The Anatomy of Glass Wool Sandwich Panels: A Closer Look at Their Composition

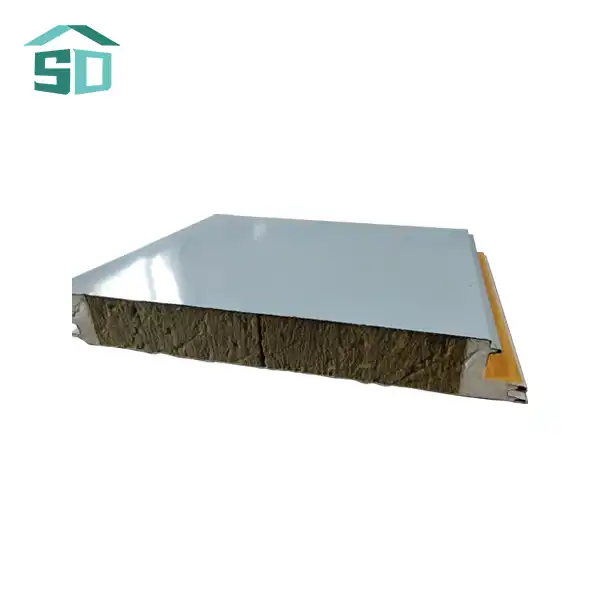

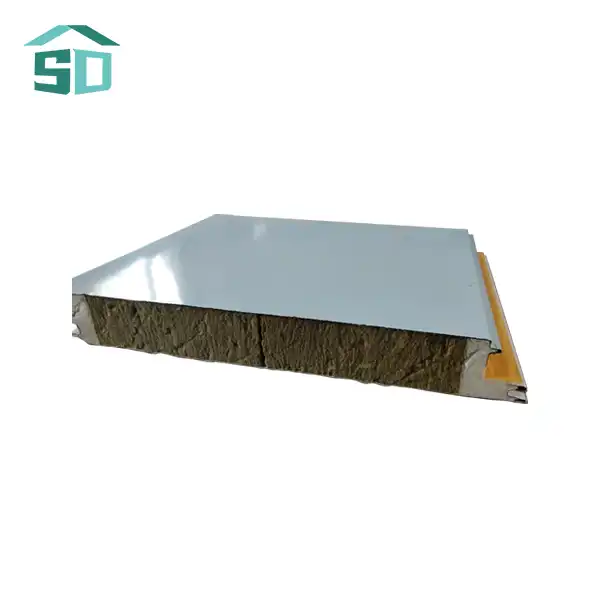

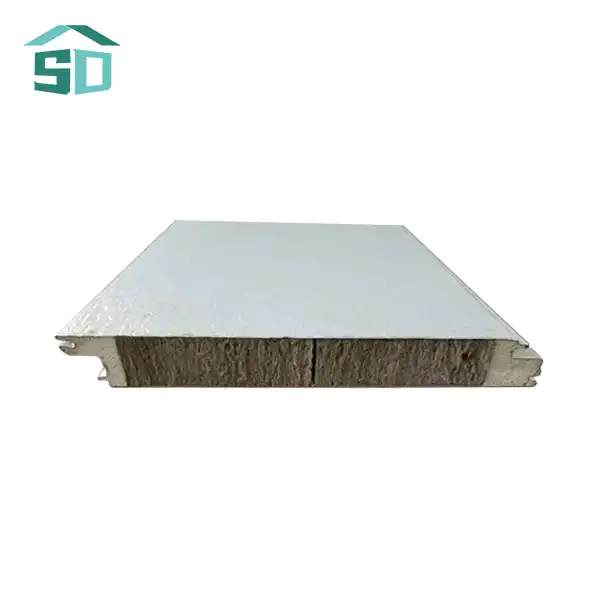

Core Material: The Heart of Insulation

At the center of every Glass Wool Sandwich Panel lies its most crucial component - the glass wool core. This innovative material is engineered to provide superior insulation properties, making it the backbone of the panel's thermal performance. Glass wool, composed of fine fibers of glass arranged into a texture similar to wool, traps air within its structure, significantly reducing heat transfer.

The density of the glass wool core in these panels typically ranges from 64kg/m³ to 100kg/m³, striking an optimal balance between insulation efficiency and structural integrity. This carefully calibrated density ensures that the panels maintain their shape and performance over time, even under varying environmental conditions.

One of the standout features of glass wool is its impressive thermal conductivity rating of ≤ 0.043 W/m·K. This low thermal conductivity translates to exceptional insulation properties, helping to maintain comfortable indoor temperatures while reducing energy consumption for heating and cooling systems.

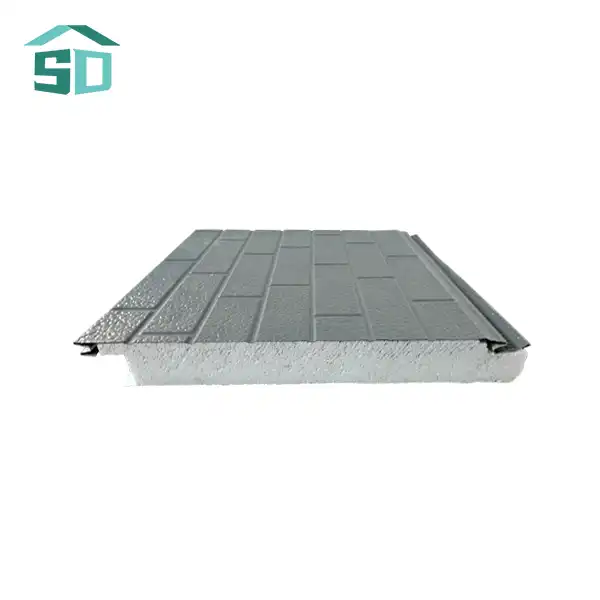

Outer Layers: Strength and Aesthetics Combined

The outer layers of Glass Wool Sandwich Panels are typically crafted from either galvanized steel or aluminum. These materials are chosen for their durability, corrosion resistance, and aesthetic versatility. The metal facing not only protects the insulation core but also provides the structural strength necessary for the panel's load-bearing capabilities.

