The Science Behind Rust-Resistant Corrugated Steel Siding Panels

Corrugated steel siding panels are a marvel of modern engineering, combining strength, style, and durability. Their rust-resistant properties are not just a happy accident but the result of careful design and material selection. Let's delve into the science that makes these panels so resilient against the elements.

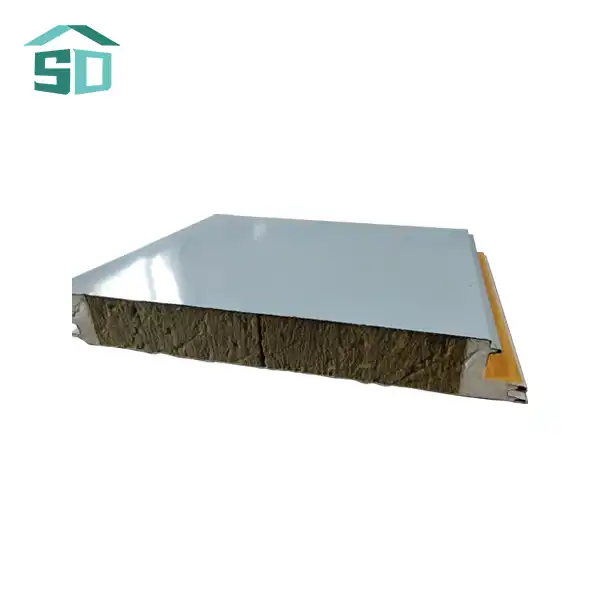

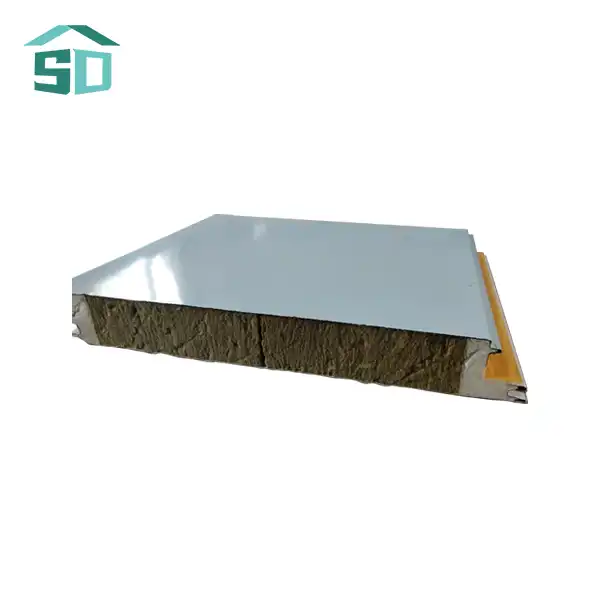

Galvanization: The First Line of Defense

The essential reason folded steel boards stand up to rust so viably is the galvanization prepare. Amid this handle, the steel is coated with a layer of zinc. This zinc coating serves two vital functions:

- Barrier Assurance: The zinc acts as a physical obstruction between the steel and the environment, anticipating water and oxygen from specifically reaching the steel surface.

- Sacrificial Assurance: Indeed if the zinc coating is scratched or harmed, it proceeds to secure the steel through a prepare called cathodic security. The zinc will erode specially, relinquishing itself to ensure the basic steel.

The thickness of this galvanized coating can change, with choices ordinarily accessible in 24, 26, and 28 gage. The thicker the gage, the more vigorous the assurance against rust and erosion.

