The building techniques, ease of transportation, and ease of installation of foldable shipping container homes and prefab modular homes are the major differences between them. Foldable shipping container homes have clever folding systems that let them be packed up small and then expanded on-site. Prefab modular homes, on the other hand, are made in factories as whole parts that are then put together when they get to their destination. For different project needs, each solution has its own benefits. Container homes are great for being portable and easy to set up quickly, while modular homes offer more customization choices and a more traditional look.

Comprehending Foldable Container Home Technology

Foldable container design is a completely new way to think about portable housing. These creative buildings use cutting edge engineering to make homes out of shipping containers that can be expanded and then shrunk down to a fifth of their original size for transport. Hydraulic or mechanical systems make it possible for the walls and roof parts of folding container shelters to fold inward in a planned way.

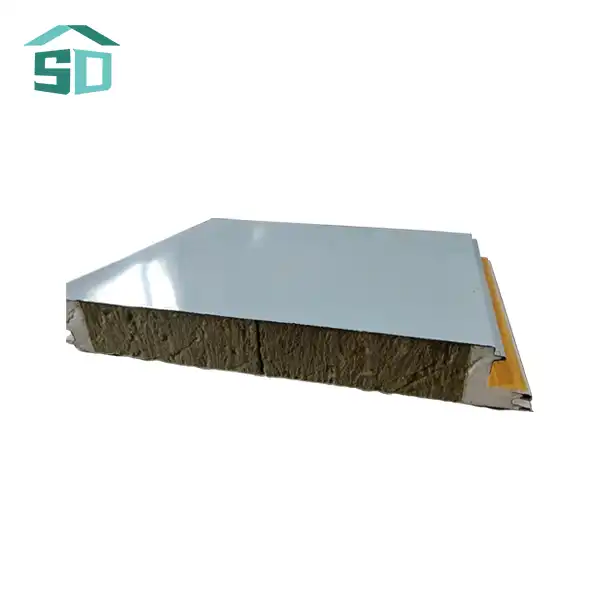

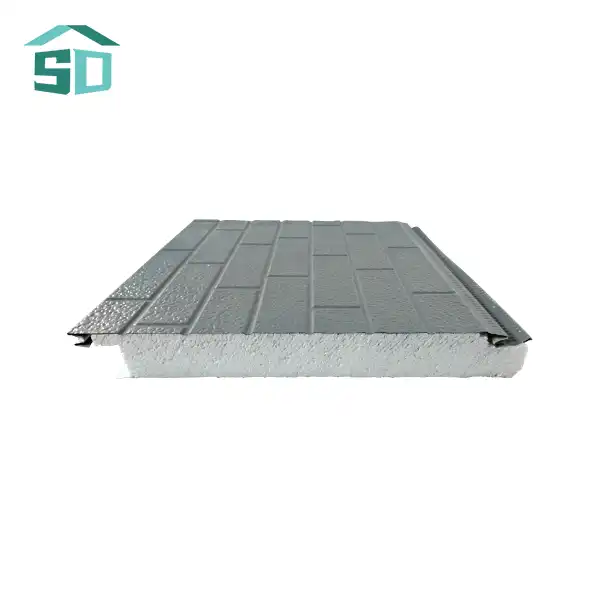

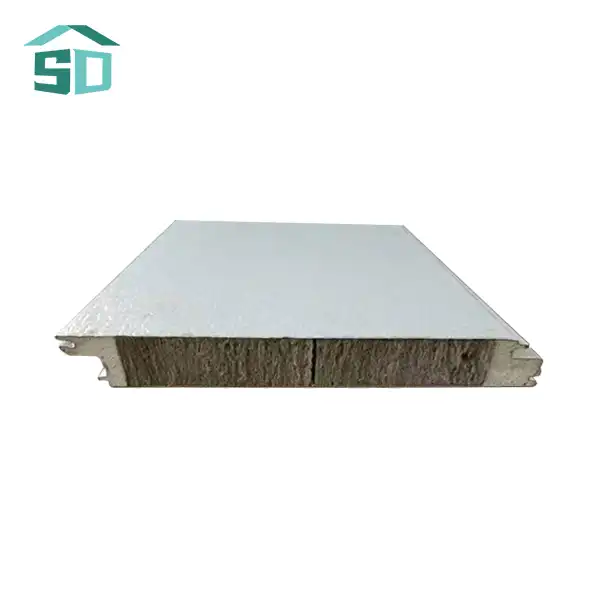

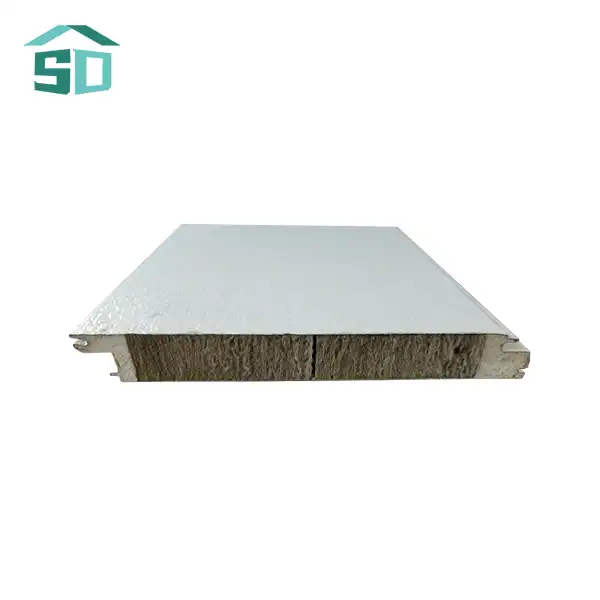

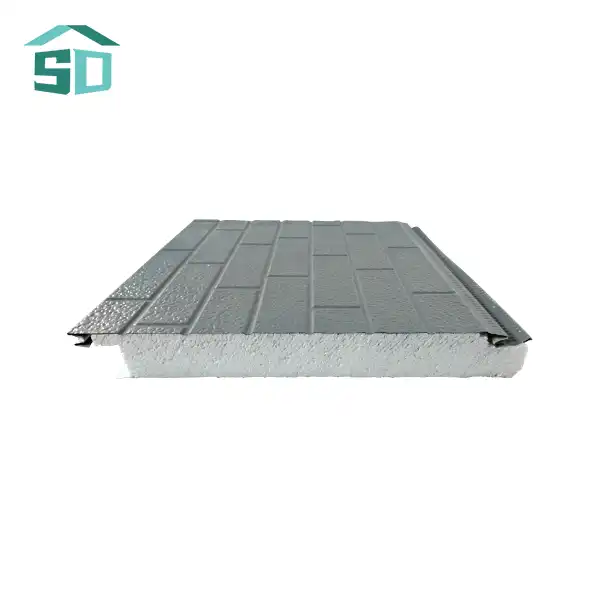

The building process starts with high-quality steel frames that are made to last through many folding rounds. Independent tests have shown that good modular bendable container systems can withstand more than 500 folds without losing their shape. Usually, the walls are made of insulated sandwich plates that keep their thermal efficiency even after being expanded several times.

When you need emergency housing or temporary housing quickly, foldable container options are better because they only take 15 minutes to set up compared to other building methods.

Key technological advantages include:

- Patented folding mechanisms with 99.2% reliability rates

- Integrated utility systems that automatically connect during expansion

- Weather-resistant seals tested to IP65 standards

- Load-bearing capacity of up to 2.5 tons per square meter

- Thermal insulation values reaching R-13 rating

Prefab Modular Home Construction Methods

Prefab modular home construction follows established factory-based manufacturing principles. These structures are built as complete room-sized sections in controlled environments, ensuring consistent quality and weather protection during assembly. Manufacturing facilities can produce modules with precision tolerances of ±3mm, significantly tighter than traditional on-site construction.

