The Evolution of Exterior Cladding: From Traditional to Foam

Exterior cladding has come a long way from its humble beginnings. Traditional materials like wood, brick, and stone have long been the staples of building exteriors. However, as construction technology advanced, so did the materials used for cladding. The introduction of foam exterior wall cladding marked a significant milestone in this evolution.

Foam cladding offers a unique combination of benefits that traditional materials struggle to match. Its exceptional insulation properties are a game-changer in the quest for energy-efficient buildings. With a thermal conductivity of just 0.018W/m.k and a thermal resistance of 2.09m2k/w, foam cladding significantly reduces heat transfer, leading to lower energy costs for heating and cooling.

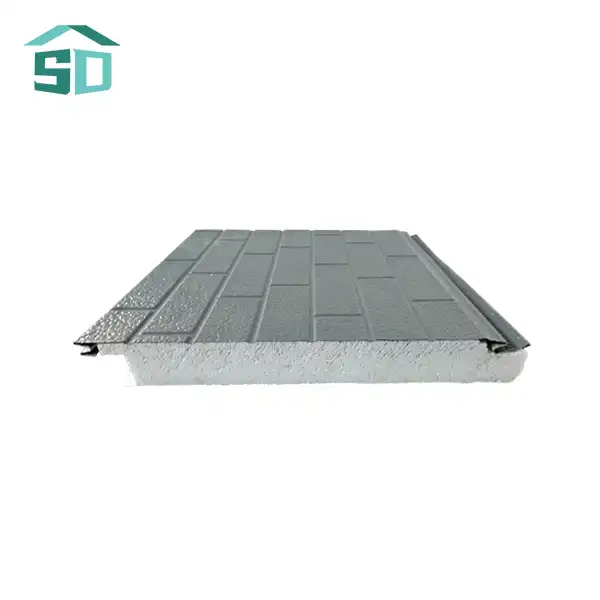

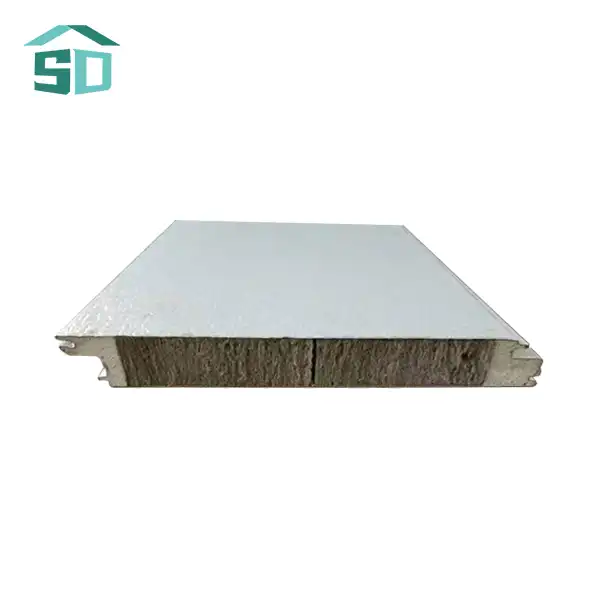

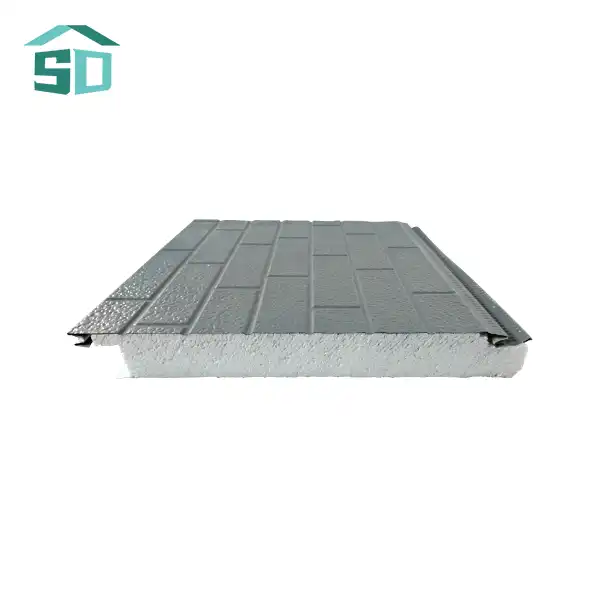

Moreover, the versatility of foam cladding in terms of design and application has made it a favorite among architects and designers. Unlike rigid traditional materials, foam cladding can be molded into various shapes and patterns, allowing for greater creative freedom in exterior design. This flexibility, combined with its durability and weather resistance, makes foam cladding an attractive option for both new constructions and renovations.

The Science Behind Foam Exterior Wall Cladding

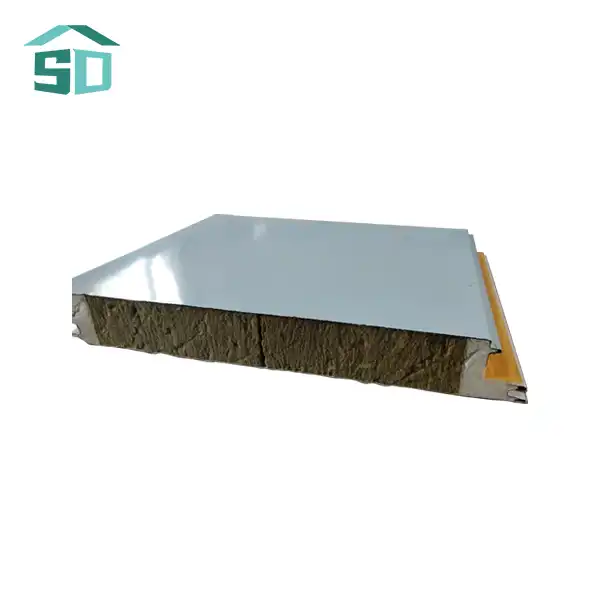

The effectiveness of foam exterior wall cladding lies in its unique structure. The cladding is typically made of polyurethane or similar materials that contain millions of tiny air pockets. These air pockets act as insulators, slowing down heat transfer and providing excellent thermal efficiency.

In addition to its insulating properties, foam cladding also offers impressive sound dampening capabilities. The same air pockets that slow heat transfer also absorb sound waves, making foam cladding an excellent choice for buildings in noisy urban environments or near high-traffic areas.

