The Science Behind Colored Corrugated Metal Siding's Insulation Properties

Understanding the sequestration parcels of colored corrugated essence siding requires probing into the drugs of heat transfer and the unique characteristics of this material. The corrugated design is n't just for aesthetics; it plays a pivotal part in enhancing the siding's insulative rates.

Thermal Bridging Reduction

One of the primary ways colored corrugated metal siding improves insulation is by reducing thermal bridging, which occurs when heat bypasses insulation through more conductive materials. The corrugated pattern naturally creates air pockets between the outer metal layer and the inner building envelope. These air gaps act as thermal buffers, reducing the direct transfer of heat or cold. As a result, the overall R-value of the wall assembly is enhanced, contributing to improved indoor comfort and energy savings.

Reflective Properties

The color and finish of corrugated metal siding play a critical role in its thermal efficiency. Light-colored and reflective coatings can significantly improve solar reflectance, bouncing back a substantial amount of solar radiation. This property helps prevent heat absorption during hot weather, effectively lowering indoor temperatures and reducing the burden on HVAC systems. By mitigating thermal gain, these reflective surfaces support more energy-efficient buildings and contribute to maintaining consistent indoor climate conditions.

Material Composition

The insulative performance of colored corrugated metal siding is also influenced by the base material. Metals such as aluminum, steel, stainless steel, and copper each possess distinct thermal properties. For example, aluminum’s low thermal mass allows it to cool quickly after sunset, making it ideal in regions with high daytime temperatures. Meanwhile, coated steel offers excellent durability and moderate insulation. Choosing the right material enables architects to optimize energy efficiency based on the building’s location and climate.

Enhanced Insulation Through Customization and Additional Features

Colored corrugated essence siding offers a high degree of customization, allowing for optimization of sequestration parcels to suit specific climate conditions and structure conditions.

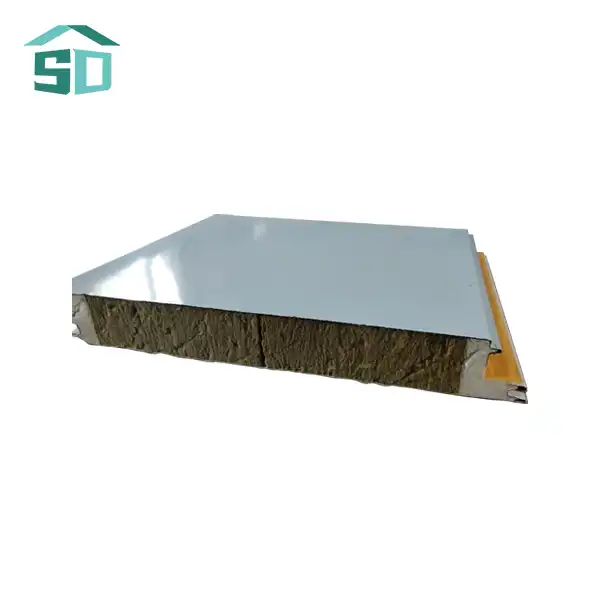

The ability to customize the dimensions and thickness of colored corrugated metal siding panels provides a significant advantage in achieving optimal thermal efficiency. Thicker panels, typically ranging from 0.3 mm to 1.2 mm, offer better resistance to heat flow, enhancing insulation. Custom sizing ensures that the panels fit snugly against the building’s surface, reducing air leaks or thermal bridges that could compromise energy performance, particularly in extreme climates or high-efficiency projects.

