The Anatomy of Aluminum Sandwich Panels: Strength Meets Efficiency

At the heart of the aluminum sandwich panel revolution lies its ingenious structure. These panels consist of three main components:

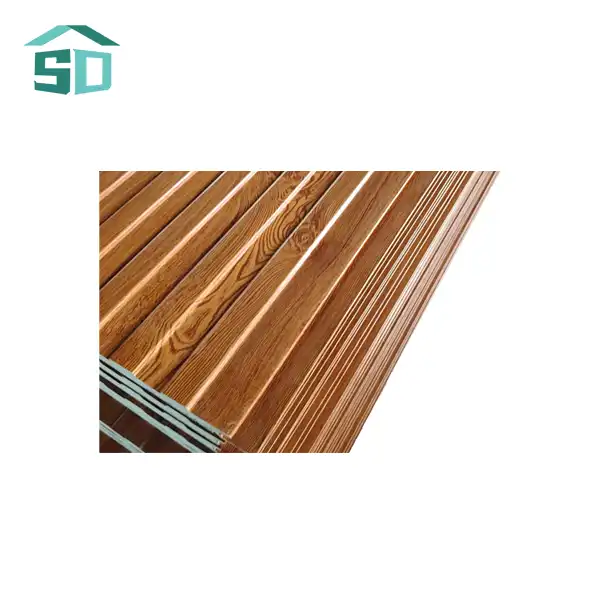

Aluminum Faces: The Durable Exterior

The outer layers of aluminum sandwich panels are crafted from high-quality aluminum sheets that offer superior mechanical strength and environmental resilience. These aluminum faces are engineered to withstand harsh conditions, providing exceptional resistance to corrosion, ultraviolet (UV) radiation, and long-term weathering effects such as rain, snow, and wind. Additionally, the surfaces can be customized through anodizing, powder coating, or PVDF painting, enabling diverse aesthetic choices that align with modern, traditional, or industrial architectural designs.

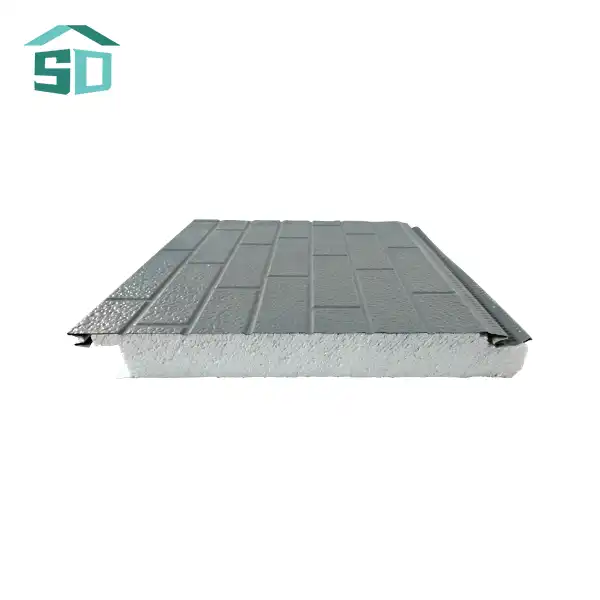

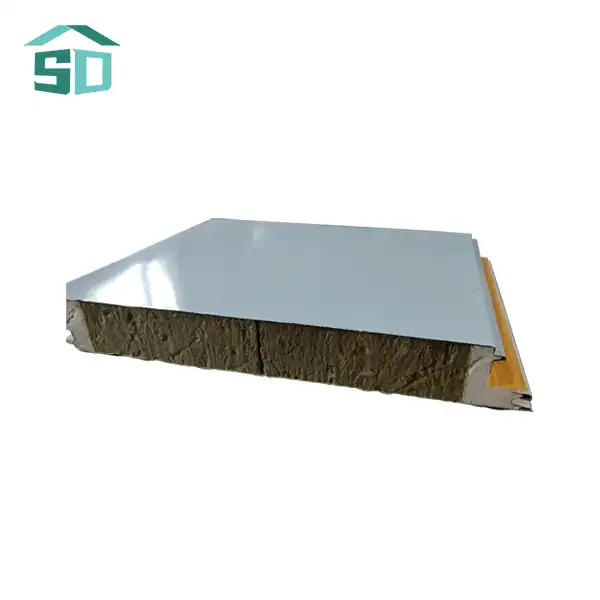

Insulation Core: The Heart of Efficiency

Sandwiched between the aluminum faces is a core of insulating material. This core is typically made of polyurethane, polystyrene, or rock wool, each offering unique benefits. The insulation core is the key to the panel's outstanding thermal performance, significantly reducing heat transfer and enhancing energy efficiency in buildings. This core also contributes to the panel's sound insulation properties, making it an excellent choice for urban environments where noise reduction is crucial.

