The Composition and Construction of Thermal Wall Panels

Thermal wall panels are meticulously designed to provide superior insulation and durability. These panels typically consist of three main components: an outer facing, an insulation core, and an inner facing. The outer facing is usually made of steel, aluminum, or stainless steel, chosen for their strength and weather resistance. This layer acts as the first line of defense against harsh environmental conditions.

The insulation core, often composed of polyurethane or rock wool, is the heart of the thermal panel. It plays a decisive role in thermal efficiency by providing outstanding resistance to heat transfer, which helps maintain stable indoor temperatures throughout seasonal changes. This not only reduces heating and cooling energy consumption but also lowers long-term utility costs. With thickness options of 50mm, 75mm, and 100mm, it offers flexible customization for diverse project requirements.

The inner facing, similar to the outer layer, provides additional structural support and a finished appearance for the interior. Beyond enhancing strength, it also improves fire resistance and helps protect the insulation core from potential damage. Its smooth and refined surface ensures a clean, polished look, making spaces visually appealing. Together with the core and outer layer, this three-layer construction forms a robust thermal barrier against heat, moisture, and external weather conditions.

Advanced Manufacturing Techniques

The durability of thermal wall panels is further enhanced by advanced manufacturing techniques. These panels undergo rigorous quality control processes, ensuring that each component meets stringent standards. The bonding between the layers is crucial, as it prevents delamination and maintains the panel's integrity over time. Modern production lines utilize state-of-the-art technology to create a seamless bond, resulting in panels that can withstand thermal expansion and contraction without compromising their structure.

Performance of Thermal Panels in Extreme Weather Conditions

Thermal wall panels are designed to excel in a wide range of weather conditions, making them suitable for use in various climates. In regions with extreme heat, these panels act as an effective barrier against solar radiation, preventing excessive heat gain and reducing cooling costs. The outer layer, often treated with UV-resistant coatings, resists fading and degradation from prolonged sun exposure.

In cold climates, thermal panels provide excellent insulation, maintaining warm indoor temperatures and preventing heat loss. Their ability to minimize thermal bridging—areas where heat can escape more easily—contributes to their effectiveness in cold environments. This property not only enhances comfort but also significantly reduces heating expenses.

Resistance to Moisture and Corrosion

One of the key factors in the durability of thermal panels is their resistance to moisture and corrosion. The panels are designed with water-resistant properties, preventing water infiltration that could compromise the insulation or lead to structural damage. In coastal areas or regions with high humidity, this moisture resistance is particularly valuable, as it protects against salt corrosion and mold growth.

The corrosion resistance of thermal panels is further enhanced by protective coatings applied to the metal facings. These coatings, which can include galvanization or specialized paint systems, provide an additional layer of defense against rust and other forms of corrosion, ensuring the panels maintain their appearance and functionality over time.

Long-Term Performance and Maintenance of Thermal Wall Panels

The longevity of thermal wall panels is a testament to their durability. When properly installed and maintained, these panels can last for decades, often outlasting other building materials. This extended lifespan is due to their resilient construction and resistance to common forms of deterioration.

Maintenance requirements for thermal panels are typically minimal, contributing to their cost-effectiveness over time. Regular inspections to check for any signs of damage or wear are usually sufficient. The smooth surface of many thermal panels also makes them easy to clean, resisting the buildup of dirt and debris that can affect other types of cladding.

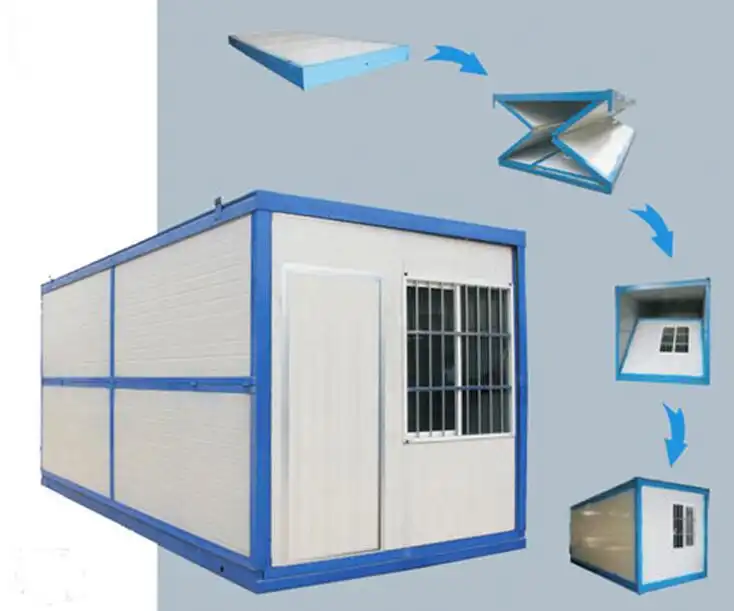

Adaptability to Different Building Types

The versatility of thermal wall panels allows them to be used in a wide range of building types, from residential homes to industrial facilities. Their adaptability to different architectural styles and their ability to meet various building codes and standards make them a popular choice for both new construction and renovation projects. The panels can be customized in terms of size, color, and finish, allowing architects and builders to achieve their desired aesthetic while benefiting from the panels' durability and performance.

Conclusion

Thermal wall panels have demonstrated remarkable durability in harsh conditions, making them an excellent choice for modern construction projects. Their robust construction, featuring high-quality materials and advanced manufacturing techniques, enables them to withstand extreme temperatures, moisture, UV radiation, and physical impacts. The combination of durability, energy efficiency, and aesthetic versatility positions thermal panels as a superior solution for building envelopes in diverse climates and architectural styles. As the construction industry continues to prioritize sustainability and long-term performance, the role of thermal wall panels in creating resilient, energy-efficient buildings is likely to grow.

Are you looking to enhance your building's durability and energy efficiency? Consider incorporating our thermal wall panels into your next project. At Weifang Sandong Building Materials Co., Ltd., we offer a wide range of high-quality thermal panels designed to meet your specific needs. For more information or to discuss your project requirements, please contact us at info@sdqsc.com.

FAQ

How long do thermal wall panels typically last?

With proper installation and maintenance, thermal wall panels can last 30-50 years or more, depending on the environmental conditions and specific product quality.

Can thermal panels withstand extreme temperature fluctuations?

Yes, thermal panels are designed to handle significant temperature variations without compromising their structural integrity or insulating properties.

Are thermal wall panels fire-resistant?

Many thermal panels come with fire-resistant ratings (Class A or B), offering enhanced safety in case of fire. However, specific fire resistance can vary by product.

References

1.Thermal Insulation Manufacturers Association. (2023). "Thermal Insulation Materials: Properties and Applications."

2.Journal of Building Engineering. (2022). "Long-term Performance of Insulated Metal Panels in Extreme Climates."

3.American Society for Testing and Materials. (2023). "Standard Test Methods for Fire Tests of Building Construction and Materials."

4.International Energy Agency. (2023). "Energy Efficiency in Buildings: The Role of Insulation."