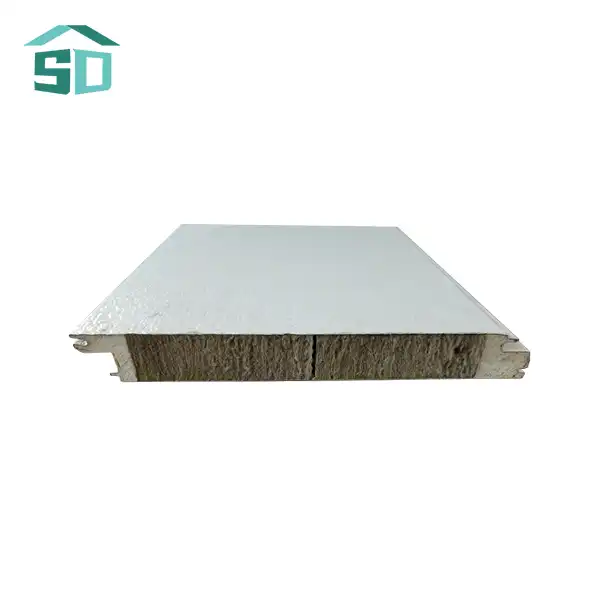

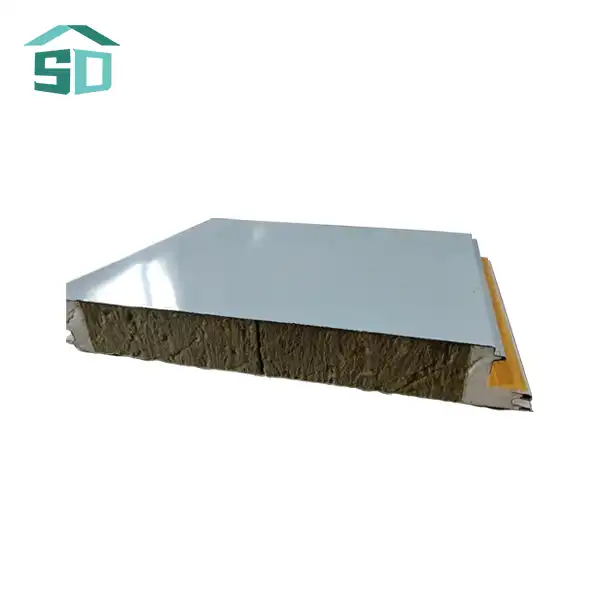

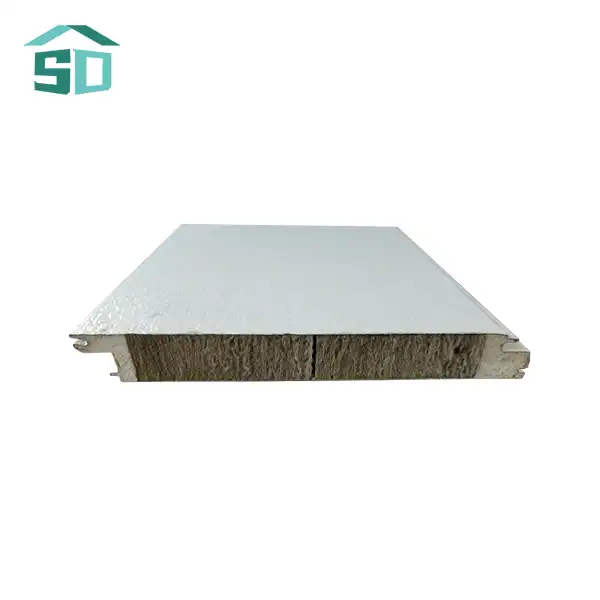

Integration with Insulation Materials

Colored corrugated metal siding can be paired with a wide range of insulation materials to create a comprehensive thermal barrier. Common choices such as polyurethane, polystyrene, rock wool, and glass wool offer varying degrees of thermal resistance and fire protection. These materials can be layered behind the siding or incorporated into composite panel systems, dramatically improving heat retention in cold weather and reflecting heat in warm conditions, thus boosting the building's overall energy efficiency.

Surface Treatments for Improved Performance

Surface treatments like painting, powder coating, and anodizing enhance both the performance and longevity of colored corrugated metal siding. These treatments can increase the panels’ reflectivity, improving solar heat management, especially in hot climates. Additionally, they protect the metal from corrosion, UV damage, and weather-induced wear, which helps preserve thermal performance over time. Treated surfaces also maintain their aesthetic appeal and structural integrity longer, making them ideal for sustainable construction.

Long-Term Benefits and Sustainability of Colored Corrugated Metal Siding

The advantages of colored corrugated essence siding extend beyond immediate sequestration advancements, offering long- term benefits and contributing to sustainable structure practices.

Durability and Low Maintenance

Colored corrugated metal siding is widely appreciated for its exceptional durability and minimal maintenance needs. It is engineered to resist corrosion, UV damage, moisture, and even fire, allowing it to maintain its structural and thermal integrity over extended periods. This resilience reduces the frequency of repairs or replacements, lowering lifecycle costs and waste. As a result, it serves as a long-term, sustainable solution for building exteriors across diverse climates and applications.

Energy Savings and Reduced Carbon Footprint

Enhanced insulation provided by colored corrugated metal siding leads to noticeable energy savings over time. By reducing the need for excessive heating in winter and cooling in summer, these panels help lower energy consumption and associated costs. The resulting decrease in fossil fuel usage contributes to a smaller carbon footprint. This benefit aligns with environmentally friendly design goals and supports certification efforts like LEED or other sustainable building rating systems.

Recyclability and Eco-Friendly Options

Many types of colored corrugated metal siding are recyclable, contributing to the circular economy. Additionally, eco-conscious builders can choose sustainable material options that further reduce environmental impact. This combination of energy efficiency and material sustainability makes colored corrugated metal siding an excellent choice for environmentally responsible construction.

Conclusion

Colored corrugated metal siding stands out as a versatile and efficient solution for improving building insulation. Its unique design, customizable features, and long-term benefits make it an attractive option for both residential and commercial applications. By combining aesthetic appeal with superior thermal performance, this innovative material is helping to shape the future of energy-efficient building design.

For those looking to enhance their building's insulation while maintaining a stylish exterior, colored corrugated metal siding offers an unparalleled combination of form and function. To learn more about how colored corrugated metal siding can improve your building's insulation and overall performance, contact us at info@sdqsc.com.