Introducing Fireproof Insulation Panel Ratings and Standards

Fireproof insulation panels play a crucial role in enhancing building safety and energy efficiency. These innovative materials combine robust fire resistance with excellent thermal insulation properties, making them an ideal choice for various construction projects. To fully appreciate their benefits and ensure proper implementation, it's essential to understand the ratings and standards associated with these panels.

Fire Resistance Ratings Explained

Fire resistance ratings are a fundamental aspect of fireproof insulation panels. These ratings indicate how long a panel can withstand exposure to fire without compromising its structural integrity. The most common rating system used globally is the one established by the European Standard EN 13501-1. This system classifies materials into categories ranging from A1 (non-combustible) to F (easily flammable).

For instance, panels with an A1 or A2 rating offer the highest level of fire resistance. These panels are typically made from materials like mineral wool or fiberglass, which are inherently non-combustible. B1 and B2 rated panels, while still fire-resistant, may contain some combustible components but are designed to limit fire spread effectively.

Thermal Insulation Standards

While fire resistance is paramount, the insulation properties of these panels are equally important. Thermal insulation is measured by the R-value, which indicates the panel's resistance to heat flow. Higher R-values signify better insulation performance. Building codes often specify minimum R-values for different climate zones and building types to ensure energy efficiency.

Modern fireproof insulation panels often boast impressive R-values, thanks to advanced materials like polyurethane and polystyrene. These materials provide excellent thermal insulation without compromising fire safety when properly engineered and installed.

Certification and Testing Protocols

To ensure compliance with building codes, fireproof insulation panels undergo rigorous testing and certification processes. These tests simulate real-world fire scenarios and assess the panel's performance under extreme conditions. Common certifications include ISO, CE, and UL listings, which are internationally recognized marks of quality and safety.

Manufacturers of high-quality fireproof insulation panels, like Weifang Sandong Building Materials Co., Ltd., invest heavily in research and development to create products that not only meet but often exceed these stringent standards. Their panels undergo comprehensive inspections, including tests for thickness, mechanical strength, and flame retardancy, ensuring top-notch performance and reliability.

Implementing Fireproof Insulation Panels in Construction Projects

Implementing fireproof insulation panels in construction projects requires careful planning and execution. These panels offer a myriad of benefits, from enhanced fire safety to improved energy efficiency, but their proper installation is crucial to maximize their effectiveness and ensure compliance with building codes.

Design Considerations and Material Selection

The first step in implementing fireproof insulation panels is selecting the right materials for the specific project requirements. Factors to consider include the building's purpose, local climate conditions, and specific fire safety regulations. For instance, a industrial warehouse might require panels with higher fire resistance ratings compared to a residential complex.

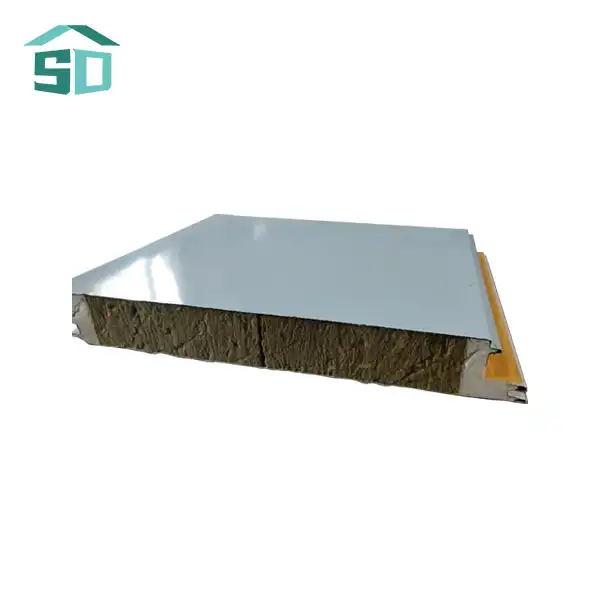

Architects and builders should also consider the panel's composition. Options range from metal-faced panels with non-combustible mineral wool cores to innovative eco-friendly solutions made from recycled materials. The choice depends on factors like budget, aesthetic preferences, and environmental considerations.

Installation Best Practices

Proper installation is paramount to the performance of fireproof insulation panels. This process typically involves several key steps:

- Surface Preparation: Ensuring the underlying structure is clean, dry, and structurally sound.

- Panel Cutting: Using appropriate tools to cut panels to size, if necessary, without compromising their fire-resistant properties.

- Secure Attachment: Utilizing suitable fasteners and following manufacturer guidelines for spacing and placement.

- Sealing: Applying fire-resistant sealants to joints and edges to maintain the integrity of the fire barrier.

- Quality Control: Conducting thorough inspections to identify and address any gaps or inconsistencies in the installation.