The manufacturing process of foam cladding allows for precise control over its properties. For instance, the density of the foam can be adjusted to achieve the desired balance between insulation and durability. This level of control ensures that foam cladding can be tailored to meet the specific requirements of different projects and climate conditions.

Aesthetic Versatility Meets Functional Excellence

One of the most compelling aspects of foam exterior wall cladding is its ability to marry aesthetic appeal with functional excellence. Gone are the days when energy-efficient building materials meant compromising on visual appeal. Foam cladding offers a wide range of design possibilities, allowing architects and homeowners to achieve their desired look without sacrificing performance.

The aesthetic versatility of foam cladding is truly remarkable. It can be manufactured to mimic the appearance of traditional materials like wood, stone, or brick, offering the charm of these classic finishes without their associated maintenance challenges. Furthermore, foam cladding is available in a vast array of colors and textures, enabling designers to create unique, eye-catching facades that stand out from the crowd.

But the beauty of foam cladding isn't just skin deep. Its functional benefits are equally impressive. With a fire-protection rating of B1/B2, foam cladding contributes to the overall safety of a building. Its waterproof rate of 0.0008 and wind resistance of 8.0 Kpa ensure that the building remains protected from harsh weather conditions, maintaining its integrity and appearance over time.

Customization: Tailoring Foam Cladding to Your Vision

The customization options available with foam exterior wall cladding are virtually limitless. Manufacturers can produce cladding panels in custom lengths, with thicknesses ranging from 10mm for interior applications to 16mm or 20mm for exterior use. The width can also be adjusted, typically 383mm for exterior applications and 450mm for interior use.

