- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Glass Wool Sandwich Panels for Superior Insulation in Warehouses & Factories

Glass Wool Sandwich Panels have emerged as a game-changing solution for superior insulation in warehouses and factories. These innovative panels combine durability, thermal efficiency, and fire safety, making them an ideal choice for industrial facilities. With their glass wool core and customizable outer layers, these panels offer unparalleled performance in maintaining optimal temperatures, reducing energy costs, and enhancing overall building safety.

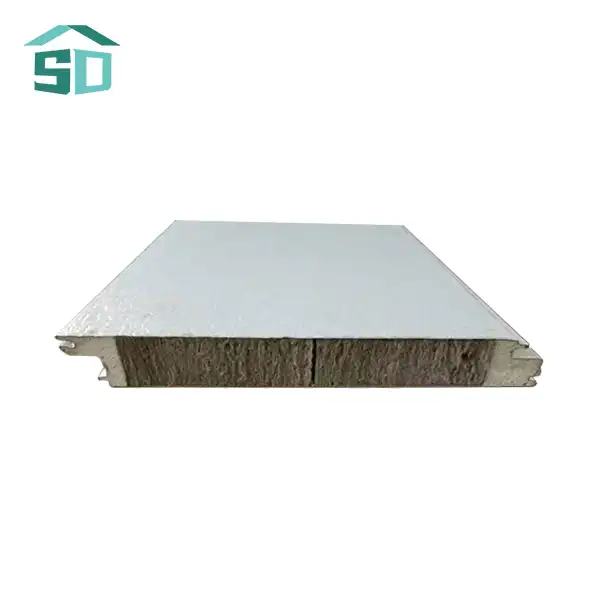

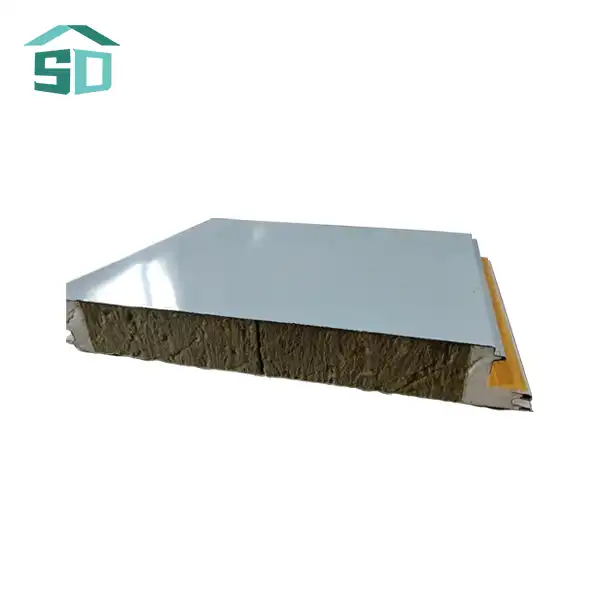

The Anatomy of Glass Wool Sandwich Panels: Engineering Excellence

Core Composition: The Power of Glass Wool

At the heart of Glass Wool Sandwich Panels lies their exceptional core material: glass wool. This ingenious insulation medium is crafted from recycled glass fibers, meticulously woven into a dense, yet lightweight mat. The unique structure of glass wool creates countless microscopic air pockets, effectively trapping heat and sound waves. This intrinsic property is the key to the panel's remarkable thermal and acoustic insulation capabilities.

The density of the glass wool core in these panels typically ranges from 64kg/m³ to 100kg/m³, striking an optimal balance between insulation performance and structural integrity. This carefully calibrated density ensures that the panels maintain their shape and effectiveness over time, even under the rigorous demands of industrial environments.

Outer Layer Materials: Strength Meets Aesthetics

Encasing the glass wool core are robust outer layers, typically fashioned from either galvanized steel or aluminum. These materials are chosen for their durability, corrosion resistance, and aesthetic versatility. The galvanized steel option provides exceptional strength and longevity, making it particularly suitable for harsh industrial settings. Aluminum, on the other hand, offers a lighter weight alternative without compromising on durability, and is often preferred in applications where weight considerations are paramount.

