The Science Behind Green Thermal Insulation Panels

Green thermal insulation panels are engineered to maximize energy efficiency through a combination of advanced materials and innovative design. At their core, these panels utilize natural or recycled materials that possess inherent insulating properties. Common eco-friendly insulation materials include recycled denim, sheep's wool, cellulose, and even soybean-based foams. These materials are chosen for their ability to trap air and create a barrier against heat transfer.

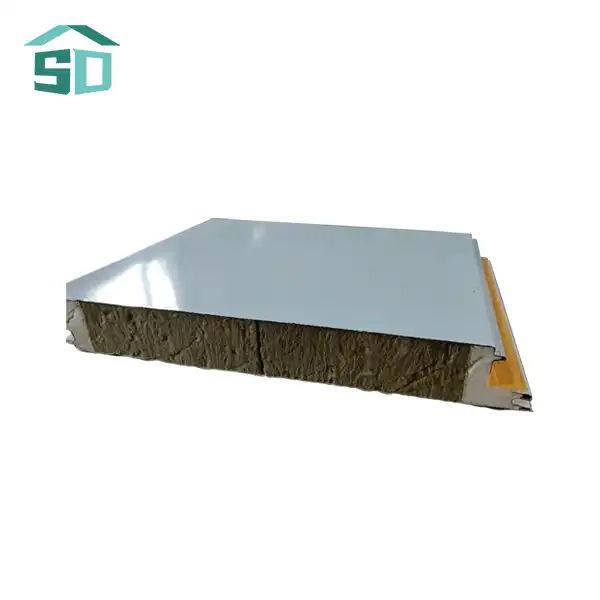

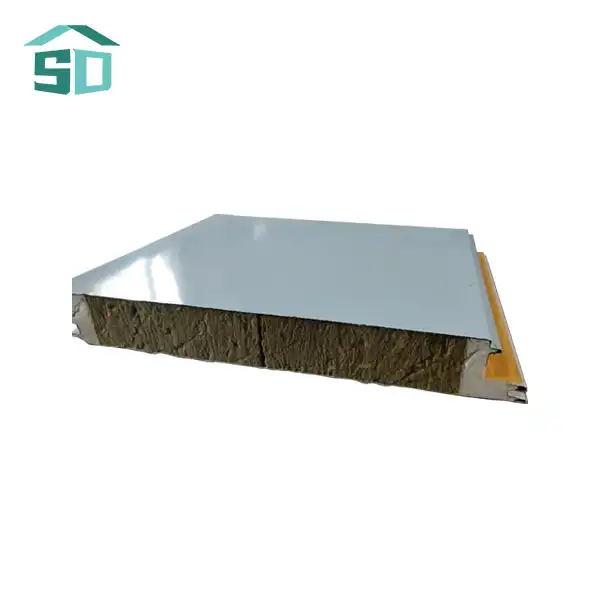

The effectiveness of green thermal insulation panels lies in their multi-layered structure. Typically, they consist of an outer layer made from durable, weather-resistant materials such as aluminum or steel, which can be customized in various colors and textures to suit architectural preferences. This exterior layer not only provides aesthetic appeal but also serves as the first line of defense against environmental elements.

Innovative Insulation Materials

The insulation layer within green thermal panels is where the magic happens. Materials like polyurethane, polystyrene, rock wool, and glass wool are carefully selected for their superior insulating properties. These materials create a network of tiny air pockets that significantly slow down heat transfer. The thickness of this layer can range from 50mm to 200mm, allowing for customization based on specific insulation requirements.

What sets green thermal insulation panels apart is their use of eco-friendly versions of these materials. For instance, bio-based polyurethane foams derived from renewable resources offer comparable insulation performance to their petroleum-based counterparts while reducing reliance on fossil fuels. Similarly, recycled glass and stone wool products provide excellent insulation while diverting waste from landfills.

Advanced Manufacturing Processes

The production of green thermal insulation panels involves state-of-the-art manufacturing processes that prioritize efficiency and sustainability. Advanced production lines incorporate strict quality control measures, ensuring that each panel meets rigorous standards for thickness, mechanical strength, and fire resistance. The panels undergo comprehensive inspections, including tests for paint film thickness and product appearance, to guarantee both performance and aesthetic quality.

Moreover, manufacturers are increasingly adopting closed-loop production systems that minimize waste and energy consumption. By recycling production byproducts and implementing energy-efficient manufacturing techniques, the overall environmental impact of panel production is significantly reduced.

Benefits and Applications of Green Thermal Insulation Panels

The adoption of green thermal insulation panels offers a multitude of benefits for building owners, occupants, and the environment. These panels excel in energy efficiency, substantially reducing heat loss and gain. This translates to buildings that stay warm in winter and cool in summer, resulting in lower heating and cooling costs. The superior insulation properties of these panels contribute to a more stable indoor climate, enhancing comfort for occupants.

