The Resilience of Wood Grain Metal Siding: A Closer Look

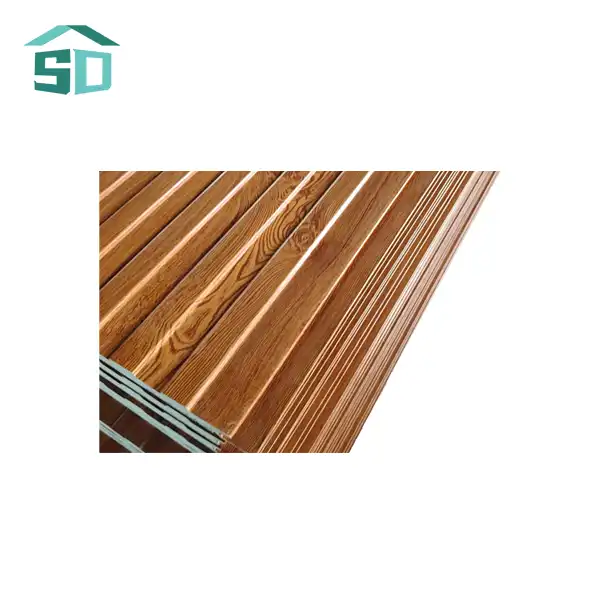

Wood grain metal siding represents a significant leap forward in exterior cladding technology. This innovative product combines the aesthetic appeal of wood with the durability and low maintenance of metal, offering homeowners and builders the best of both worlds.

One of the primary advantages of wood grain metal siding is its remarkable resistance to denting. Unlike traditional wood siding, which can easily dent or chip, wood grain metal siding is engineered to withstand various environmental challenges. The metal base, typically aluminum or steel, provides a robust foundation that can absorb impact without significant damage.

The thickness of the metal plays a crucial role in its dent resistance. Wood grain metal siding is available in various thicknesses, commonly ranging from 1.0 mm to 2.0 mm. This substantial thickness contributes to its ability to resist denting from everyday impacts, such as hail or accidental bumps.

Enhanced Durability Through Advanced Manufacturing

The durability of wood grain metal siding is largely achieved through advanced surface treatments applied during the production process. These treatments typically involve protective coatings, precision painting, and anodizing, which replicate the natural wood grain texture while improving resistance to environmental factors. Beyond enhancing visual appeal, these finishes create a durable shield against moisture, UV rays, and corrosion. As a result, the siding maintains its aesthetic and structural integrity for extended periods, even when exposed to harsh outdoor conditions.