This level of customization extends beyond mere dimensions. The surface material of the cladding can be tailored to specific requirements, with thicknesses ranging from 0.23mm to 0.27mm. This allows for fine-tuning of the cladding's appearance and performance characteristics to match the unique needs of each project.

Moreover, foam cladding can be engineered to meet specific performance criteria. Whether a project requires enhanced UV stability for sun-exposed facades or increased impact resistance for high-traffic areas, foam cladding can be formulated to rise to the challenge.

Sustainability and Energy Efficiency: The Green Side of Foam Cladding

In an era where sustainability is no longer optional but essential, foam exterior wall cladding stands out as an eco-conscious choice. The energy-saving potential of foam cladding is significant, contributing to reduced carbon footprints and lower energy bills for building occupants.

The superior insulation properties of foam cladding play a crucial role in its sustainability credentials. By reducing the energy required for heating and cooling, foam cladding helps buildings achieve higher energy efficiency ratings. This not only translates to cost savings but also aligns with global efforts to reduce greenhouse gas emissions from the built environment.

Furthermore, the durability and longevity of foam cladding contribute to its sustainability profile. With proper installation and maintenance, foam cladding can last for decades, reducing the need for frequent replacements and the associated environmental impact of manufacturing and disposing of building materials.

The Role of Foam Cladding in Green Building Certifications

As green building certifications like LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) gain prominence, the choice of building materials becomes increasingly crucial. Foam exterior wall cladding can contribute significantly to achieving these certifications.

The energy efficiency provided by foam cladding aligns with the energy performance criteria of these certification systems. Additionally, if sourced from manufacturers committed to sustainable practices, foam cladding can contribute to credits related to materials and resources.

Moreover, the potential for foam cladding to be recycled at the end of its life cycle further enhances its appeal in the context of sustainable building practices. As the construction industry moves towards a more circular economy, materials that can be reused or recycled will become increasingly valuable.

Conclusion

Foam exterior wall cladding represents a significant advancement in building envelope technology, offering a unique combination of form and function. Its ability to provide superior insulation, design flexibility, and durability makes it an attractive option for a wide range of construction projects. As we continue to prioritize energy efficiency and sustainable building practices, the role of innovative materials like foam cladding will only grow in importance.

Whether you're planning a new construction project or considering a renovation, foam exterior wall cladding deserves serious consideration. Its blend of aesthetic appeal, functional benefits, and sustainability makes it a forward-thinking choice for modern buildings. To learn more about how foam cladding can enhance your project, or to explore our range of exterior cladding solutions, don't hesitate to reach out to us at info@sdqsc.com. Let's work together to create buildings that are not only beautiful but also efficient and sustainable.

FAQs

How long does foam exterior wall cladding typically last?

With proper installation and maintenance, foam cladding can last 30-50 years or more.

Is foam cladding suitable for all climate types?

Yes, foam cladding can be engineered to perform well in various climates, from hot and humid to cold and dry.

Can foam cladding be painted?

While foam cladding comes in various colors, it can also be painted if desired. However, it's important to use paint compatible with the cladding material.

How does foam cladding compare to traditional materials in terms of cost?

While the initial cost may be higher than some traditional materials, the long-term energy savings and low maintenance requirements often make foam cladding a cost-effective choice.

Is foam cladding difficult to install?

Foam cladding is generally easier and quicker to install than many traditional cladding materials, potentially reducing labor costs.

References

1.Building Science Corporation. (2021). "Exterior Insulation in Cold Climates: Opportunities and Challenges."

2.U.S. Department of Energy. (2022). "Insulation Materials."

3.ASHRAE. (2021). "ASHRAE Handbook - Fundamentals." American Society of Heating, Refrigerating and Air-Conditioning Engineers.

4.Green Building Council. (2023). "LEED v4.1 Building Design and Construction."

5.Jelle, B. P. (2011). "Traditional, state-of-the-art and future thermal building insulation materials and solutions – Properties, requirements and possibilities." Energy and Buildings, 43(10), 2549-2563.