These outer layers not only protect the insulation core but also serve as the visible face of the panel. They can be customized with a wide array of colors and finishes, allowing architects and designers to create visually appealing facades that complement the overall aesthetic of the building. This blend of functionality and design flexibility makes Glass Wool Sandwich Panels a favorite among professionals seeking to balance performance with architectural vision.

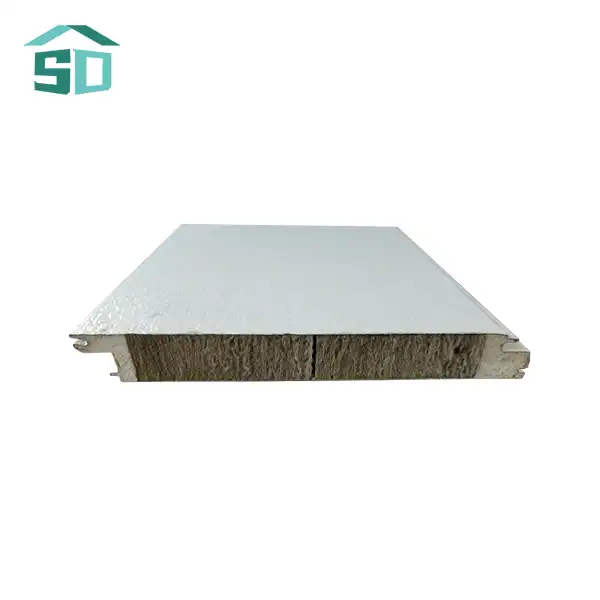

Dimensional Flexibility: Tailored to Your Needs

One of the most advantageous features of Glass Wool Sandwich Panels is their dimensional flexibility. These panels are available in a range of thicknesses, typically including 50mm, 75mm, 100mm, and 150mm options. This variety allows builders to select the ideal thickness based on the specific insulation requirements of their project, climate considerations, and local building codes.

While the standard width of these panels is 1,000mm, providing efficient coverage and ease of installation, the length can be customized to meet the unique needs of each project. This adaptability ensures minimal waste during installation and allows for seamless integration with various building designs and structural layouts.

Unparalleled Performance: Why Glass Wool Sandwich Panels Excel in Industrial Settings

Thermal Efficiency: A New Standard in Energy Conservation

The thermal performance of Glass Wool Sandwich Panels is nothing short of impressive. With a thermal conductivity rating of ≤ 0.043 W/m·K, these panels create a formidable barrier against heat transfer. This exceptional insulation capability translates to significant energy savings in both heating and cooling, a critical factor in the operational efficiency of warehouses and factories.

In cold climates, the panels effectively retain heat within the building, reducing the load on heating systems. Conversely, in warmer environments, they prevent the infiltration of external heat, easing the burden on air conditioning units. This bi-directional insulation property ensures year-round comfort and energy efficiency, regardless of the external temperature fluctuations.

Fire Safety: Non-Combustible Protection

Safety is paramount in industrial settings, and Glass Wool Sandwich Panels excel in this regard. These panels boast an A1 fire resistance rating, classifying them as non-combustible. This superior fire safety feature is crucial in warehouses and factories, where the risk of fire can be elevated due to the nature of operations or stored materials.

The non-combustible nature of glass wool not only prevents the spread of fire but also does not contribute to the production of toxic fumes in the event of a fire. This dual benefit can be life-saving, providing valuable time for evacuation and fire suppression efforts. The peace of mind that comes with such robust fire safety measures is invaluable for business owners, employees, and insurance providers alike.

Acoustic Excellence: Noise Reduction for Enhanced Productivity

Industrial environments are often plagued by high noise levels, which can impact worker productivity and well-being. Glass Wool Sandwich Panels address this challenge with their impressive sound absorption capabilities, boasting a Noise Reduction Coefficient (NRC) of 0.85. This means that 85% of the sound energy that hits the panel is absorbed rather than reflected back into the space.

