- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

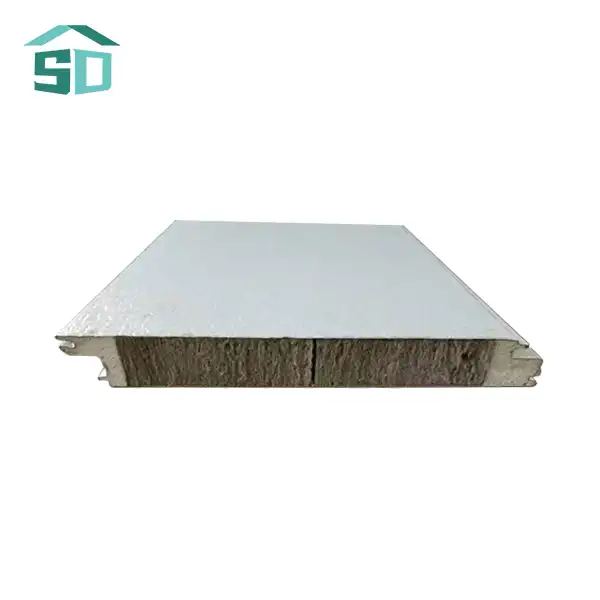

High-Quality PU Insulated Sandwich Panels for Construction

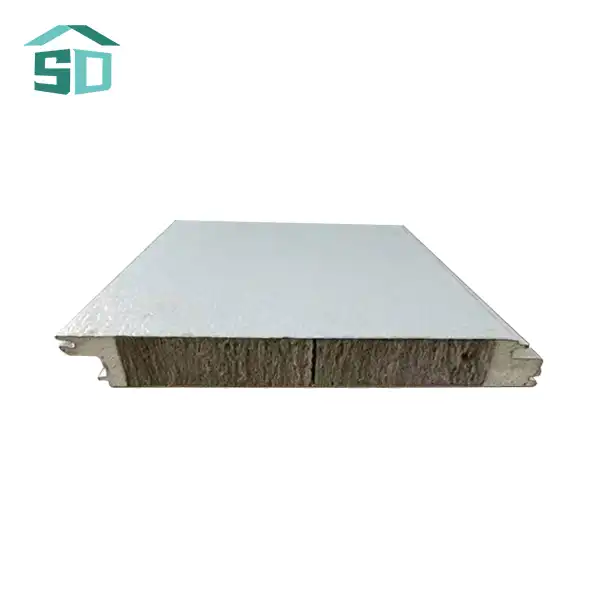

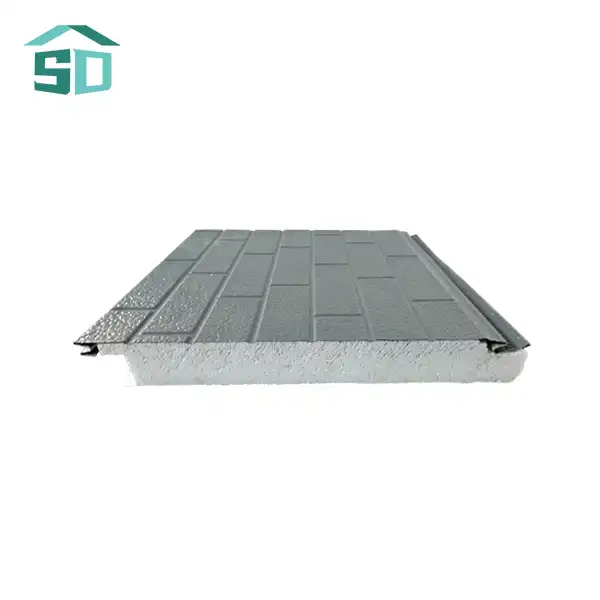

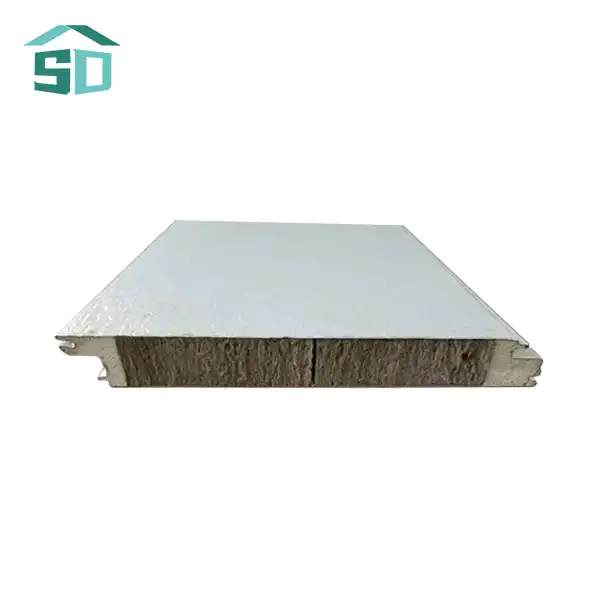

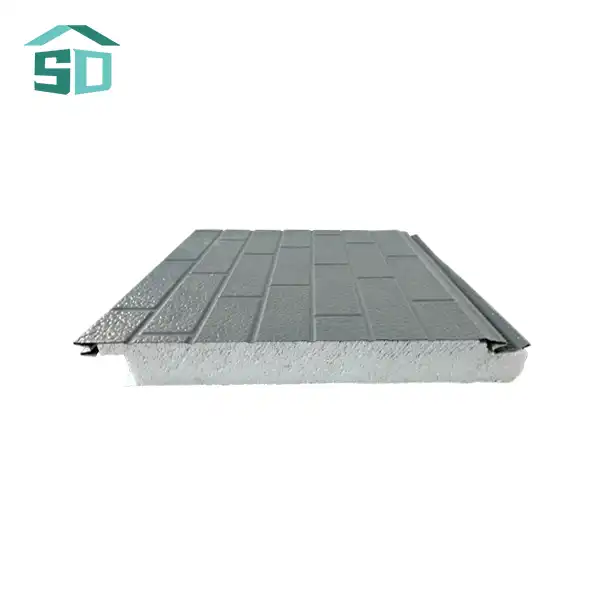

High-quality PU insulated sandwich panels have revolutionized the construction industry by offering a versatile and efficient solution for building envelopes. These panels, composed of a polyurethane (PU) core sandwiched between two metal sheets, provide superior thermal insulation, structural integrity, and aesthetic appeal. With their excellent energy efficiency, durability, and ease of installation, PU insulated sandwich panels have become a preferred choice for architects, builders, and property owners seeking to create high-performance, sustainable structures. From residential complexes to commercial buildings, these panels offer a perfect blend of functionality and design flexibility, making them an indispensable component in modern construction projects.

The Anatomy of PU Insulated Sandwich Panels: Unraveling Their Composition and Benefits

Core Components and Structure

PU insulated sandwich panels are engineered marvels that combine simplicity with high performance. At their heart lies a polyurethane foam core, renowned for its exceptional insulating properties. This core is encased between two metal sheets, typically made of aluminum, steel, or stainless steel, creating a robust and lightweight composite structure.