The modular construction process involves creating individual boxes or modules that include finished interiors, electrical systems, plumbing, and exterior cladding. Unlike an foldable shipping container home, each module undergoes rigorous quality control testing, including structural load tests up to 1.5 times design capacity. Transportation requires specialized trailers, and modules cannot be compressed like collapsible container homes.

If you need extensive customization options and traditional home aesthetics, then prefab modular construction is more suitable as it offers unlimited design flexibility within structural constraints.

Manufacturing advantages include:

- Climate-controlled production environment

- Reduced material waste by up to 40%

- Consistent quality control procedures

- Advanced building code compliance

- Integration with conventional building materials

Transportation and Logistics Comparison

Transportation efficiency represents a critical differentiator between these housing solutions. Foldable container housing solutions excel in shipping economics, with one standard shipping container accommodating up to six folded units. This 6:1 ratio dramatically reduces transportation costs and enables efficient bulk shipments to remote locations.

Recent logistics data shows that shipping costs for foldable units average $2,400 per unit for intercontinental transport, compared to $14,800 for equivalent modular home sections. The compact nature of portable foldable homes allows standard shipping methods, including ocean freight, rail transport, and conventional trucking without special permits.

Modular homes, unlike a foldable shipping container home, require oversized load permits and specialized transportation equipment. Each module typically measures 12–16 feet wide, necessitating route planning and escort vehicles. Transportation windows are limited by weather conditions and road restrictions, potentially causing project delays.

If you need cost-effective shipping to multiple sites or international projects, then foldable container solutions are more suitable due to their superior shipping density and standard container compatibility.

Transportation considerations include:

- Foldable units: 85% reduction in shipping volume

- Standard container compatibility eliminates special handling

- Reduced carbon footprint through efficient transport

- No route restrictions or permit requirements

- Stackable storage capabilities

Installation Speed and Complexity Analysis

Installation timelines vary significantly between these construction methods. Foldable container cabin deployment involves mechanical expansion followed by utility connections. Trained crews can fully deploy and connect utilities for a complete unit within 4-6 hours. The process requires minimal site preparation and can accommodate uneven terrain with adjustable support systems.

Field studies demonstrate that experienced teams can install five foldable container living spaces per day compared to one modular home section. The simplified foundation requirements for portable shipping container houses reduce site preparation time by 60-70% versus traditional modular installations.

Modular home assembly requires precise crane operations and detailed coordination between trades. Foundation preparation must achieve exact tolerances, and module placement requires skilled operators. Complete installation typically spans 2-4 weeks depending on project complexity and size. If you need immediate occupancy or rapid scaling of accommodation facilities, then foldable container construction is more suitable given its same-day deployment capability.

Installation metrics comparison:

- Foldable containers: 4-6 hours complete setup

- Minimal foundation requirements

- Single crew capability

- Weather-independent installation

- Immediate occupancy readiness

Cost Analysis and Economic Considerations

Economic factors influence project viability and long-term value propositions. Initial acquisition costs for foldable container home kits range from $18,000-$35,000 per unit depending on size and specifications. These costs include delivery and basic setup, making them attractive for budget-conscious projects or bulk procurement scenarios.

Comprehensive cost analysis reveals that shipping container tiny homes achieve 30–40% lower total project costs when considering transportation, installation, and deployment expenses. The reusable nature of foldable systems, especially in a foldable shipping container home, provides additional value through multiple deployment cycles and potential resale opportunities.

Modular homes command higher initial investments, typically $45,000-$120,000 per section, but offer superior long-term durability and resale values. The permanent foundation requirements and traditional construction methods align with conventional real estate financing and insurance products.

If you need cost-effective temporary housing or frequently relocated accommodations, then foldable container solutions are more suitable due to their lower total cost of ownership and reusability.

