The Evolution of Building Materials: Enter Insulated Sandwich Panels

The construction industry has come a long way from traditional building materials like brick and wood. As sustainability becomes increasingly crucial, innovative solutions have emerged to meet the demands of modern, eco-friendly construction. Insulated sandwich panels represent a significant leap forward in this evolution.

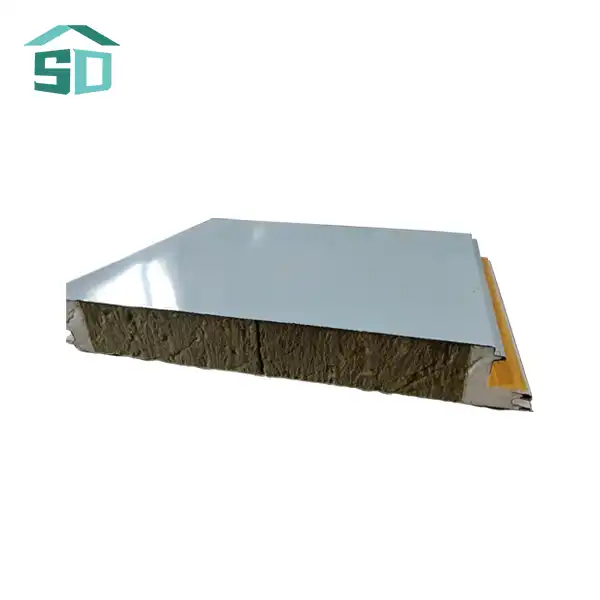

These panels are engineered to provide exceptional thermal insulation, structural strength, and aesthetic appeal. The core of an insulated sandwich panel typically consists of materials like polyurethane, polystyrene, rock wool, or glass wool, sandwiched between two metal sheets. This unique construction offers numerous advantages over conventional building materials.

Composition and Design

The multi-layer construction of insulated sandwich panels is key to their performance. The outer metal sheets, which can be made from aluminum, steel, stainless steel, or copper, provide durability and weather resistance. The insulating core is the heart of the panel, offering superior thermal and acoustic insulation properties.

Thickness options for these panels typically range from 50mm to 150mm, allowing for customization based on specific project requirements. The ability to choose from various materials and thicknesses enables architects and builders to optimize the panels for different climates and building types.

Versatility in Application

Insulated sandwich panels are remarkably versatile, finding applications across various sectors of the construction industry. They are commonly used in:

- Residential complexes

- Office buildings

- Industrial warehouses

- Agricultural structures

- Cold storage facilities

- Educational institutions

- Healthcare facilities

This versatility stems from their adaptability to different architectural styles and functional requirements. Whether it's a modern office building requiring a sleek facade or a warehouse needing robust insulation, these panels can be tailored to meet diverse needs.

Sustainability at the Core: Energy Efficiency and Environmental Impact

The revolution brought about by insulated sandwich panels in sustainable construction is primarily due to their outstanding energy efficiency and reduced environmental impact. These panels are at the forefront of green building practices, contributing significantly to the reduction of a building's carbon footprint.

Superior Thermal Performance

One of the most significant advantages of insulated sandwich panels is their exceptional thermal insulation properties. The insulating core effectively minimizes heat transfer between the interior and exterior of a building. This superior thermal performance translates to reduced energy consumption for heating and cooling, which is a major contributor to a building's overall energy use.

Buildings constructed with these panels can maintain comfortable indoor temperatures with less reliance on HVAC systems. This not only leads to lower energy bills but also reduces the strain on energy resources, contributing to overall sustainability goals.

Reduced Carbon Footprint

The energy efficiency of insulated sandwich panels directly correlates to a reduction in carbon emissions. By decreasing the energy required for temperature control, buildings equipped with these panels emit fewer greenhouse gases over their lifetime. This aligns perfectly with global efforts to combat climate change and reduce the environmental impact of the construction industry.

Moreover, the manufacturing process of these panels is often more energy-efficient compared to traditional building materials. Many manufacturers are adopting sustainable practices in their production lines, further enhancing the eco-friendly profile of insulated sandwich panels.