It's crucial to work with experienced installers who are familiar with the specific requirements of fireproof insulation panels. Many manufacturers, including Weifang Sandong Building Materials Co., Ltd., provide detailed installation guides and may offer training or support to ensure proper implementation.

Integration with Building Systems

Fireproof insulation panels must be seamlessly integrated with other building systems to maximize their effectiveness. This includes coordinating with electrical, plumbing, and HVAC installations to ensure that any penetrations through the panels are properly sealed and do not compromise fire resistance.

Additionally, these panels can be part of a broader fire safety strategy, working in conjunction with other elements like fire doors, sprinkler systems, and smoke detectors. When properly integrated, fireproof insulation panels contribute significantly to the overall fire safety and energy efficiency of a building.

Maintaining Compliance and Long-Term Performance

Ensuring ongoing compliance and maintaining the long-term performance of fireproof insulation panels is crucial for building safety and efficiency. This process involves regular inspections, timely maintenance, and staying abreast of evolving building codes and standards.

Regular Inspection and Maintenance

Periodic inspections are essential to verify the continued effectiveness of fireproof insulation panels. These inspections should check for any signs of damage, such as cracks, gaps, or deterioration that could compromise fire resistance or insulation properties. Key areas to focus on include:

- Panel Joints: Ensuring seals remain intact and free from gaps.

- Surface Integrity: Checking for any scratches, dents, or other damage to the panel surface.

- Fastener Security: Verifying that all fasteners remain tight and corrosion-free.

- Moisture Intrusion: Looking for any signs of water damage or mold growth.

Maintenance activities might include reapplying sealants, replacing damaged panels, or addressing any issues that could affect performance. It's advisable to keep detailed records of all inspections and maintenance activities for compliance purposes and to track the panels' performance over time.

Adapting to Code Changes

Building codes and fire safety standards are continually evolving as new technologies and research emerge. Staying informed about these changes is crucial for maintaining compliance. This might involve:

- Regular consultations with local building authorities.

- Attending industry seminars or workshops on fire safety and building materials.

- Subscribing to relevant professional publications or newsletters.

In some cases, code changes may necessitate upgrades or modifications to existing fireproof insulation panel installations. Building owners and managers should be prepared to make these adjustments to ensure ongoing compliance and optimal fire safety.

Performance Monitoring and Documentation

Implementing a system for ongoing performance monitoring can provide valuable insights into the effectiveness of fireproof insulation panels over time. This might include:

- Thermal imaging to detect any changes in insulation performance.

- Air tightness testing to ensure the building envelope remains sealed.

- Energy consumption analysis to verify continued energy efficiency.

Maintaining comprehensive documentation of the panels' specifications, installation details, and performance data is essential. This information can be invaluable for future renovations, insurance purposes, or demonstrating compliance during building inspections.

Conclusion

Fireproof insulation panels represent a significant advancement in building safety and energy efficiency. By understanding the ratings, implementing proper installation techniques, and maintaining long-term compliance, builders and property owners can create safer, more sustainable structures. These panels not only meet stringent building code requirements but also contribute to the overall resilience and performance of buildings in various sectors.

As the construction industry continues to evolve, the importance of fire safety and energy efficiency will only grow. Fireproof insulation panels are at the forefront of this evolution, offering a solution that balances safety, performance, and sustainability. By choosing high-quality panels and working with experienced providers, builders can ensure their projects meet current standards and are prepared for future challenges.

For more information on cutting-edge fireproof insulation panels and how they can enhance your construction projects, contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to assist you in selecting the right solutions for your specific needs, ensuring your building not only meets but exceeds safety and efficiency standards.

FAQ

What materials are commonly used in fireproof insulation panels?

Common materials include mineral wool, fiberglass, polyurethane, and polystyrene, often combined with metal facings like aluminum or steel.

How long do fireproof insulation panels typically last?

With proper installation and maintenance, these panels can last 30 years or more, depending on environmental conditions and usage.

Can fireproof insulation panels be used in both residential and commercial buildings?

Yes, these panels are versatile and can be used in various building types, from homes to industrial facilities, adapting to different fire safety requirements.

How do I know if my building's fireproof insulation panels are still compliant with current codes?

Regular inspections by certified professionals and staying informed about local building code updates are key to ensuring ongoing compliance.

References

1.European Standard EN 13501-1: Fire classification of construction products and building elements.

2.International Building Code (IBC): Fire-resistance-rated construction requirements.

3.National Fire Protection Association (NFPA) Standards: Guidelines for fire safety in buildings.

4.U.S. Department of Energy: Energy efficiency standards and R-value recommendations.

5.ISO 9001:2015: Quality management systems - Requirements.