The Anatomy of Fire Rated Sandwich Panel Walls

Core Components and Construction

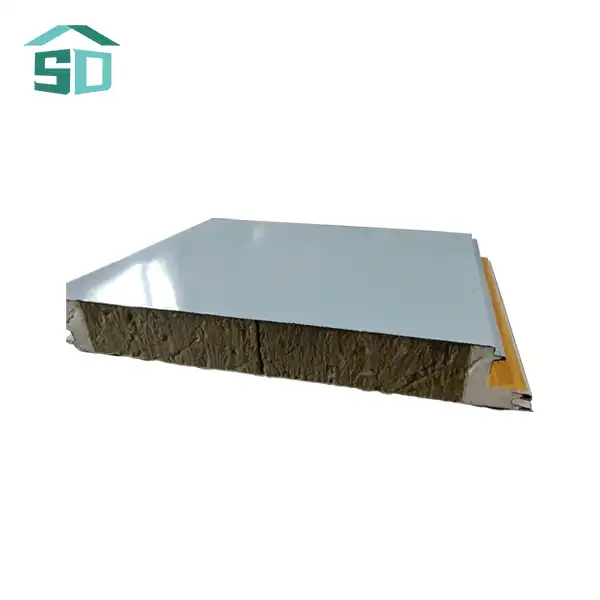

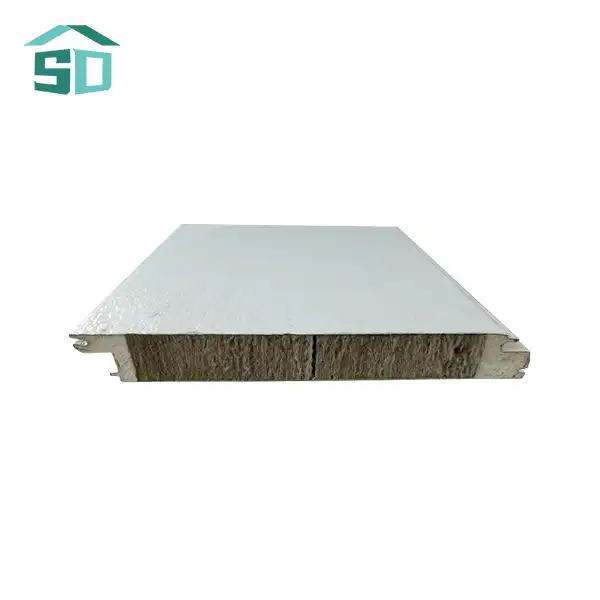

Fire rated sandwich panel walls are engineered marvels, consisting of three primary layers that work in harmony to provide exceptional performance. The outer layers, typically made of durable materials like aluminum, galvanized steel, or stainless steel, form a robust exterior that can withstand harsh weather conditions and resist corrosion. These exterior layers not only provide structural strength but also offer a wide range of aesthetic options, available in various RAL colors and with PVDF coating for enhanced durability and visual appeal.

At the heart of these panels lies the insulation core, which plays a crucial role in both fire resistance and thermal efficiency. Depending on the specific requirements, the core can be composed of different materials:

- Polyurethane (PU): Known for its excellent thermal insulation properties, with a thermal conductivity of 0.022 W/mK.

- Polystyrene (EPS): Offers good insulation with a thermal conductivity of 0.037 W/mK.

- Rockwool: Provides superior fire resistance, achieving up to an A1 fire rating.

The sandwich construction technique ensures that these layers are bonded securely, creating a unified panel that combines the strengths of each component. This innovative design allows for panels of varying thicknesses, typically ranging from 50mm to 150mm, to cater to different insulation and structural needs.

Fire Resistance Mechanism

The fire resistance of sandwich panel walls is not just a feature; it's a carefully engineered property that can save lives and protect property. The key to their fire-resistant nature lies in the combination of materials used and the panel's overall design. When exposed to fire, the exterior layers act as a initial barrier, slowing the spread of flames. Meanwhile, the insulation core, especially when made of non-combustible materials like rockwool, provides an additional layer of protection.

These panels undergo rigorous testing to ensure they meet stringent fire safety standards. The fire rating of up to A1 for rockwool-insulated panels is a testament to their ability to withstand high temperatures and prevent fire spread. This level of fire resistance is crucial in commercial and industrial settings where safety is paramount.