Longevity and Reduced Waste

Sustainability in construction isn't just about energy efficiency; it also involves the longevity of materials and waste reduction. Insulated sandwich panels excel in both these aspects. Their durable construction, often featuring corrosion-resistant materials, ensures a long lifespan. This durability translates to less frequent replacements and repairs, reducing waste and resource consumption over time.

Additionally, these panels are often recyclable at the end of their life cycle. The metal facings can be recycled, and some insulating materials can be repurposed, contributing to a circular economy in construction.

Revolutionizing Construction Practices: Efficiency and Innovation

Beyond their environmental benefits, insulated sandwich panels are transforming construction practices, offering unprecedented efficiency and innovative solutions to long-standing challenges in the industry.

Streamlined Installation Process

One of the most revolutionary aspects of insulated sandwich panels is their ease and speed of installation. Traditional construction methods often involve multiple steps and materials, leading to longer construction times and increased labor costs. In contrast, these panels offer a simplified, streamlined installation process:

1.Preparation: Ensuring the surface is clean and dry.

2.Alignment: Correctly positioning the panel.

3.Fixing: Securing panels using screws or adhesive.

4.Sealing: Applying sealants to joints for enhanced insulation and moisture resistance.

This efficiency not only reduces construction time but also minimizes on-site waste and disruption, making it an ideal solution for both new constructions and renovations.

Customization and Aesthetic Flexibility

Insulated sandwich panels offer a level of customization that was previously challenging to achieve with traditional materials. They come in a wide range of colors and finishes, allowing architects and designers to create visually striking buildings without compromising on performance.

The ability to customize these panels extends beyond aesthetics. Different core materials can be selected based on specific insulation requirements, fire ratings, or acoustic needs. This flexibility allows for tailored solutions that meet both the functional and visual demands of modern architecture.

Advanced Fire Safety

Fire safety is a critical concern in construction, and insulated sandwich panels are engineered to meet stringent fire safety regulations. Many panels are designed with fire-resistant cores and achieve relevant fire safety standards, providing peace of mind for building owners and occupants alike.

This advanced fire safety feature, combined with their other benefits, makes these panels an attractive option for a wide range of building types, from residential to industrial.

Conclusion

Insulated sandwich panels have undeniably revolutionized sustainable construction. Their superior thermal performance, durability, and versatility make them a cornerstone of modern, eco-friendly building practices. By significantly reducing energy consumption, minimizing waste, and offering long-lasting solutions, these panels address many of the sustainability challenges faced by the construction industry. Their ease of installation, customization options, and advanced safety features further cement their position as a game-changing technology in sustainable construction.

As we move towards a more sustainable future, the role of innovative materials like insulated sandwich panels becomes increasingly crucial. At Weifang Sandong Building Materials Co., Ltd., we're committed to providing high-quality, sustainable building solutions. Our range of insulated sandwich panels combines cutting-edge technology with environmental responsibility, helping you create energy-efficient, durable, and aesthetically pleasing structures. To learn more about how our products can revolutionize your construction projects, contact us at info@sdqsc.com.

FAQ

What makes insulated sandwich panels more sustainable than traditional building materials?

Insulated sandwich panels offer superior thermal insulation, reducing energy consumption for heating and cooling. They're also durable, recyclable, and require less material overall, minimizing waste and environmental impact.

Can insulated sandwich panels be used in all types of buildings?

Yes, these panels are versatile and can be used in residential, commercial, industrial, and institutional buildings. They're adaptable to various architectural styles and functional requirements.

How do insulated sandwich panels contribute to fire safety in buildings?

Many insulated sandwich panels are engineered with fire-resistant cores and meet stringent fire safety standards, enhancing overall building safety.

References

1.U.S. Department of Energy. (2021). "Energy Efficiency in Commercial Buildings."

2.International Journal of Sustainable Building Technology and Urban Development. (2020). "Advances in Sustainable Construction Materials."

3.World Green Building Council. (2022). "Global Status Report for Buildings and Construction."

4.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2021). "ASHRAE Handbook - Fundamentals."

5.Environmental Protection Agency. (2022). "Sustainable Materials Management in Construction."