The Innovative Structure of Metal Foam Sandwich Panels

Composition and Manufacturing Process

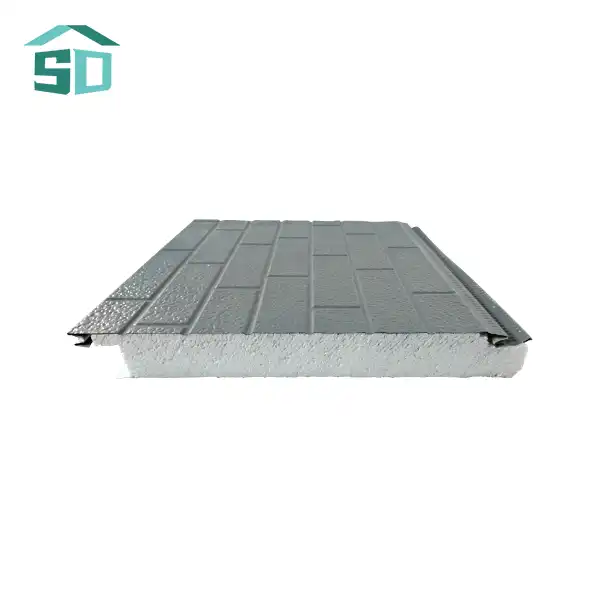

Metal foam sandwich panels consist of three main components: two metal face sheets and a metal foam core. The face sheets are typically made from high-quality steel or aluminum, while the core is composed of a specialized metal foam material. This unique structure is achieved through an advanced manufacturing process that involves carefully bonding the metal face sheets to the foam core, creating a strong and cohesive panel.

The fabricating prepare starts with the generation of the metal froth center. This is ordinarily done utilizing a assortment of strategies, such as gas infusion, powder metallurgy, or casting. The coming about froth structure is characterized by its open-cell or closed-cell arrangement, which contributes to the panel's extraordinary properties. Once the froth center is arranged, it is sandwiched between the metal confront sheets and fortified utilizing cements or other joining strategies.

Unmatched Durability and Strength

One of the key preferences of metal froth sandwich boards is their extraordinary solidness and strength-to-weight proportion. The metal froth center gives fabulous auxiliary back, whereas keeping the by-and-large weight of the board generally more. This interesting combination permits the creation of huge, durable divider boards that can withstand different natural stresses without compromising on execution.

The panels' durability is further enhanced by their resistance to corrosion and impact. The metal face sheets offer protection against external elements, while the foam core acts as a buffer, absorbing and dissipating energy from impacts. This makes metal foam sandwich panels an ideal choice for applications in harsh environments or areas prone to extreme weather conditions.

Customization Options for Unique Wall Designs

Versatile Aesthetic Possibilities

Metal foam sandwich panels offer an extensive range of customization options, allowing architects and designers to create truly unique wall designs. The metal face sheets can be finished in a variety of colors, textures, and patterns to achieve the desired aesthetic effect. From sleek, modern metallic finishes to warm, wood-like textures, the possibilities are virtually limitless.

Additionally, the panels can be fabricated in various sizes and shapes, enabling the creation of complex geometric patterns or seamless, large-scale wall installations. This flexibility in design allows for the integration of metal foam sandwich panels into a wide range of architectural styles, from contemporary minimalist structures to more traditional or eclectic designs.

Tailored Performance Characteristics

Beyond aesthetic customization, metal foam sandwich panels can also be tailored to meet specific performance requirements. The thickness and density of the foam core can be adjusted to achieve the desired level of thermal insulation, acoustic performance, or fire resistance. This allows architects and builders to optimize the panels for different applications, whether it's creating a highly insulated exterior wall for an energy-efficient building or designing a sound-absorbing interior partition for a concert hall.

Furthermore, the panels can be engineered to incorporate additional features such as integrated lighting systems, ventilation channels, or mounting points for fixtures and accessories. This level of customization enables the creation of multifunctional wall designs that not only look stunning but also serve practical purposes within the building envelope.

Applications and Benefits in Modern Architecture

Versatile Use in Various Building Types

Metal foam sandwich panels find application in a wide range of construction projects, showcasing their versatility and adaptability. They are equally suited for use in residential complexes, office buildings, villas, and public spaces such as museums or shopping centers. The panels' customizable nature allows them to seamlessly integrate into both new construction and renovation projects, including the restoration of historic buildings.

In commercial settings, metal foam sandwich panels can be used to create striking facades that enhance a company's brand identity while providing excellent thermal performance. For residential applications, the panels offer homeowners the opportunity to achieve unique exterior designs without compromising on energy efficiency or durability.

Sustainable and Energy-Efficient Solution

As the construction industry increasingly focuses on sustainability and energy efficiency, metal foam sandwich panels emerge as an eco-friendly choice for wall designs. The panels' exceptional thermal insulation properties contribute to reduced energy consumption for heating and cooling, lowering a building's overall carbon footprint.

Moreover, the durability and longevity of metal foam sandwich panels mean they require minimal maintenance and have a longer lifespan compared to traditional wall materials. This reduces the need for frequent replacements and renovations, further enhancing their sustainability credentials. The panels can also be designed with recyclable materials, aligning with circular economy principles and supporting environmentally conscious building practices.

Cost-Effective Long-Term Investment

While the initial cost of metal foam sandwich panels may be higher than some traditional wall materials, they offer significant long-term cost benefits. Their superior durability and low maintenance requirements translate to reduced lifecycle costs for building owners. Additionally, the panels' excellent thermal performance contributes to ongoing energy savings, providing a return on investment through lower utility bills over the life of the building.

The versatility of metal foam sandwich panels also allows for streamlined construction processes, potentially reducing installation time and labor costs. Their lightweight nature makes them easier to handle and install compared to heavier wall systems, which can lead to faster project completion times and lower overall construction costs.

Conclusion

Customizable metal foam sandwich panels represent a significant advancement in wall design technology, offering a unique combination of aesthetic flexibility, structural performance, and energy efficiency. As the demand for innovative and sustainable building solutions continues to grow, these versatile panels are poised to play an increasingly important role in shaping the future of architecture and construction.

For those seeking to elevate their building projects with cutting-edge wall designs, metal foam sandwich panels provide an unparalleled opportunity to create visually striking, high-performance structures that stand the test of time. To learn more about how these innovative panels can transform your next project, or to explore the full range of exterior cladding and facade solutions available, contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to help you bring your unique wall design visions to life.