The Environmental Benefits of Vertical Metal Siding Panels

Recyclable Materials: A Circular Economy Approach

Vertical metal siding boards are essentially built from recyclable materials such as aluminum, steel, and copper. This characteristic places them at the cutting edge of economical building materials. The recyclability of these boards essentially decreases the request for crude materials, in this way moderating normal assets and minimizing natural effects. At the conclusion of their lifecycle, which can span a few decades, these boards can be completely reused, contributing to a circular economy shown in the development industry.

Energy Efficiency: Reducing Carbon Footprints

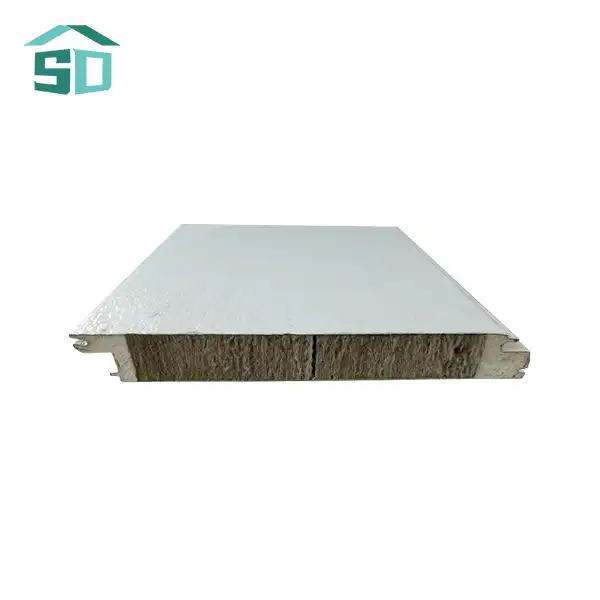

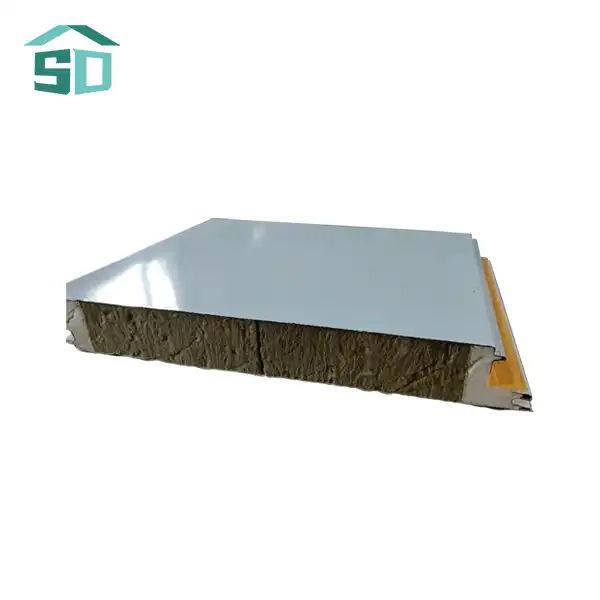

One of the most compelling eco-friendly aspects of vertical metal siding panels is their superior energy efficiency. These panels, when coupled with high-performance insulation materials like polyurethane, polystyrene, rock wool, or glass wool, create an effective thermal barrier. This insulation prowess helps maintain stable indoor temperatures, reducing the reliance on heating and cooling systems. Consequently, buildings clad with these panels experience lower energy consumption, leading to reduced greenhouse gas emissions and smaller carbon footprints.

Longevity: Minimizing Waste and Resource Consumption

The durability of vertical metal siding panels is a key factor in their sustainability profile. These panels are engineered to withstand harsh weather conditions, resist corrosion, and maintain their integrity for decades. The longevity of these panels translates to less frequent replacements, thereby reducing waste generation and the need for new materials over time. This durability not only conserves resources but also minimizes the environmental impact associated with the manufacturing and transportation of replacement materials.

Sustainable Manufacturing Practices in Vertical Metal Siding Production

Advanced Production Lines: Efficiency and Quality Control

The fabricating handle of vertical metal siding boards has advanced to join economical homes. State-of-the-art generation lines are outlined to maximize productivity while minimizing waste. Thorough quality control frameworks guarantee that each board meets exacting measures for thickness, paint film strength, mechanical quality, and fire retardancy. This fastidious consideration to quality not only improves the panels' execution but also diminishes the probability of surrenders and untimely substitutions, further contributing to maintainability.