Bonding Technology: Uniting Strength and Lightness

The aluminum faces and insulation core are bonded together using advanced adhesive technologies. This bonding process creates a strong, unified panel that distributes loads effectively across its surface. The result is a lightweight yet incredibly strong building material that can withstand various environmental stresses while maintaining its structural integrity.

Transforming Construction: The Multifaceted Benefits of Aluminum Sandwich Panels

The adoption of aluminum sandwich panels in construction projects brings a host of advantages that are reshaping the industry:

Unparalleled Lightweight Strength

Despite their robust construction, aluminum sandwich panels are remarkably lightweight, typically weighing between 8-14 kg/m². This low weight significantly reduces the structural load on buildings, allowing for more flexible and innovative designs. The lightweight nature of these panels also simplifies transportation and installation processes, leading to reduced labor costs and faster project completion times.

Superior Thermal Efficiency

The insulation core of aluminum sandwich panels provides exceptional thermal performance. This high level of insulation contributes to significant energy savings in heating and cooling, making buildings more environmentally friendly and cost-effective to operate. The thermal efficiency of these panels is customizable, with thicknesses ranging from 20mm to 150mm to meet specific project requirements.

Versatility in Design and Application

Aluminum sandwich panels offer unparalleled versatility in design and application. They can be easily customized in terms of size, color, and finish, allowing architects and designers to realize their creative visions without compromise. These panels are suitable for a wide range of applications, including:

- Exterior wall cladding for commercial and residential buildings

- Interior wall partitions for flexible space design

- Roofing solutions with excellent weather resistance

- Industrial applications requiring thermal insulation

Enhanced Fire Safety

Numerous aluminum sandwich boards are built with fire security in intellect. With a fire rating of Course B1 (non-combustible), these boards contribute to the generally security of buildings. The aluminum outside acts as a boundary against fire spread, whereas certain center materials can be chosen for their fire-resistant properties, guaranteeing compliance with rigid security measures in both commercial and private development.

Installation and Maintenance: Simplifying Construction Processes

The revolution brought about by aluminum sandwich panels extends beyond their physical properties to the very process of construction and long-term building maintenance:

Streamlined Installation

The installation of aluminum sandwich panels is designed to be straightforward and efficient, significantly reducing on-site labor time and costs. The process typically involves:

1.Preparing the substrate to ensure a clean and structurally sound base

2.Measuring and cutting panels to fit project specifications

3.Mounting panels using appropriate fasteners and adhesives

4.Sealing joints and edges to enhance weather resistance

This simplified installation process not only speeds up construction timelines but also minimizes the potential for errors, ensuring a high-quality finish.

Minimal Maintenance Requirements

The durability and weather resistance of aluminum sandwich panels result in significantly reduced maintenance demands throughout the building's lifecycle. Their aluminum outer layers are specifically engineered to resist corrosion, ultraviolet fading, and environmental weathering, even under harsh climate conditions. This resilience preserves both the structural integrity and visual appeal of the panels with minimal upkeep. Consequently, property owners benefit from lower long-term maintenance costs and a consistently attractive exterior that endures for decades.

Sustainability and Longevity

Aluminum sandwich boards back maintainable development through their amplified life expectancy and naturally inviting composition. Their long-term toughness decreases the recurrence of substitutions, subsequently bringing down fabric utilization and development squander. Besides, aluminum's recyclability permits the boards to be reprocessed at the conclusion of their benefit life, advancing a circular economy. Coupled with the great warm separator properties of the center fabric, these boards make strides vitality productivity and contribute to greener, more dependable building arrangements.

Conclusion

Aluminum sandwich panels have indeed revolutionized lightweight construction, offering a unique combination of strength, efficiency, and versatility. As the construction industry continues to evolve towards more sustainable and efficient practices, these panels stand at the forefront of innovative building solutions. For those looking to explore the possibilities of aluminum sandwich panels in their next project, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products tailored to your specific needs. To learn more about our exterior cladding and facade solutions, please contact us at info@sdqsc.com.