Galvanized steel offers robust durability and excellent resistance to environmental factors, making it ideal for exterior applications. Aluminum, on the other hand, provides a lightweight alternative that's particularly suitable for projects where weight is a critical consideration.

Dimensions and Customization

Glass Wool Sandwich Panels are available in a range of standard thicknesses, including 50mm, 75mm, 100mm, and 150mm. This variety allows builders to select the optimal thickness based on the specific insulation requirements of their project. The standard width of these panels is 1,000mm, providing a convenient size for installation and coverage.

One of the key advantages of these panels is the ability to customize their length based on project needs. This flexibility ensures that the panels can be tailored to fit the exact specifications of any construction project, minimizing waste and simplifying installation.

Unparalleled Performance: The Multifaceted Benefits of Glass Wool Sandwich Panels

Thermal Efficiency: A New Standard in Insulation

The primary function of Glass Wool Sandwich Panels is to provide superior thermal insulation, and they excel in this aspect. The glass wool core, with its low thermal conductivity, creates an effective barrier against heat transfer. This high-performance insulation helps maintain consistent indoor temperatures, reducing the load on HVAC systems and subsequently lowering energy costs.

In climates with extreme temperature variations, these panels prove particularly valuable. They help keep interiors cool during hot summers and warm during cold winters, contributing to year-round comfort and energy efficiency. This thermal performance not only enhances occupant comfort but also aligns with increasingly stringent energy efficiency standards in the construction industry.

Fire Safety: Inherent Flame Resistance for Peace of Mind

Fire safety is a critical concern in any construction project, and Glass Wool Sandwich Panels address this issue head-on. These panels boast a fire resistance rating of A1, classifying them as non-combustible. This rating is the highest possible in fire safety classifications, providing assurance to builders and occupants alike.

The non-combustible nature of glass wool means that it does not contribute to the spread of fire. In the event of a fire, these panels can help contain the blaze, potentially buying crucial time for evacuation and firefighting efforts. This inherent fire resistance makes Glass Wool Sandwich Panels an excellent choice for buildings where fire safety is a top priority, such as high-rise structures, schools, and healthcare facilities.

Acoustic Performance: Creating Quieter Spaces

Beyond thermal insulation and fire safety, Glass Wool Sandwich Panels also offer impressive acoustic properties. With a Noise Reduction Coefficient (NRC) of 0.85, these panels are highly effective at absorbing sound. This characteristic makes them ideal for creating quieter indoor environments, whether in office spaces, educational institutions, or residential buildings.

The sound-absorbing qualities of glass wool help reduce echo and reverberation within spaces, improving overall acoustic comfort. In multi-story or multi-unit buildings, these panels can significantly reduce sound transmission between floors or adjacent units, enhancing privacy and livability.

Versatility and Applications: Glass Wool Sandwich Panels in Modern Construction

Exterior Cladding: Enhancing Building Envelopes

One of the primary applications of Glass Wool Sandwich Panels is as exterior cladding. In this role, they serve as a protective and insulating envelope for buildings. The durable outer layers of galvanized steel or aluminum provide excellent resistance to weathering, UV radiation, and other environmental factors, ensuring long-lasting performance.

As exterior cladding, these panels contribute to the overall energy efficiency of buildings by creating a well-insulated building envelope. They also offer architects the flexibility to create visually striking facades, with options for various colors, textures, and finishes. This versatility allows for the creation of unique architectural expressions while maintaining high performance standards.

Interior Partitions: Maximizing Space Efficiency

While often associated with exterior applications, Glass Wool Sandwich Panels are equally effective as interior partitions. Their excellent acoustic properties make them ideal for creating quiet, private spaces within open-plan environments. In office settings, these panels can be used to construct meeting rooms or individual workspaces that offer both visual and acoustic privacy.

The lightweight nature of these panels, particularly those with aluminum facings, makes them easy to install and reconfigure as needed. This flexibility is valuable in dynamic environments where space requirements may change over time. Additionally, the smooth, finished surfaces of these panels contribute to a clean, modern aesthetic in interior spaces.

Specialized Applications: From Cold Storage to Clean Rooms

The unique properties of Glass Wool Sandwich Panels make them suitable for a range of specialized applications. In cold storage facilities, for instance, their superior insulation properties help maintain consistent low temperatures while minimizing energy consumption. The non-porous nature of the panels also makes them resistant to moisture and mold growth, critical factors in food storage environments.

In clean room applications, such as in pharmaceutical or electronic manufacturing facilities, these panels offer the dual benefits of insulation and cleanability. The smooth, non-porous surfaces can be easily sanitized, helping to maintain the stringent cleanliness standards required in these environments.

Conclusion

Glass Wool Sandwich Panels represent a significant advancement in construction technology, offering a unique combination of thermal efficiency, fire safety, acoustic performance, and versatility. As the construction industry continues to evolve, with an increasing focus on energy efficiency, sustainability, and occupant comfort, these panels are poised to play an even more crucial role in shaping the buildings of the future.

For more information on how Glass Wool Sandwich Panels can benefit your next construction project, or to explore our range of exterior cladding and facade solutions, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.