The polyurethane core is the key to the panel's impressive thermal performance. With a thermal conductivity of ≤ 0.023 W/mK, these panels offer superior insulation compared to traditional building materials. This low thermal conductivity translates to significant energy savings in heating and cooling, making PU insulated sandwich panels an eco-friendly choice for modern construction.

Customizable Dimensions for Versatile Applications

One of the standout features of PU insulated sandwich panels is their adaptability to various project requirements. These panels are available in a range of thicknesses, typically 50mm, 75mm, and 100mm, with custom sizes available to meet specific needs. The width options of 1,000mm, 1,200mm, and 1,500mm provide flexibility in coverage, while the customizable length of up to 12,000mm allows for seamless application in large-scale projects.

This dimensional versatility makes PU insulated sandwich panels suitable for a wide array of construction applications, from residential complexes and office buildings to industrial facilities and cold storage units. The ability to tailor panel dimensions ensures optimal fit and minimal waste, contributing to both cost-effectiveness and sustainability in construction projects.

Surface Treatments and Aesthetic Options

Beyond their functional benefits, PU insulated sandwich panels offer extensive aesthetic possibilities. The exterior metal sheets can be coated, painted, or anodized to achieve the desired look and feel. This flexibility in surface treatment allows architects and designers to create visually striking facades that complement the overall architectural vision.

From sleek, modern finishes to textured, rustic appearances, the design options are virtually limitless. The ability to customize colors and patterns enables these panels to enhance any décor, making them a favorite among architects looking to balance form with function in their designs.