The acoustic benefits of these panels are twofold. Internally, they help create a more comfortable working environment by reducing echo and reverberation within large warehouse or factory spaces. Externally, they act as an effective sound barrier, minimizing the transmission of industrial noise to surrounding areas. This acoustic performance can be particularly beneficial for facilities located near residential areas or other noise-sensitive locations.

Practical Applications: Maximizing the Potential of Glass Wool Sandwich Panels

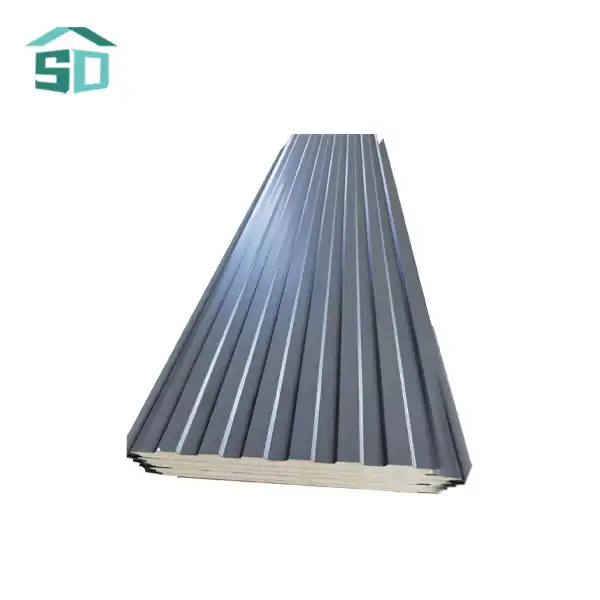

Versatile Installation: From Walls to Roofs

The versatility of Glass Wool Sandwich Panels extends beyond their customizable dimensions and aesthetic options. These panels are equally effective when used in wall or roof applications, providing a comprehensive insulation solution for the entire building envelope. Their lightweight nature, compared to traditional construction materials, allows for easier handling and installation, potentially reducing construction time and labor costs.

Retrofit Solutions: Upgrading Existing Structures

Glass Wool Sandwich Panels are not limited to new construction projects. They offer an excellent solution for retrofitting existing warehouses and factories that may be struggling with poor insulation or outdated building materials. The panels can be installed over existing walls or roofs, providing an immediate upgrade to the building's thermal performance and aesthetic appeal.

Long-Term Value: Durability and Maintenance

Investing in Glass Wool Sandwich Panels is a decision that pays dividends over the long term. The durability of these panels, coupled with their resistance to corrosion and environmental factors, ensures that they maintain their performance and appearance for many years. This longevity translates to reduced maintenance costs and fewer replacements over the life of the building.

Conclusion

Glass Wool Sandwich Panels represent a superior insulation solution for warehouses and factories, offering a unique combination of thermal efficiency, fire safety, and acoustic performance. Their versatility in application, coupled with customizable aesthetics and dimensions, makes them an ideal choice for both new construction and retrofit projects. As industries continue to prioritize energy efficiency, safety, and operational comfort, these innovative panels stand out as a forward-thinking solution that meets the complex demands of modern industrial spaces.

For more information on how Glass Wool Sandwich Panels can benefit your warehouse or factory project, or to explore our range of exterior cladding and facade solutions, please contact us at info@sdqsc.com. Our team of experts at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in creating energy-efficient, safe, and comfortable industrial environments that stand the test of time.

References

1. International Organization for Standardization. (2021). "ISO 10456:2007 Building materials and products — Hygrothermal properties — Tabulated design values and procedures for determining declared and design thermal values."

2. European Committee for Standardization. (2020). "EN 13501-1:2018 Fire classification of construction products and building elements - Part 1: Classification using data from reaction to fire tests."

3. ASTM International. (2019). "ASTM C423-17 Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method."

4. U.S. Department of Energy. (2022). "Insulation Materials." Energy Saver.

5. National Institute of Building Sciences. (2021). "Whole Building Design Guide - Building Envelope Design Guide."