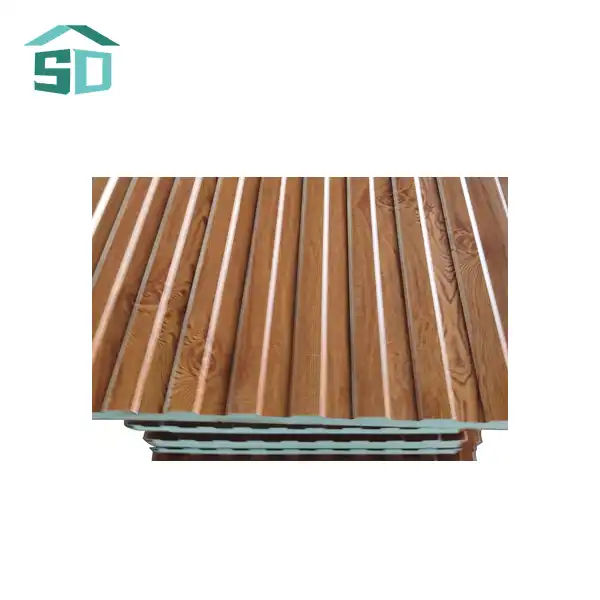

Eco-Friendly Coatings and Finishes

The surface treatment of vertical metal siding panels plays a crucial role in their environmental impact. Modern coating and painting processes utilize eco-friendly materials that are low in volatile organic compounds (VOCs). These environmentally conscious finishes not only provide essential protection against UV radiation and corrosion but also ensure that the panels do not release harmful substances into the environment over time. Additionally, anodizing processes for aluminum panels have been refined to minimize chemical usage and energy consumption.

Waste Reduction and Resource Optimization

Sustainable manufacturing of vertical metal siding panels emphasizes waste reduction and resource optimization. Manufacturers are increasingly adopting lean production techniques to minimize material waste during the cutting and shaping processes. Scrap metal is meticulously collected and recycled, often being reintegrated into the production cycle. Water used in the manufacturing process is treated and reused, significantly reducing the overall water footprint of panel production.

Versatility and Adaptability: Expanding the Scope of Sustainable Construction

Wide Range of Applications

The versatility of vertical metal siding panels amplifies their sustainability impact across various construction sectors. These panels find application in a diverse array of projects, including residential complexes, office buildings, villas, gardens, historic building renovations, municipal structures, and even security kiosks. This adaptability means that sustainable building practices can be implemented across a broad spectrum of architectural styles and functional requirements, expanding the reach of eco-friendly construction solutions.

Customization for Maximum Efficiency

The ability to customize vertical metal siding panels further enhances their sustainability credentials. Panels can be tailored to specific project requirements, with options for size (e.g., 12" x 96", 24" x 120"), thickness (24, 26, 28 gauge), and color (including custom colors beyond standard options like White, Black, Gray, and Blue). This customization ensures optimal material usage, reducing waste and improving overall building efficiency. Moreover, the ability to match panels to specific architectural designs promotes the longevity of buildings by ensuring they remain aesthetically pleasing and functionally relevant for extended periods.

Integration with Other Sustainable Technologies

Vertical metal siding panels can be seamlessly integrated with other sustainable building technologies. For instance, their durability and structural integrity make them ideal for supporting solar panel installations, facilitating the adoption of renewable energy sources in buildings. Additionally, their reflective properties can be harnessed to create cool roofs and walls, further enhancing a building's energy efficiency. This synergy between vertical metal siding panels and other green technologies creates a comprehensive approach to sustainable construction.

Conclusion

Vertical metal siding panels represent a significant stride towards more sustainable and eco-friendly construction practices. Their recyclability, energy efficiency, and durability make them an exemplary choice for environmentally conscious builders and homeowners. As the construction industry continues to evolve towards more sustainable practices, these panels stand out as a versatile, adaptable, and eco-friendly solution that meets both aesthetic and functional requirements while minimizing environmental impact.

By choosing vertical metal siding panels, we're not just building structures; we're investing in a more sustainable future for our planet. For more information on how vertical metal siding panels can contribute to your sustainable construction project, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in making eco-friendly choices that align with your building goals and environmental values.