Performance Metrics: Understanding the Technical Prowess of PU Insulated Sandwich Panels

Thermal Efficiency and Energy Conservation

The thermal performance of PU insulated sandwich panels is nothing short of remarkable. With a thermal conductivity of ≤ 0.023 W/mK, these panels create a formidable barrier against heat transfer. This exceptional insulation capability translates to significant reductions in energy consumption for heating and cooling, making buildings more energy-efficient and environmentally friendly.

In practical terms, this means that structures utilizing PU insulated sandwich panels can maintain comfortable interior temperatures with less reliance on HVAC systems. The result is not only lower energy bills but also a reduced carbon footprint, aligning with global efforts towards sustainable construction practices.

Acoustic Performance and Sound Insulation

Beyond thermal insulation, PU insulated sandwich panels also excel in acoustic performance. With sound insulation capabilities of up to 30dB, these panels significantly reduce noise transmission between interior and exterior environments. This acoustic barrier is particularly valuable in urban settings or near high-traffic areas, where noise pollution can be a significant concern.

The sound-dampening properties of PU insulated sandwich panels contribute to creating more peaceful and productive indoor environments. Whether in residential complexes, offices, or educational institutions, this acoustic benefit enhances the overall quality of life for occupants.

Fire Safety and Flame Retardancy

Safety is paramount in construction, and PU insulated sandwich panels meet rigorous fire safety standards. Available in Class B1 and Class A2 fire ratings, these panels offer robust fire resistance, contributing to the overall safety of the building and its occupants.

The flame-retardant properties of PU insulated sandwich panels provide crucial time for evacuation in the event of a fire, making them an essential component in fire safety strategies. This feature is particularly valuable in high-rise buildings, industrial facilities, and other structures where fire safety is a critical concern.

Weather Resistance and Durability

PU insulated sandwich panels are engineered to withstand harsh environmental conditions. Their waterproof and moisture-resistant properties prevent water infiltration, protecting the building's interior from dampness and potential water damage. This moisture resistance also contributes to the longevity of the structure by preventing issues like mold growth and material degradation.

The panels' durability extends to their ability to resist corrosion and withstand extreme weather conditions. This resilience ensures that buildings maintain their structural integrity and appearance over time, reducing maintenance costs and extending the lifespan of the structure.

Application Versatility: Exploring the Wide-Ranging Uses of PU Insulated Sandwich Panels

Residential Construction: Comfort and Efficiency

In residential construction, PU insulated sandwich panels are transforming the way homes are built and insulated. Their superior thermal performance ensures comfortable living spaces year-round, while their acoustic properties create peaceful environments even in bustling urban settings. The panels' lightweight nature allows for quicker construction times, reducing labor costs and accelerating project timelines.

Commercial and Industrial Applications: Functionality Meets Design

The versatility of PU insulated sandwich panels shines in commercial and industrial applications. Office buildings, retail spaces, and warehouses benefit from the panels' energy efficiency and low maintenance requirements. In industrial settings, these panels are particularly valuable for creating temperature-controlled environments, such as cold storage facilities and clean rooms.

Specialized Structures: From Cold Storage to Modular Buildings

PU insulated sandwich panels find specialized applications in various niche sectors. In the food industry, they are essential for creating efficient cold storage facilities that maintain precise temperatures. The panels' excellent insulation properties help minimize energy consumption in these energy-intensive environments.

Conclusion

High-quality PU insulated sandwich panels represent a significant leap forward in construction technology, offering a perfect blend of performance, efficiency, and design flexibility. Their superior insulation properties, coupled with durability and ease of installation, make them an invaluable asset in modern construction projects across various sectors.

For those looking to leverage the benefits of PU insulated sandwich panels in their next construction project, Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality options. With our commitment to innovation and quality, we provide solutions that meet the diverse needs of modern construction. To learn more about our PU insulated sandwich panels and other exterior cladding solutions, please contact us at info@sdqsc.com.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). (2021). ASHRAE Handbook - Fundamentals.

2. International Code Council. (2021). International Building Code (IBC).

3. U.S. Department of Energy. (2022). Building Energy Codes Program.

4. European Committee for Standardization. (2019). EN 14509: Self-supporting double skin metal faced insulating panels - Factory made products - Specifications.

5. National Fire Protection Association. (2021). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.