The Structural Marvels of Honeycomb Sandwich Panels in Aerospace

Unrivaled Strength-to-Weight Ratio

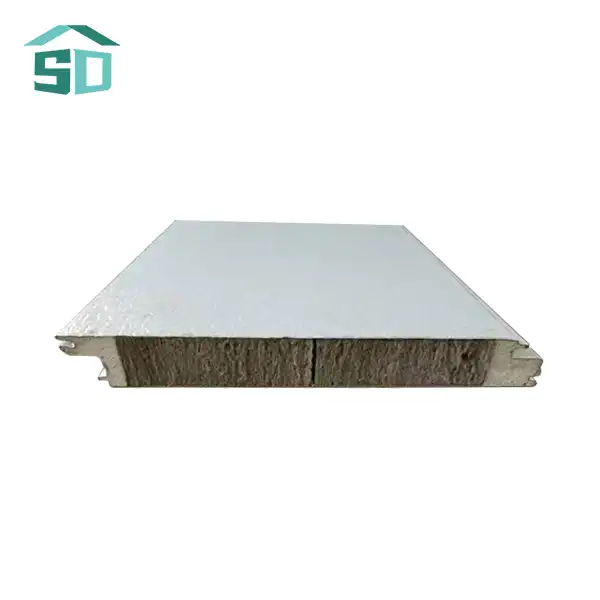

Honeycomb sandwich panels have revolutionized aerospace engineering with their remarkable strength-to-weight ratio. These panels, inspired by nature's efficient honeycomb structure, provide exceptional structural integrity while maintaining minimal weight. The core of these panels, typically made from aluminum or aramid fiber, resembles a honeycomb pattern, which distributes loads evenly across the surface. This unique design allows aerospace engineers to create lightweight yet robust components that can withstand the extreme forces experienced during flight.

The facesheets of honeycomb sandwich panels, often constructed from high-strength materials like carbon fiber or fiberglass, further enhance their structural capabilities. These thin but durable layers work in tandem with the core to resist bending and shear forces, resulting in a composite material that outperforms traditional solid materials in terms of strength and weight efficiency. This optimal balance between strength and lightness is crucial in aerospace applications, where every gram saved translates to improved fuel efficiency and increased payload capacity.

Thermal and Acoustic Insulation Properties

Beyond their structural benefits, honeycomb sandwich panels offer excellent thermal and acoustic insulation properties, making them indispensable in aerospace design. The air pockets within the honeycomb core act as natural insulators, effectively reducing heat transfer between the aircraft's interior and exterior. This thermal efficiency is particularly valuable in maintaining comfortable cabin temperatures and protecting sensitive equipment from extreme temperature fluctuations at high altitudes.

Moreover, the unique structure of honeycomb sandwich panels contributes to superior sound dampening capabilities. The panels absorb and dissipate sound waves, significantly reducing noise levels within the aircraft cabin. This acoustic insulation enhances passenger comfort on commercial flights and is crucial for communication clarity in military and space applications. By addressing both thermal and acoustic challenges, honeycomb sandwich panels play a pivotal role in creating a more comfortable and functional aerospace environment.

Applications of Honeycomb Sandwich Panels in Modern Aircraft Design

Interior Components and Cabin Furnishings

Honeycomb sandwich panels have become ubiquitous in aircraft interiors, revolutionizing the design and functionality of cabin components. These versatile panels are used extensively in flooring systems, providing a stable and lightweight foundation that can support passenger movement and seat installations. The panels' excellent strength-to-weight ratio allows for thinner floor structures, maximizing cabin space without compromising safety or comfort.

In addition to flooring, honeycomb sandwich panels are employed in various cabin furnishings, including overhead storage compartments, dividing walls, and lavatory structures. Their customizable nature allows aerospace engineers to tailor the panels' properties to specific requirements, such as fire resistance and impact absorption. The panels can be finished with a wide range of decorative laminates or veneers, enabling airlines to create aesthetically pleasing interiors that align with their brand identity while maintaining the structural benefits of honeycomb technology.

Structural Elements in Wings and Fuselage

The application of honeycomb sandwich panels extends beyond aircraft interiors to critical structural elements. In modern aircraft design, these panels play a crucial role in constructing wing components, such as flaps, ailerons, and spoilers. The panels' high stiffness and low weight contribute to improved aerodynamic performance and fuel efficiency. By replacing traditional materials with honeycomb structures, aerospace engineers can reduce the overall weight of wing assemblies while maintaining or even enhancing their structural integrity.

Honeycomb sandwich panels also find extensive use in aircraft fuselage construction. They are often incorporated into the skin of the aircraft, providing a strong, lightweight barrier that protects against external forces and environmental factors. The panels' excellent fatigue resistance and ability to withstand cyclic loading make them ideal for withstanding the repeated pressurization and depressurization cycles that aircraft experience throughout their operational life. This durability translates to reduced maintenance requirements and extended service life for aircraft components.

Advancements and Future Prospects of Honeycomb Technology in Aerospace

Innovative Materials and Manufacturing Techniques

The aerospace industry continues to push the boundaries of honeycomb sandwich panel technology through the development of innovative materials and manufacturing techniques. Advanced composite materials, such as carbon nanotubes and graphene, are being explored to further enhance the strength and lightness of honeycomb cores. These cutting-edge materials promise to deliver even greater performance benefits, potentially revolutionizing aircraft design and capabilities.

Additive manufacturing, or 3D printing, is emerging as a game-changing technology in honeycomb panel production. This advanced manufacturing method allows for the creation of complex honeycomb structures with unprecedented precision and customization. 3D-printed honeycomb cores can be optimized for specific load cases and designed with variable cell sizes and shapes, further improving their efficiency and adaptability to different aerospace applications.

Integration with Smart Technologies

The future of honeycomb sandwich panels in aerospace lies in their integration with smart technologies. Researchers are developing multifunctional panels that incorporate sensors, actuators, and energy harvesting systems directly into the honeycomb structure. These "smart" panels can provide real-time data on structural health, temperature, and pressure, enabling proactive maintenance and enhancing overall aircraft safety.

Furthermore, the incorporation of phase-change materials into honeycomb cores is being explored to create adaptive thermal management systems. These innovative panels could automatically regulate cabin temperature by absorbing or releasing heat as needed, reducing the load on aircraft environmental control systems and improving energy efficiency. As these technologies mature, honeycomb sandwich panels are poised to play an even more crucial role in the next generation of aircraft, from commercial airliners to advanced spacecraft.

Conclusion

Honeycomb sandwich panels have proven to be a transformative technology in the aerospace industry, offering unparalleled benefits in terms of strength, weight reduction, and versatility. As aerospace engineering continues to evolve, these innovative structures will undoubtedly play an increasingly important role in shaping the future of flight. From enhancing passenger comfort to improving aircraft performance and fuel efficiency, honeycomb sandwich panels are at the forefront of aerospace innovation. For more information on cutting-edge building materials and their applications in various industries, please contact us at info@sdqsc.com.