Understanding the Structural Composition: Honeycomb vs Foam Core

The Intricate Architecture of Honeycomb Sandwich Panels

Honeycomb sandwich panels are marvels of engineering, designed to maximize strength while minimizing weight. At their core lies a hexagonal structure reminiscent of a bee's honeycomb, hence the name. This core is typically made from aluminum, nomex, or other lightweight materials. The honeycomb is then sandwiched between two face sheets, which can be composed of various materials such as aluminum, steel, or fiber-reinforced composites.

The unique structure of honeycomb sandwich panels provides several advantages. The hexagonal cells create a network of interconnected supports, distributing loads evenly across the panel. This design allows for exceptional strength-to-weight ratios, making these panels ideal for applications where weight is a critical factor, such as in aerospace or marine industries.

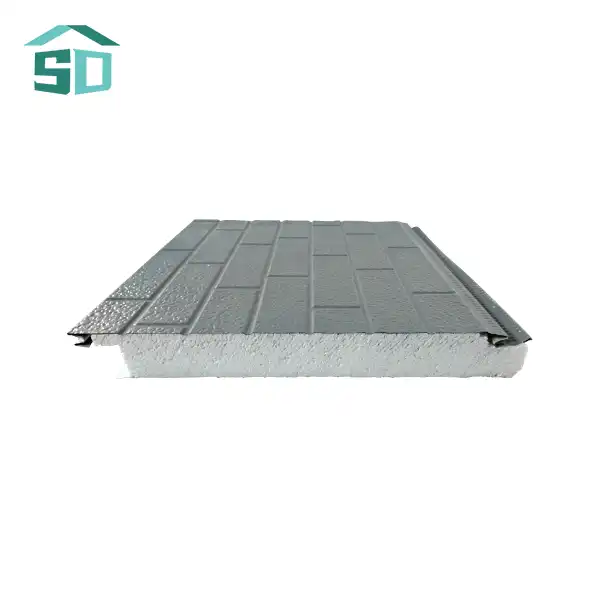

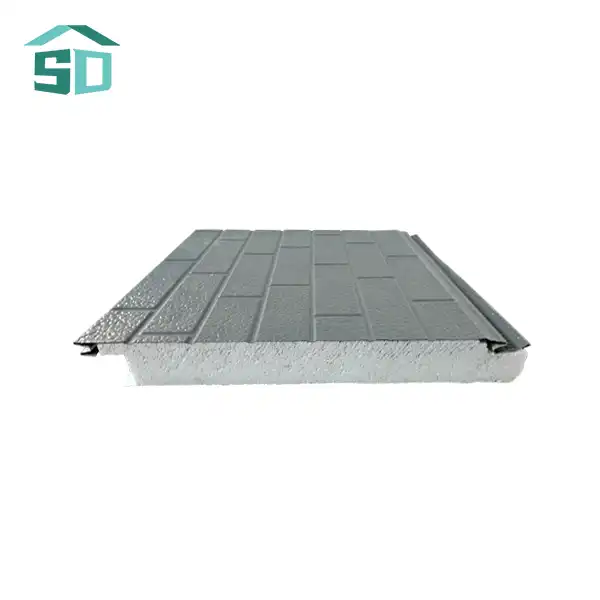

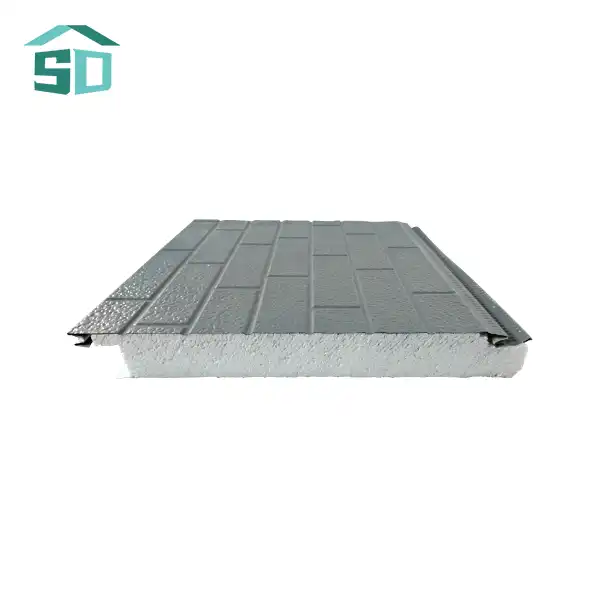

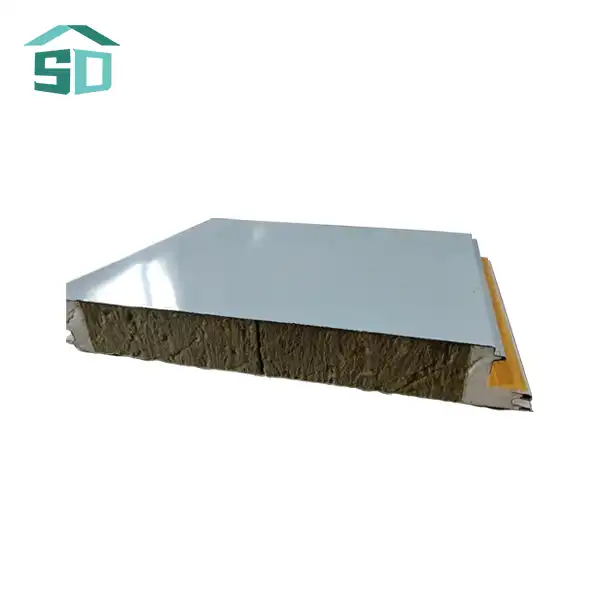

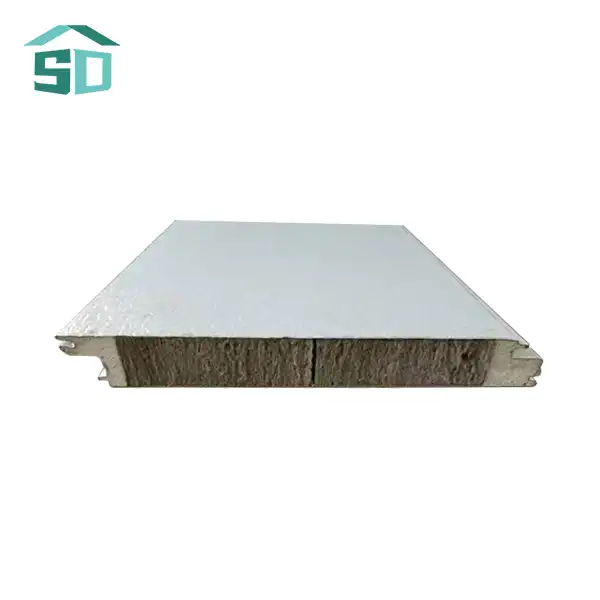

The Composition of Foam Core Panels

In contrast, foam core panels consist of a layer of foam insulation sandwiched between two face sheets. The foam core is typically made from materials like polyurethane, polystyrene, or polyisocyanurate. While these panels offer good insulation properties, they lack the structural integrity provided by the honeycomb design.

Foam core panels are generally lighter than honeycomb sandwich panels, but this comes at the cost of reduced strength and durability. They are more susceptible to crushing or deformation under heavy loads, which can limit their applications in certain scenarios.

Performance Comparison: Strength, Insulation, and Durability

Unparalleled Strength of Honeycomb Sandwich Panels

When it comes to structural integrity, honeycomb sandwich panels reign supreme. The honeycomb core provides exceptional resistance to compression and shear forces, allowing these panels to maintain their shape and strength even under significant loads. This makes them ideal for applications in construction, where they can be used to reinforce walls, ceilings, and floors without adding excessive weight to the structure.

Moreover, the strength-to-weight ratio of honeycomb sandwich panels is unmatched. They offer the same strength as solid materials at a fraction of the weight, making them a popular choice in industries where weight reduction is crucial, such as aerospace and automotive manufacturing.

Insulation Capabilities: A Close Contest

Both honeycomb sandwich panels and foam core panels offer excellent insulation properties, but they achieve this in different ways. Honeycomb sandwich panels rely on the air trapped within their hexagonal cells to provide insulation. This design not only offers thermal insulation but also provides acoustic damping properties.

Foam core panels, on the other hand, derive their insulation capabilities from the foam material itself. Depending on the type of foam used, these panels can offer excellent R-values, making them effective at reducing heat transfer. However, the insulation performance of foam core panels can degrade over time, especially if the foam becomes damaged or compressed.

Longevity and Durability: The Honeycomb Advantage

