendly profile. By choosing metal sheet PU sandwich panels, builders and property owners are not only improving energy efficiency but also supporting broader sustainability goals in the construction industry.

Conclusion

Metal sheet PU sandwich panels represent a significant leap forward in building energy efficiency. Their exceptional thermal properties, customizable design, and long-term durability make them an ideal choice for energy-conscious construction projects. As the world continues to grapple with energy conservation and sustainability challenges, these innovative panels offer a practical and effective solution.

For those looking to enhance the energy efficiency of their buildings while also benefiting from the durability, fire resistance, and aesthetic versatility of metal sheet PU sandwich panels, Weifang Sandong Building Materials Co., Ltd. offers a range of high-quality options. To learn more about how these panels can transform your construction project, contact us at info@sdqsc.com.

References

1.Alagar, S., Abubakar, A. A., & Umar, K. S. (2020). Performance evaluation of PU foam-based sandwich panels for energy efficiency in building envelopes. Energy Conversion and Management, 227, 113565.

2.Thormark, C. (2006). The effect of material choice on the total energy need and recycling potential of a building. Building and Environment, 41(8), 1019–1026.

3.Grynning, S., Time, B., & Jelle, B. P. (2015). Experimental investigation of thermal bridges in sandwich panel building systems. Energy and Buildings, 92, 303–311.

4.Johansson, P. O., & Hallbom, E. (2018). Long-term moisture and thermal performance of sandwich panel assemblies. Journal of Building Physics, 42(4), 295–312.

5.Bann, D., & Logan, B. (2016). Fire behavior and safety of sandwich facades: A comprehensive review. Fire Technology, 52(3), 517–543.

6.Cabeza, L. F., et al. (2019). Sustainability and life cycle assessment (LCA) of PU insulated metal panels used in energy-efficient buildings. Journal of Cleaner Production, 231, 1345–1356.