Benefits Beyond Fire Safety

Energy Efficiency and Thermal Performance

While fire safety is a critical aspect of sandwich panel walls, their benefits extend far beyond fire resistance. One of the most significant advantages is their exceptional thermal performance. The insulation core, whether it's polyurethane, polystyrene, or rockwool, creates a formidable thermal barrier that significantly reduces heat transfer between the interior and exterior of a building.

This thermal efficiency translates into tangible benefits for building owners and occupants:

- Reduced energy consumption for heating and cooling

- Lower utility costs

- Improved indoor comfort

- Contribution to green building initiatives

The thermal conductivity values of 0.022 W/mK for PU and 0.037 W/mK for EPS insulation are indicative of their superior insulating properties. This level of insulation helps maintain consistent indoor temperatures, reducing the load on HVAC systems and contributing to overall energy efficiency.

Versatility and Customization

Sandwich panel walls offer unparalleled versatility in design and application. Available in standard widths of 1000mm and 1200mm, with customizable lengths to fit specific project requirements, these panels can be adapted to a wide range of architectural styles and building types. From sleek, modern office buildings to industrial warehouses and residential complexes, sandwich panels provide a flexible solution that meets diverse needs.

The customization options extend to the aesthetic realm as well. With a variety of colors and surface treatments available, architects and designers can create visually striking facades that enhance the overall appearance of a building. The PVDF coating option adds an extra layer of durability and weather resistance, ensuring that the panels maintain their appearance over time.

Applications and Industry Impact

Wide-Ranging Uses in Construction

The versatility of fire rated sandwich panel walls has led to their adoption across various sectors of the construction industry. Their applications include:

- Commercial buildings: Offices, retail spaces, and warehouses

- Industrial facilities: Manufacturing plants and storage units

- Residential projects: Multi-family housing and custom homes

- Institutional buildings: Schools, hospitals, and government facilities

- Cold storage and controlled environment structures

The ability to use these panels for both interior and exterior wall designs adds to their appeal, allowing for consistent performance and aesthetics throughout a building. Their lightweight nature also makes them an excellent choice for renovation projects, where minimal structural load is crucial.

Regulatory Compliance and Industry Standards

The construction industry is heavily regulated, particularly when it comes to safety and performance standards. Fire rated sandwich panel walls have gained widespread acceptance due to their ability to meet and exceed these stringent requirements. Certifications such as ISO, CE, UL, and FM Approval underscore the quality and reliability of these panels.

These certifications not only provide peace of mind to builders and property owners but also streamline the approval process for construction projects. By choosing certified sandwich panel walls, developers can ensure compliance with local building codes and international standards, potentially expediting project timelines and reducing regulatory hurdles.

Environmental Considerations

As the construction industry moves towards more sustainable practices, the eco-friendly aspects of sandwich panel walls become increasingly important. The energy efficiency of these panels contributes to reduced carbon footprints for buildings over their lifecycle. Additionally, the durability and longevity of sandwich panels mean less frequent replacements and renovations, further reducing environmental impact.

Many manufacturers are also focusing on using recyclable materials and implementing environmentally friendly production processes, aligning with the growing demand for green building materials. This commitment to sustainability not only benefits the environment but also appeals to eco-conscious clients and can contribute to green building certifications.

Conclusion

Fire rated sandwich panel walls represent a significant advancement in building technology, offering a perfect blend of safety, efficiency, and versatility. Their ability to provide superior fire resistance while delivering excellent thermal performance makes them an invaluable asset in modern construction. From their customizable aesthetics to their wide-ranging applications, these panels are reshaping the way we approach building design and safety.

As the construction industry continues to evolve, the demand for innovative, high-performance materials like sandwich panel walls is likely to grow. Their capacity to meet stringent safety standards while contributing to energy efficiency and sustainability goals positions them as a key component in the future of building design and construction.

For those looking to explore the benefits of fire rated sandwich panel walls for their next project, or to learn more about exterior cladding and facade solutions, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and top-quality products. Contact us at info@sdqsc.com to discover how our innovative solutions can enhance your construction projects.