When it comes to durability, honeycomb sandwich panels have a clear edge. The honeycomb structure is inherently resistant to fatigue, meaning these panels can withstand repeated stress cycles without losing their structural integrity. This makes them ideal for applications where long-term performance is crucial.

Additionally, honeycomb sandwich panels offer superior resistance to environmental factors. Many are designed with corrosion-resistant materials, allowing them to withstand harsh conditions without deteriorating. This resilience translates to lower maintenance costs and a longer lifespan compared to foam core panels.

Versatility and Applications: Where Each Panel Excels?

The Multi-Faceted Nature of Honeycomb Sandwich Panels

Honeycomb sandwich panels shine in their versatility. Their combination of strength, lightweight design, and insulation properties makes them suitable for a wide range of applications. In the construction industry, they're used for both interior and exterior wall enhancements, offering improved structural integrity without significantly increasing the building's weight.

These panels are also widely used in the transportation sector. In aircraft, they're used for flooring, walls, and even in the construction of wings and fuselage sections. In the automotive industry, honeycomb panels find applications in body panels, floors, and interior components, contributing to vehicle weight reduction and improved fuel efficiency.

Niche Applications of Foam Core Panels

While foam core panels may not match the structural strength of honeycomb panels, they excel in certain niche applications. Their lightweight nature and good insulation properties make them ideal for use in refrigerated trucks and containers, where maintaining a consistent temperature is crucial.

Foam core panels are also commonly used in the construction of temporary structures or in situations where thermal insulation is the primary concern. They're often employed in the creation of insulated doors, partition walls, and in some cases, as insulation in roofing systems.

Aesthetic Considerations and Customization

Both honeycomb sandwich panels and foam core panels offer customization options, but honeycomb panels often provide more flexibility. The face sheets of honeycomb panels can be finished in a variety of colors and textures, allowing for greater aesthetic control. Some manufacturers even offer the option to print custom designs directly onto the panels, opening up a world of creative possibilities for architects and designers.

Foam core panels, while also customizable to some extent, generally offer fewer options in terms of finishes and designs. This can limit their use in projects where aesthetic appeal is a primary consideration.

Conclusion

While both honeycomb sandwich panels and foam core panels have their place in the construction and manufacturing industries, honeycomb panels often emerge as the more versatile and high-performance option. Their unique combination of strength, lightweight design, insulation properties, and customization options make them an excellent choice for a wide range of applications.

Whether you're working on a construction project, designing a vehicle, or looking for innovative ways to enhance structural integrity, honeycomb sandwich panels deserve serious consideration. For more information about our range of honeycomb sandwich panels and how they can benefit your project, don't hesitate to reach out to us at info@sdqsc.com. Our team of experts is always ready to help you find the perfect solution for your specific needs.