Sustainability is a key advantage of green thermal insulation panels. Made from recyclable and often recycled materials, these panels play a crucial role in green building initiatives. They can help projects achieve energy-efficient certifications, such as LEED or BREEAM, which are increasingly valuable in today's environmentally conscious market.

Versatility in Application

Green thermal insulation panels demonstrate remarkable versatility, finding applications across various building types and construction projects. In residential settings, they can be used for exterior walls, providing both insulation and aesthetic appeal. Commercial and industrial buildings benefit from their use in roof insulation, significantly improving overall energy efficiency.

These panels are particularly well-suited for retrofitting historic buildings, offering a way to improve energy performance without compromising architectural integrity. Their application extends to municipal buildings, security kiosks, and even garden structures, showcasing their adaptability to diverse architectural needs.

Performance and Durability

One of the most compelling aspects of green thermal insulation panels is their long-term performance. Engineered for durability, these panels resist harsh weather conditions, including UV radiation and moisture. This resilience ensures that their insulating properties remain effective over time, providing a sustainable solution for temperature regulation.

Fire safety is another critical feature of these panels. Many achieve a Class A fire rating, offering peace of mind to building owners and occupants. This fire resistance is crucial in both residential and commercial applications, contributing to overall building safety.

Installation and Maintenance of Green Thermal Insulation Panels

The installation process for green thermal insulation panels is designed to be straightforward, allowing for efficient implementation in both new construction and retrofit projects. The process typically begins with thorough preparation of the wall surface, ensuring it is clean and free of debris. Accurate measurements are crucial to determine the appropriate panel sizes needed for the project.

Securing the panels involves using specialized fasteners that are compatible with the panel material and the underlying structure. These fasteners ensure a tight fit against the surface, maximizing the insulation's effectiveness. The final step involves sealing edges and joints, which is critical for enhancing both thermal performance and aesthetics.

Customization Options

Green thermal insulation panels offer extensive customization options, allowing architects and designers to achieve both functional and aesthetic goals. The panels can be tailored in size to fit specific project requirements, with thicknesses ranging from 50mm to 200mm to meet varying insulation needs. Color options are diverse, with panels available in various coated and anodized finishes to complement any architectural style.

This level of customization extends to the insulation material itself. Depending on the specific requirements of the project, installers can choose between different types of eco-friendly insulation, such as polyurethane, polystyrene, rock wool, or glass wool. Each material offers unique benefits in terms of thermal performance, sound insulation, and environmental impact.

Maintenance and Longevity

One of the key advantages of green thermal insulation panels is their low maintenance requirements. The durable outer layer, typically made of aluminum or steel, is designed to withstand environmental stressors, including UV radiation and corrosion. This resilience means that the panels maintain their appearance and performance with minimal upkeep.

Regular inspections are recommended to ensure the integrity of seals and joints, which are crucial for maintaining optimal insulation performance. In the rare event that a panel needs replacement or repair, the modular nature of these systems allows for easy targeted interventions without disrupting the entire façade.

The longevity of green thermal insulation panels contributes significantly to their sustainability profile. By maintaining their performance over extended periods, these panels reduce the need for frequent replacements, thereby minimizing waste and resource consumption in the long term.

Conclusion

Green thermal insulation panels represent a significant advancement in sustainable building technology, offering a perfect blend of energy efficiency, environmental responsibility, and aesthetic versatility. As the construction industry continues to evolve towards more eco-friendly practices, these panels stand out as a crucial component in creating buildings that are not only comfortable and energy-efficient but also environmentally sustainable.

The benefits of green thermal insulation panels extend beyond individual buildings, contributing to broader goals of reducing energy consumption and mitigating climate change. As awareness of environmental issues grows, the demand for such innovative and sustainable building solutions is likely to increase, positioning green thermal insulation panels at the forefront of modern construction practices.

For those interested in exploring how green thermal insulation panels can enhance their building projects, expert guidance is available. To learn more about these innovative solutions and how they can be integrated into your next construction or renovation project, please contact us at info@sdqsc.com. Our team of specialists is ready to provide detailed information and tailored advice to meet your specific needs.

FAQ

What makes green thermal insulation panels different from traditional insulation?

Green thermal insulation panels use eco-friendly materials and manufacturing processes, offering superior energy efficiency while minimizing environmental impact.

Can green thermal insulation panels be used in both residential and commercial buildings?

Yes, these panels are versatile and can be applied in various settings, including homes, offices, and industrial facilities.

How do green thermal insulation panels contribute to energy savings?

They provide excellent insulation, reducing heat loss in winter and heat gain in summer, thereby lowering energy costs for heating and cooling.

References

1.U.S. Department of Energy. (2023). Insulation.

2.Environmental Protection Agency. (2022). Green Building.

3.International Energy Agency. (2023). Buildings: A source of enormous untapped efficiency potential.