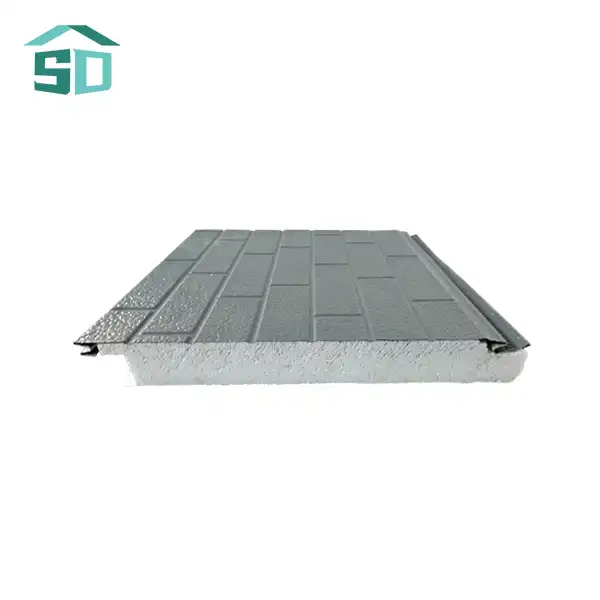

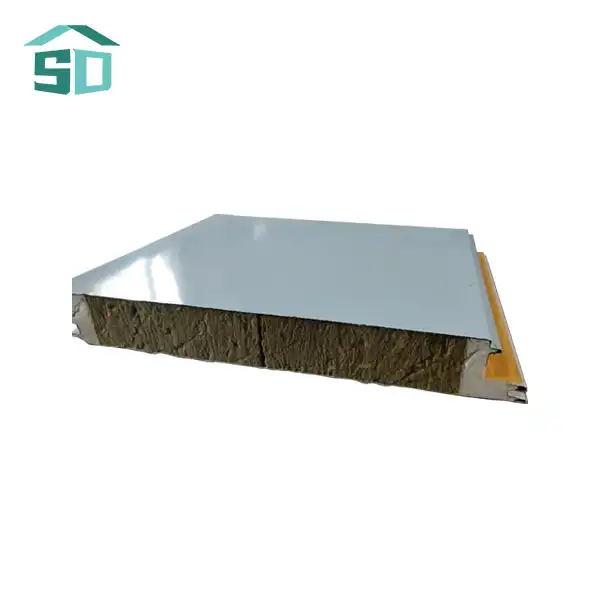

In addition to weather resistance, these surface treatments greatly improve the siding’s ability to endure physical impacts without denting. The durable, multi-layered coatings form a resilient surface that helps absorb minor impacts from debris or accidental contact. Complementing this, the siding’s layered structure often includes insulation materials like polyurethane or polystyrene. These insulation layers act as added cushioning, distributing force and reducing the risk of dents. This combined system ensures lasting protection and durability for both residential and commercial buildings.

Comparing Wood Grain Metal Siding to Other Materials

When evaluating the dent resistance of wood grain metal siding, it's helpful to compare it to other common siding materials. Traditional wood siding, while beautiful, is susceptible to dents, chips, and cracks. Vinyl siding, another popular option, can crack or warp under impact or extreme temperatures.

In contrast, wood grain metal siding offers superior resistance to these issues. Its metal core provides a level of durability that surpasses many alternative materials. This resilience translates to long-term cost savings, as the need for repairs and replacements is significantly reduced.

Performance in Extreme Conditions

Wood grain metal siding truly shines in its ability to withstand extreme weather conditions. In areas prone to hailstorms, for instance, this type of siding demonstrates remarkable resilience. While a severe hailstorm might leave traditional siding materials battered and in need of replacement, wood grain metal siding is likely to emerge unscathed or with minimal damage.

Moreover, the corrosion-resistant properties of wood grain metal siding make it an excellent choice for coastal areas or regions with high humidity. The siding's ability to resist rust and degradation ensures its appearance and structural integrity remain intact for years, even in challenging environments.

Maintenance and Longevity of Wood Grain Metal Siding

One of the most appealing aspects of wood grain metal siding is its low maintenance requirements. Unlike wood siding, which needs regular painting or staining, wood grain metal siding retains its appearance with minimal upkeep. This characteristic not only saves time and money but also contributes to the siding's longevity.

The durability of wood grain metal siding extends beyond its resistance to dents. Its non-flammable nature, meeting ASTM E84 standards, enhances the safety of both residential and commercial spaces. This fire-resistant quality can be a crucial factor in areas prone to wildfires or for buildings that require heightened safety measures.

Eco-Friendly Aspects of Wood Grain Metal Siding

In an era where sustainability is increasingly important, wood grain metal siding stands out as an eco-conscious choice. As a sustainable alternative to traditional wood siding, it helps conserve forest resources. Additionally, metal siding is often made from recycled materials and is itself recyclable at the end of its lifecycle, contributing to a more circular economy in the construction industry.

The energy efficiency of wood grain metal siding is another aspect worth noting. The insulation layer, typically made of polyurethane or polystyrene, provides excellent thermal insulation. This feature contributes to reduced energy consumption for heating and cooling, leading to lower energy bills and a smaller carbon footprint for the building.

Conclusion

Wood grain metal siding represents a pinnacle in siding technology, offering exceptional dent resistance along with numerous other benefits. Its durability, low maintenance requirements, and aesthetic versatility make it an excellent choice for a wide range of architectural styles and building types.

While no siding material is entirely impervious to damage, wood grain metal siding's resistance to denting, coupled with its other advantageous properties, positions it as a superior option in the exterior cladding market. For those seeking a siding solution that combines durability, beauty, and long-term value, wood grain metal siding is certainly worth considering.

If you're interested in learning more about wood grain metal siding or other exterior cladding solutions, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect siding solution for your project.