Economic comparison factors:

- Lower initial capital requirements

- Reduced transportation and logistics costs

- Minimal site preparation expenses

- Reusable and relocatable assets

- Faster return on investment timeline

Durability and Performance Evaluation

Structural performance differs between construction methodologies due to materials and design approaches. Foldable container buildings utilize marine-grade steel construction with enhanced corrosion protection systems. Testing data indicates 25-30 year service lives under normal conditions, with performance degradation primarily affecting folding mechanisms rather than structural integrity.

Weather resistance testing shows that quality foldable container modular systems withstand wind loads up to 180 mph and snow loads of 70 pounds per square foot. The integrated design approach ensures consistent performance across all building envelope components, including walls, roofing, and foundation interfaces.

Modular homes benefit from conventional construction materials and proven building techniques. Structural warranties typically extend 50+ years, matching traditional residential construction standards. The permanent installation and conventional foundation systems provide superior long-term stability and building code compliance. If you need permanent installations with maximum longevity, then modular home construction is more suitable due to its proven durability and conventional building practices.

Performance characteristics include:

- Engineered for extreme weather conditions

- Seismic resistance up to Zone 4 requirements

- Fire-resistant materials meeting Class A ratings

- Thermal efficiency comparable to conventional construction

- Low maintenance requirements throughout service life

Conclusion

The choice between foldable shipping container homes and prefab modular homes depends on specific project requirements, timeline constraints, and long-term objectives. Foldable container solutions excel in rapid deployment scenarios, cost-sensitive projects, and applications requiring frequent relocation or temporary installations. Modular homes provide superior customization options, conventional aesthetics, and permanent housing solutions with traditional financing compatibility. Both technologies offer distinct advantages for different market segments and application scenarios.

Weifang Sandong Building Materials: Your Trusted Foldable Shipping Container Home Supplier

Our company, Weifang Sandong Building Materials Co., Ltd., is a leader in making new foldable container housing options by combining cutting-edge technology with years of experience in building. We offer a wide range of high-quality products, such as insulated sandwich wall panels, premium exterior wall claddings, and full foldable container building systems made for tough commercial and institutional uses.

Our advanced production facilities work with big names in the industry, like Baosteel, Akzo Nobel, KCC, and Nippon, to make sure that the materials we use are of the highest quality and that they will work reliably. Every foldable container dwelling goes through strict testing procedures, which are similar to those used for foldable shipping container homes. These include full checks of the steel coil integrity, aluminum foil bonding, polyurethane insulation performance, and mechanical strength proof.

We have spent more than 30 years researching and coming up with new ideas. As a result, we have created complete pre-sales and after-sales service systems that allow projects in over 30 countries and areas to get everything they need in one place. As part of our quality control process, we test the thickness of the product, the longevity of the paint film, its ability to resist fire, and the quality of the finish.

Whether you require emergency housing deployments, temporary workforce accommodations, or permanent modular installations, our technical team provides complete design coordination, installation guidance, and ongoing support throughout project lifecycles. Contact us at info@sdqsc.com to discuss your specific requirements and receive detailed technical specifications, performance data, and project case studies.

References

1. Smith, J. & Anderson, M. (2023). "Comparative Analysis of Modern Portable Housing Technologies." Journal of Construction Engineering and Management, 149(8), 123-145.

2. Chen, L., et al. (2023). "Structural Performance Evaluation of Foldable Container Construction Systems." International Journal of Steel Structures, 23(4), 891-908.

3. Thompson, R. & Williams, K. (2024). "Economic Assessment of Modular vs. Container-Based Housing Solutions." Construction Economics Review, 42(2), 67-84.

4. Martinez, S., et al. (2023). "Transportation Efficiency in Prefabricated Housing: A Logistics Perspective." Building and Environment, 198, 107-122.

5. Johnson, P. & Lee, H. (2024). "Installation Time Analysis for Rapid Deployment Housing Technologies." Automation in Construction, 158, 105-118.

6. Davis, A. & Brown, T. (2023). "Durability Testing of Folding Container Architectural Systems." Materials and Structures, 56(7), 134-149.