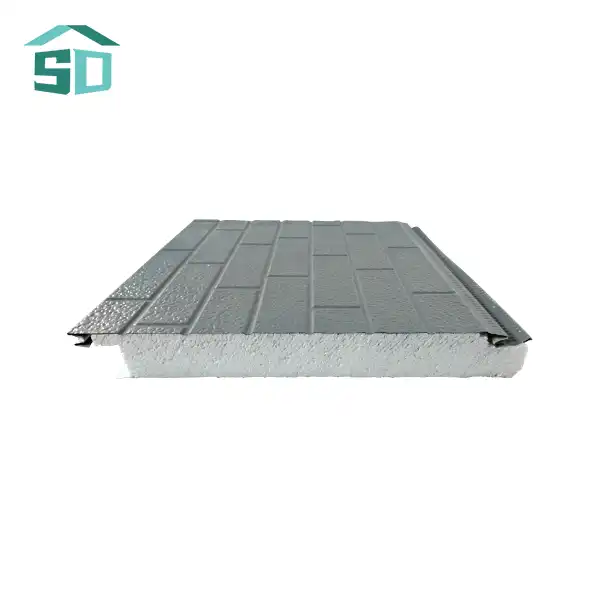

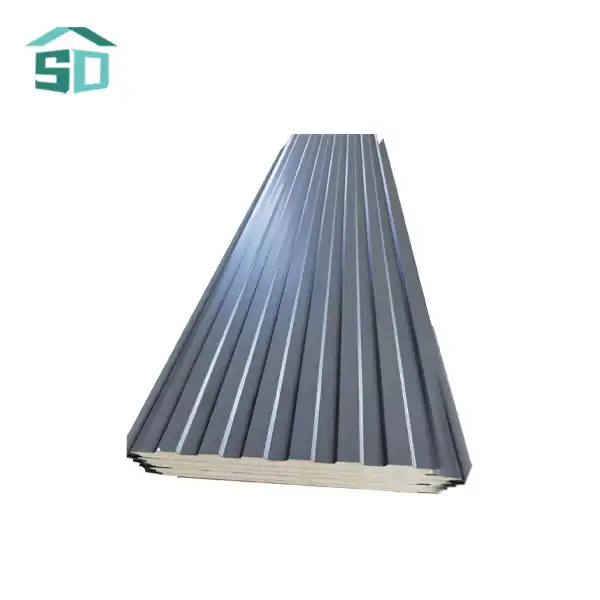

Advanced Coating Technologies

Beyond galvanization, many corrugated steel siding panels are further enhanced with advanced coating technologies. These may include:

- Paint Systems: High-performance paint systems not only add color but also provide an additional barrier against moisture and UV radiation.

- Polymer Coatings: Some panels are coated with durable polymer materials that offer superior resistance to chemicals, abrasion, and weathering.

These coatings are often available in various colors and finishes, allowing for full customization while maintaining the panels' corrosion-resistant properties.

Factors Affecting the Longevity of Corrugated Steel Panels

While corrugated steel siding panels are designed for durability, several factors can influence their lifespan and resistance to rust. Understanding these factors can help property owners and builders maximize the longevity of their installations.

Environmental Conditions

The environment in which layered steel boards are introduced plays a critical part in their performance:

- Coastal Zones: Saltwater and salt-laden discuss can quicken erosion. Boards introduced in coastal locales may require more visit support or specialized coatings.

- Industrial Zones: Regions with tall levels of discuss contamination or chemical presentation may posture extra challenges to the panels' defensive coatings.

- Climate: Extraordinary temperature changes, tall stickiness, or visit precipitation can test the limits of the panels' rust resistance.

Installation and Maintenance Practices

Proper installation and regular maintenance are crucial for preventing rust and extending the life of corrugated steel siding panels:

- Correct Installation: Ensuring proper overlap, sealing, and fastening prevents water ingress and reduces the risk of rust formation.

- Regular Inspections: Periodic checks can identify and address minor issues before they escalate into more significant problems.

- Cleaning: Gentle cleaning to remove dirt, debris, and potential corrosive substances helps maintain the protective coatings.

By adhering to manufacturer guidelines for installation and maintenance, property owners can significantly enhance the rust resistance of their corrugated steel panels.

Innovative Features Enhancing Rust Resistance in Modern Corrugated Steel Panels

As technology advances, so does the rust resistance of corrugated steel siding panels. Manufacturers are continuously innovating to improve the durability and longevity of these building materials.

Self-Healing Coatings

One of the most exciting developments in the field is the emergence of self-healing coatings. These advanced materials can repair minor scratches or damage autonomously, providing an extra layer of protection against rust:

- Microcapsule Technology: Tiny capsules filled with healing agents are embedded in the coating. When the surface is scratched, these capsules rupture and release the agents, which then fill and seal the damaged area.

- Shape Memory Polymers: These materials can return to their original shape when exposed to certain stimuli, effectively "healing" minor surface damage.

Nanotechnology Applications

Nanotechnology is opening up new possibilities for enhancing the rust resistance of corrugated steel panels:

- Nanostructured Coatings: These ultra-thin coatings provide superior barrier properties against moisture and corrosive agents.

- Nanocomposites: By incorporating nanoparticles into the coating matrix, manufacturers can create materials with improved scratch resistance and self-cleaning properties.

These innovations not only improve the rust resistance of corrugated steel siding panels but also contribute to their overall durability and longevity. As a result, modern panels can offer unmatched weather resistance and maintain their appearance for extended periods, even in challenging environments.

Conclusion

Corrugated steel siding panels have come a long way in terms of rust resistance and durability. Through advanced galvanization processes, innovative coatings, and cutting-edge technologies, these panels offer exceptional protection against rust and corrosion. While no material is entirely immune to the effects of time and weather, properly manufactured and maintained corrugated steel panels can provide decades of reliable service.

For property owners and builders looking to leverage the benefits of these rust-resistant materials, it's crucial to work with reputable manufacturers and installers. By choosing high-quality panels and following best practices for installation and maintenance, you can ensure your corrugated steel siding remains an attractive and functional part of your building for years to come.

If you're interested in learning more about our range of exterior cladding and facade solutions, including our innovative corrugated steel siding panels, we invite you to reach out to us at info@sdqsc.com. Our team of experts is ready to help you find the perfect solution for your building needs, combining durability, style, and advanced rust-resistant technologies.